2

Contents Page

Before starting any cutting activity thoroughly read the operating manual first to familiarize yourself with the safe and correct

operation of your Jasic plasma machine. Always ensure that you have suitable eye protection and protective clothing. Also take

the necessary steps to protect any persons within the cutting area.

Index

Page Number

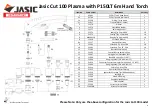

Jasic Cut 100 with P150LT Plasma Torch Overview

3

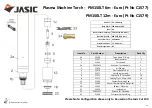

P150LT Consumable Breakdowns

4

P150LT Torch Information

9

Machine torch option

11

Safety Information

12

General Plasma Cutting Information

13

Stand

-

off Cutting

14

Drag Cutting

15

Piercing

16

Bevelling

16

Gouging

17

Plasma Cutting Tips and Techniques

18

Plasma Machine Gas Supply

-

Compressed Air

19

Contact Details

20