36

1.2

7

1

270-180

29-31

38-43

N

1.4

1

340-360

31-33

48-53

N

1.6

1

370-390

33-35

60-70

N

1.4

9

1

260-280

27-26

22-26

Y

12

1

320-340

30-32

38-42

N

2

320-340

30-32

40-44

N

3

320-340

29-31

48-52

N

1.2

9

1

260-280

22-29

23-27

N

12

1

290-310

30-32

33-37

N

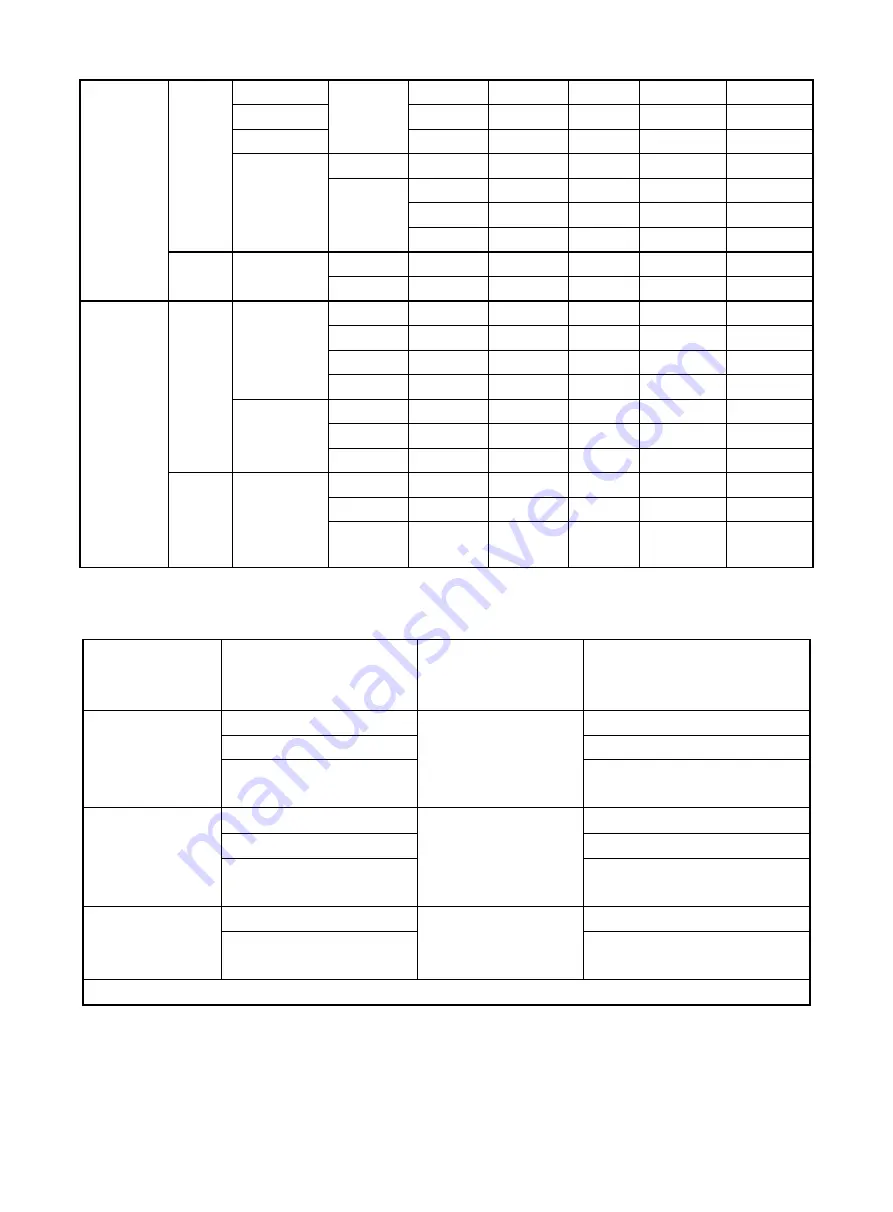

Titanium

calsium

1.2

2

290-310

30-32

27-31

Y

4

-

210-230

26-28

68-72

-

6

-

260-280

28-30

48-52

-

8

-

290-310

29-31

33-37

-

1.4

4

-

250-270

27-29

68-72

-

6

-

310-330

30-32

48-52

-

8

-

340-360

32-34

33-37

-

Vertica

l angle

weldin

g

1.2

4

-

170-190

21-23

48-52

-

6

-

190-210

22-24

48-52

-

8

-

210-230

22-24

43-47

-

If welding conditions are not suitable, problems in table 6-8 will happen.

Table 6-8 Common MIG failure table

Inappropriate

welding

conditions

effects

Inappropriate welding

conditions

effects

Long wire

extension

Arc is long

Arc voltage is too high

Arc is too long

Weld bead is wide

Weld bead is wide

Gas shielding effects will be

poor

Bigger penetration and excess weld

metal

Short wire

extension

Arc is short

Arc voltage is too low

Sticking, spatter

spatter

Weld bead is narrow

Smaller penetration and excess weld

metal

Welding current is

too big

Weld bead is wide

Welding speed is too

high

Weld bead is narrow

Bigger penetration and excess

weld metal

Smaller penetration and excess weld

metal

Wire extension

:

the distance between torch contact tip and workpiece.

Summary of Contents for MIG 350P

Page 13: ...11 4 6 2 Separated machine installation Figure 4 3 ...

Page 19: ...17 3 Operation modes Table 5 2 DC MIG operation modes Modes Sketch map 2T 4T ...

Page 20: ...18 Repeat Spot weldin g 5 2 3 Pulse MIG 1 Synergic and Separate ...

Page 22: ...20 2T with initial crater 4T ...

Page 23: ...21 4T with initial segmen t Special 4T pro gram 4T ...

Page 40: ...38 7 Wiring Diagram ...

Page 42: ...40 ...