Page 39

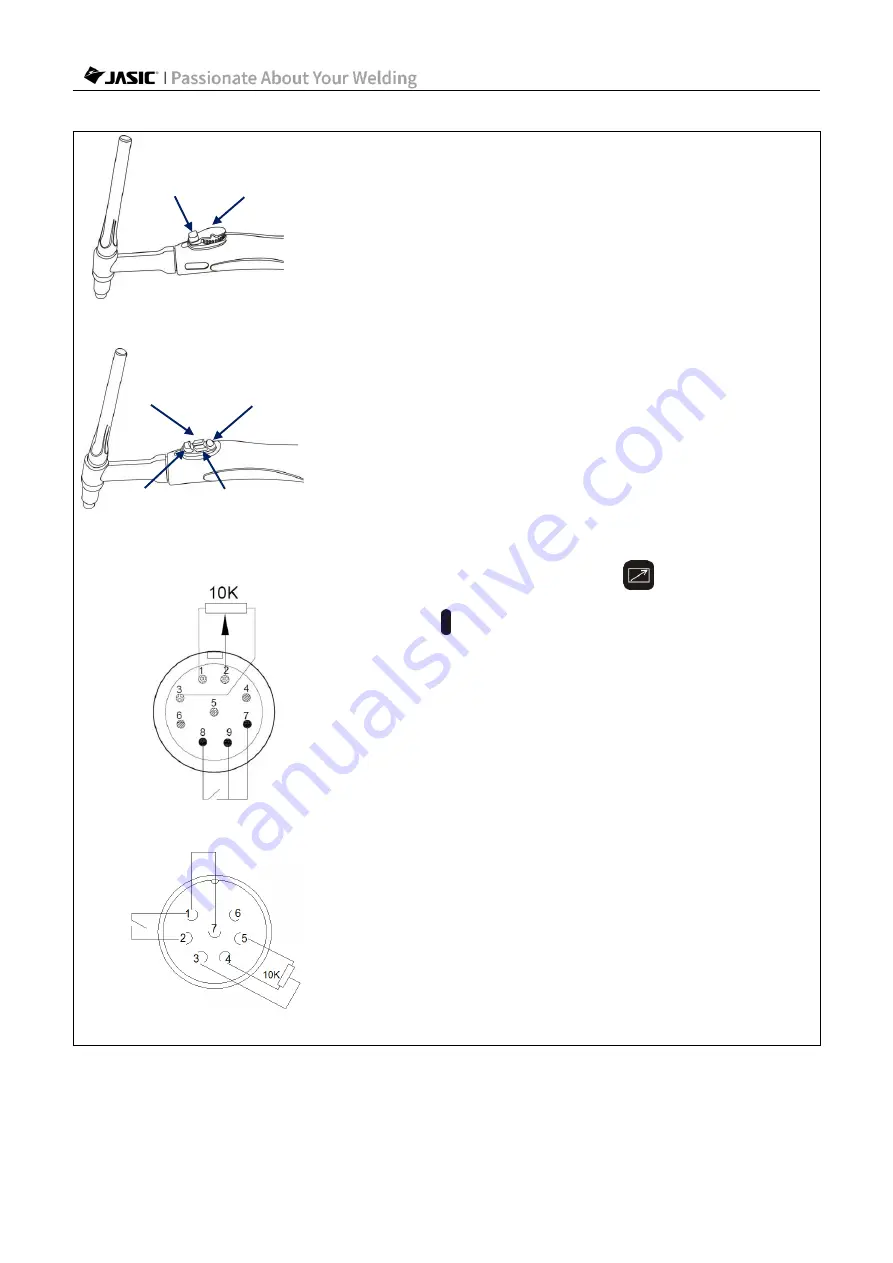

7.3.8 Use of wired welding torch

9-pin aviation socket of analog torch

7-pin aviation socket of analog torch

1. Wired welding torch include digital and analog types,

as shown in the following figure.

2. Use a dedicated cable to connect the analog welding

torch to pins 1, 2, 3, 8 and 9 of the torch trigger's aviation

socket on the front panel of the welder; connect pin 7 of

the torch to pin 9.

Pin 2 is the common potentiometer port. When the torch

control value is 0 and the current value is at the

minimum, the resistance of pins 1 and 2 is 10kΩ, and of

pins 2 and 3 is 0Ω; when the roller value is at the

maximum and the current value is at the maximum, the

resistance of pins 1 and 2 is 0Ω, and of pins 2 and 3 is

10kΩ.

3. Use a dedicated cable to connect the digital welding

torch to pins 4, 5, 6, 8 and 9 of the torch trigger's aviation

socket on the front panel of the welder. Pin 4 decreases

the value, pin 5 increases the value, and pin 6 is 2T/4T.

Pin 7 of the digital torch is reserved.

4. Under no load, press the key

to turn on the

indicator . At this time, the welding torch is in torch

control mode.

5. When using the analog welding torch, set the welding

parameters on the panel to start welding. During

welding, the potentiometer can be used to adjust the

welding current from the minimum to the set value.

6. When using the digital welding torch, the Parameter

Selection key on the torch can be used to switch the

adjustment parameter; Parameter Increase and

Parameter Decrease can be used to adjust the

parameter value; and Torch Trigger on the welding torch

can be used to control the output mode.

6.1 Wiring method:

Torch trigger: Pins 8-9; +: Pins 5-9; -: Pins 4-9

Functional parameter selection: Pins 6-9 (Pin 9 is GND)

Note: The analog and digital welding torches are

optional. Specify before placing an order if required.

Torch

trigger

Current

adjustment

potentiometer

Analog welding gun

Parameter

increase

Parameter

selection

Torch

trigger

Parameter

decrease

Digital welding gun