Page 36

balance is equal to the AC frequency. Therefore, the frequency range of mixed TIG welding is

1Hz to the AC frequency/10Hz, and the user can select any frequency within the range.

When the AC frequency changes, the AC frequency/actual frequency of the current mixed

TIG welding is equal to the frequency division factor, and is updated. After the frequency

division factor is determined, the current AC frequency/frequency division factor is equal to

the actual frequency of the current mixed TIG welding and is saved, so it does not change.

After setting the AC frequency and mixed TIG frequency, the frequency division factor is

determined as the AC frequency/mixed TIG frequency. Example: If the AC frequency is set to

100Hz, the mixed TIG frequency range is 1-10Hz. Set the AC frequency to 100Hz at the first

time and then the mixed TIG frequency is set to 5Hz for the first time, the current frequency

division factor is 100/5=20. If the AC frequency is updated to 70Hz, the frequency division

factor is 70/5=14; that is, the frequency division factor is variable, but the mixed TIG

frequency is constant.

In other words, the AC frequency affects the frequency range of

mixed TIG welding, but after the mixed TIG frequency is determined, it is no longer

affected by the AC frequency.

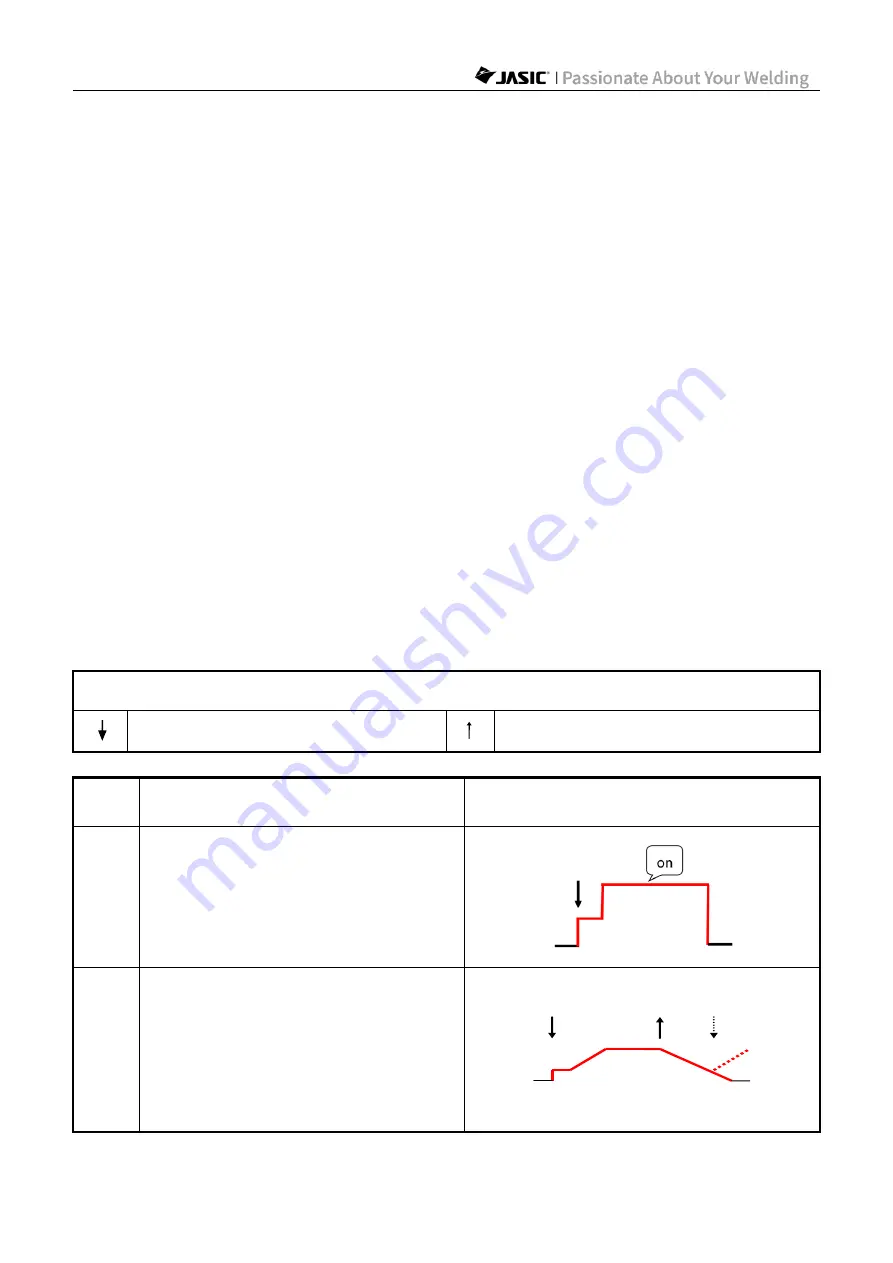

7.3.6 Welding mode description of TIG welding torch

TIG operation mode has a special convention, which specifies the mode or method of

controlling the welding current change by different operations of torch trigger during TIG (DC,

pulse, AC TIG, or mixed TIG) welding. The introduction of TIG operation strengthens the

application of the torch trigger remote control function, so the user can obtain a practical

welder remote controller without additional investment.

The TIG mode is determined according to the process requirements and operator preference.

The symbols in the diagram are as follows:

Legend for commonly-used torch trigger operations

Press the torch trigger

Release the torch trigger

Mode

No.

Operation Schedule

Torch trigger operation and typical DC TIG

current curve

1

Spot welding mode:

1. Press the torch trigger to start the arc

to the set value;

2. The arc extinguishes after the spot

welding finishes running for the set

time.

2

2T mode:

1. Press the torch trigger to increase

the arc up to the designated peak

current

2. Release the trigger to slowly

extinguish the arc

3. If the trigger is pressed again before