7

4.2 Electrical connection

Attention

:

1. All electrical connection has to be carried out by qualified and licensed operators.

2. Please turn off the distribution box switch and make sure safety before any electric connection.

3

.

Please use required standard cables.

4

.

Don’t touch with wet hands.

5

.

Don’t place heavy items on cables.

6

.

Tap water pipe, house rebar may be in poor ground condition. Please don’t use them as safe ground lead.

7

.

Every welder is equipped with an air switch or fuse.

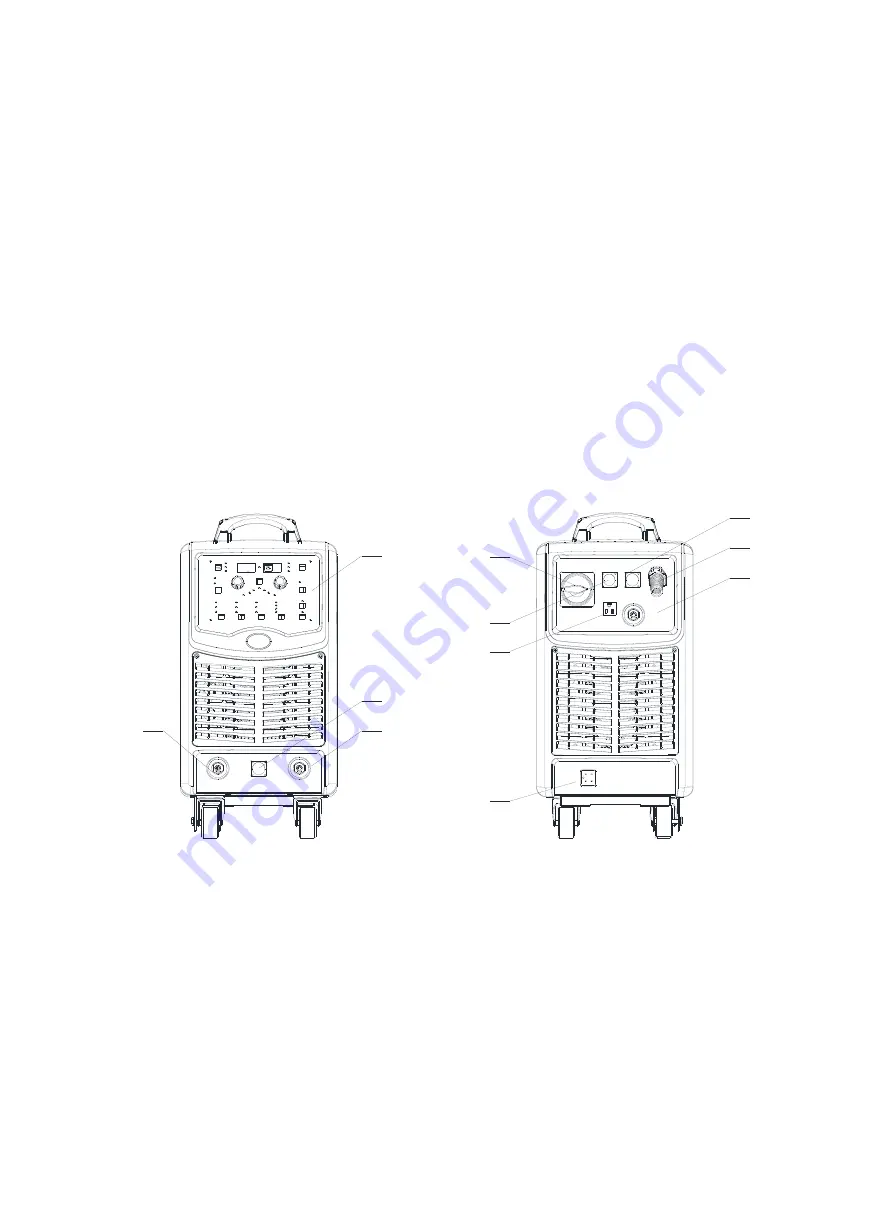

4.3 Front & back panel introduction

1

4

2

3

4

2

1

3

5

6

7

Fig 4.1

Front panel description:

1.

Digital front panel(parameters selection,

setting and display.)

2.

Wire feeder control cable connector

3.

Quick socket for positive output (connect wire

feeder or MMA electrode holder)

4.

Quick socket for positive output(connect

MMA earth clamp)

Back panel description:

1.

Breaker

(

air switch

)

2.

Wire feeder control cable connector

3.

Software upgrade interface

4.

3 phase power cable

(

4×6mm

2

/4×4mm

2

)

5.

Socket for gas heater (Not for any other use

except heating gas )

6.

Quick socket for positive output(connect wire

feeder)

7.

Cooler interface

Summary of Contents for MIG 350P

Page 13: ...11 4 6 2 Separated machine installation Figure 4 3 ...

Page 19: ...17 3 Operation modes Table 5 2 DC MIG operation modes Modes Sketch map 2T 4T ...

Page 20: ...18 Repeat Spot weldin g 5 2 3 Pulse MIG 1 Synergic and Separate ...

Page 22: ...20 2T with initial crater 4T ...

Page 23: ...21 4T with initial segmen t Special 4T pro gram 4T ...

Page 40: ...38 7 Wiring Diagram ...

Page 42: ...40 ...