17

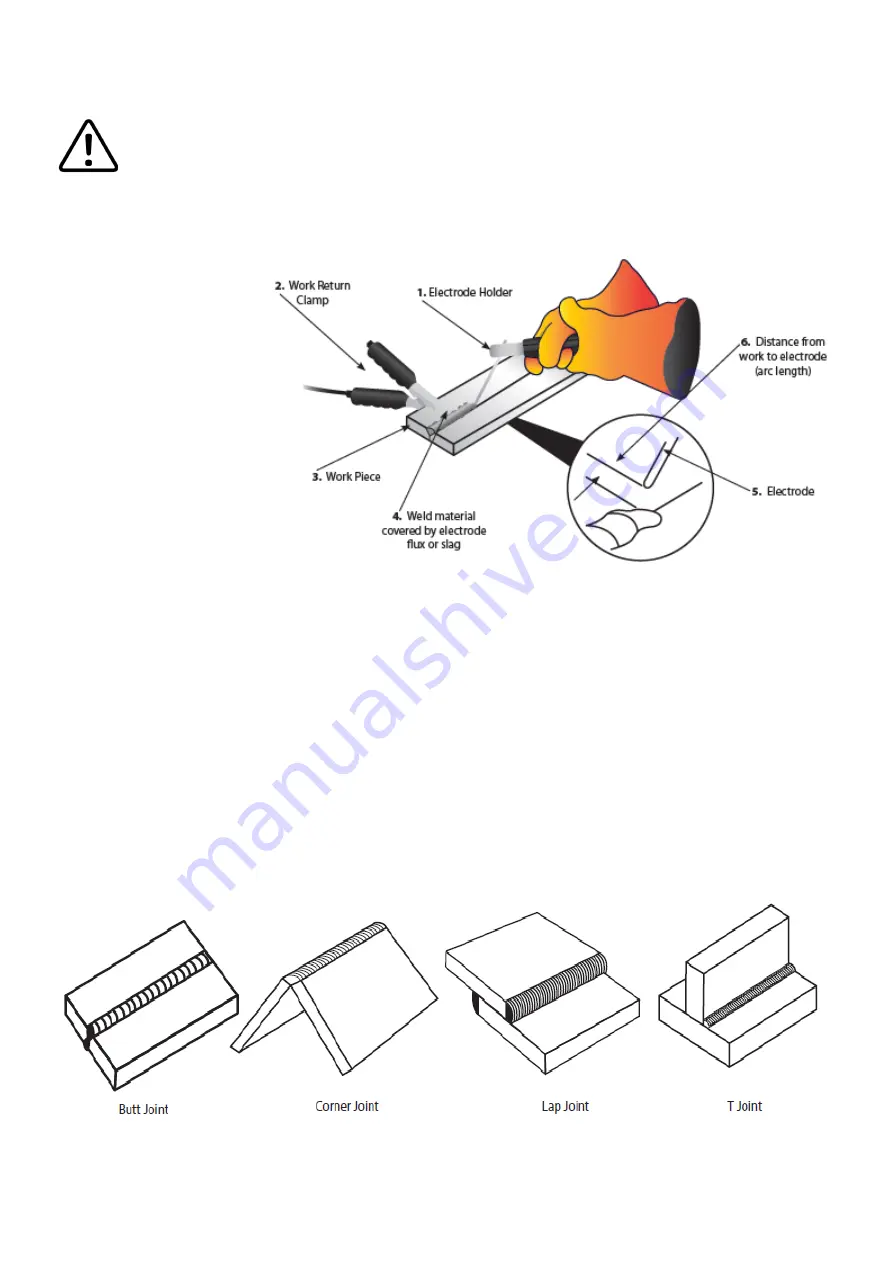

GUIDE TO MMA WELDING

Before starting any welding activity ensure that you have suitable eye protection and

protective clothing. Also take the necessary steps to protect any persons within the welding

area.

MMA process tips and guides

Typical welder set up

1. Electrode holder

2. Work return clamp

3. Work piece

4. Weld material covered

by electrode flux or slag

5. Electrode

6. Distance from work to

electrode (arc Length)

Welding current will flow in the circuit as soon as the electrode contacts the work piece. The welder

should always ensure a good connection of the work clamp. The nearer the clamp is placed to the

welding area the better.

When the arc is struck the distance between the end of the electrode and the work will determine the

arc voltage and also affect the weld characteristic. As a guide the arc length for electrodes up to 3.2mm

diameter should be around 1.6mm and over 3.2mm around 3mm.

Upon completion of the weld the welding flux or slag will need to be removed usually with a chipping

hammer and wire brush.

Joint form in MMA

In MMA welding, the common basic joint forms: butt joint, corner joint, lap joint & T joint.