24

Arcing

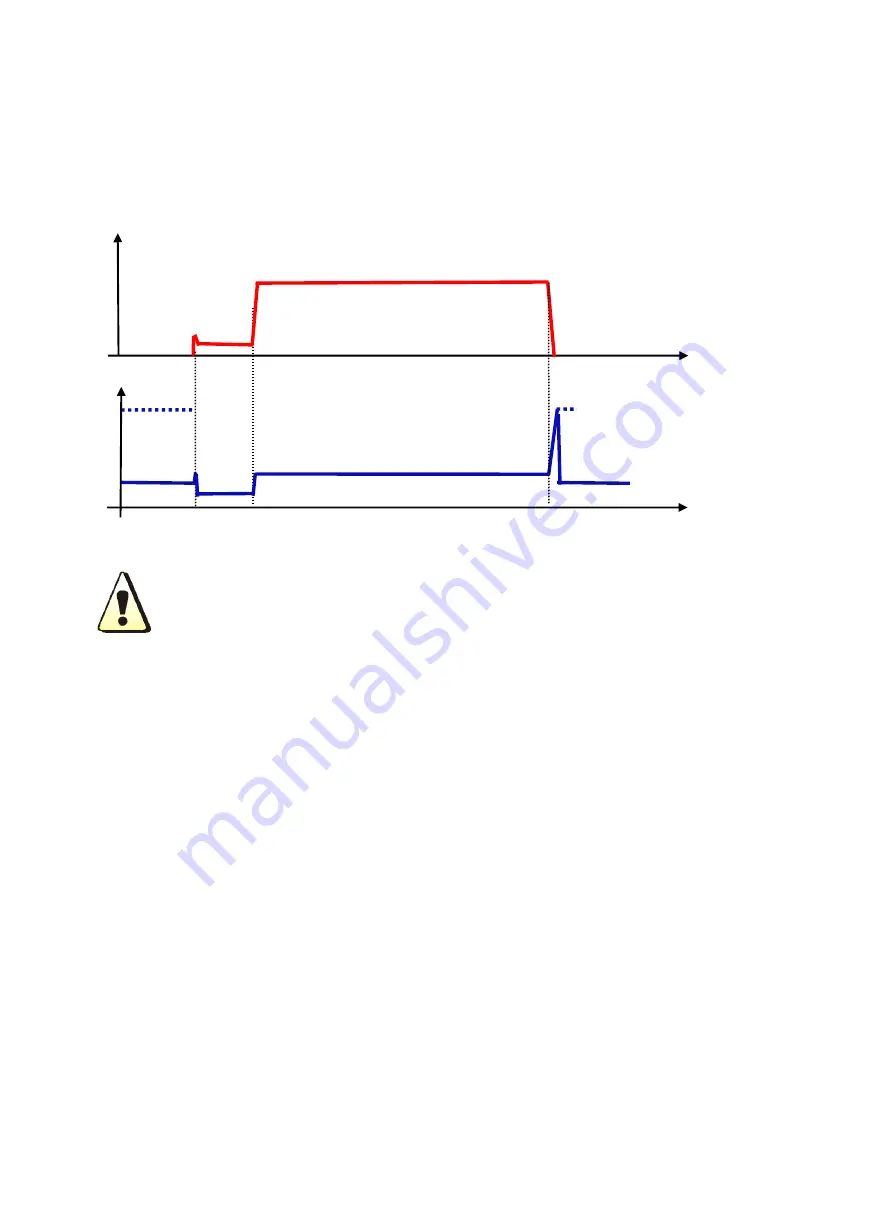

5.2.5 Lift-TIG welding

Simple TIG, namely lift TIG, is simple DC TIG realized by lift TIG or scratch TIG with help of necessary gas circuit

device, but operation modes and functions of torch trigger for common TIG are unavailable for simple TIG.

Simple TIG can set only welding current: 30A~500/350A, while fixed shorted current is 25A.

I

I

U U

0

U

VRD

Fig5.5 Simple TIG processing

Warning! During welding, it is forbidden to pull off any plug or cable in use,

or it will lead to life-threatening danger and severe damage of the machine.

5.3 Selection and adjustment of internal parameters

●

Please be careful of the internal parameters that are applied to factory calibration and adjustment on the basis

of special requirements of professional personnel, otherwise it will result in welder failure.

5.3.1 Adjustment on burn-back coefficient

Under pulse MIG, preset burn-back parameters in the welder usually can satisfy normal burn-back removal of

metallic ball, but users can adjust burn-back coefficient if necessary. Below are adjustment steps:

1

、

Select welding post-flow segment;2

、

Switch time LED to speed/board thickness LED. At this time, the left

segment displays 1.00; 3

、

It can be adjusted between 0.50~1.50 by left encoder. Within 0.50~1.50, if it is decreased,

burn-back time is long, if it is increased, burn-back time is short. This parameter will be applied to all welding wires and

it is 1.0 by default after welder is restarted.

Short circuit

Summary of Contents for MIG 350P

Page 13: ...11 4 6 2 Separated machine installation Figure 4 3 ...

Page 19: ...17 3 Operation modes Table 5 2 DC MIG operation modes Modes Sketch map 2T 4T ...

Page 20: ...18 Repeat Spot weldin g 5 2 3 Pulse MIG 1 Synergic and Separate ...

Page 22: ...20 2T with initial crater 4T ...

Page 23: ...21 4T with initial segmen t Special 4T pro gram 4T ...

Page 40: ...38 7 Wiring Diagram ...

Page 42: ...40 ...