Page 43

disassembly and assembly

The argon gas is impure

Replace with qualified argon gas

The gas flow is too large or small

Adjust the gas flow properly

Arc is started

between the

electrode holder

and tungsten

electrode or

welding torch

The collet and tungsten electrode

have poor contact, or arc is

started when the tungsten

electrode contacts the base metal

Replace the collect or repair

The collet and welding torch have

poor contact

Connect the collect and welding torch

properly

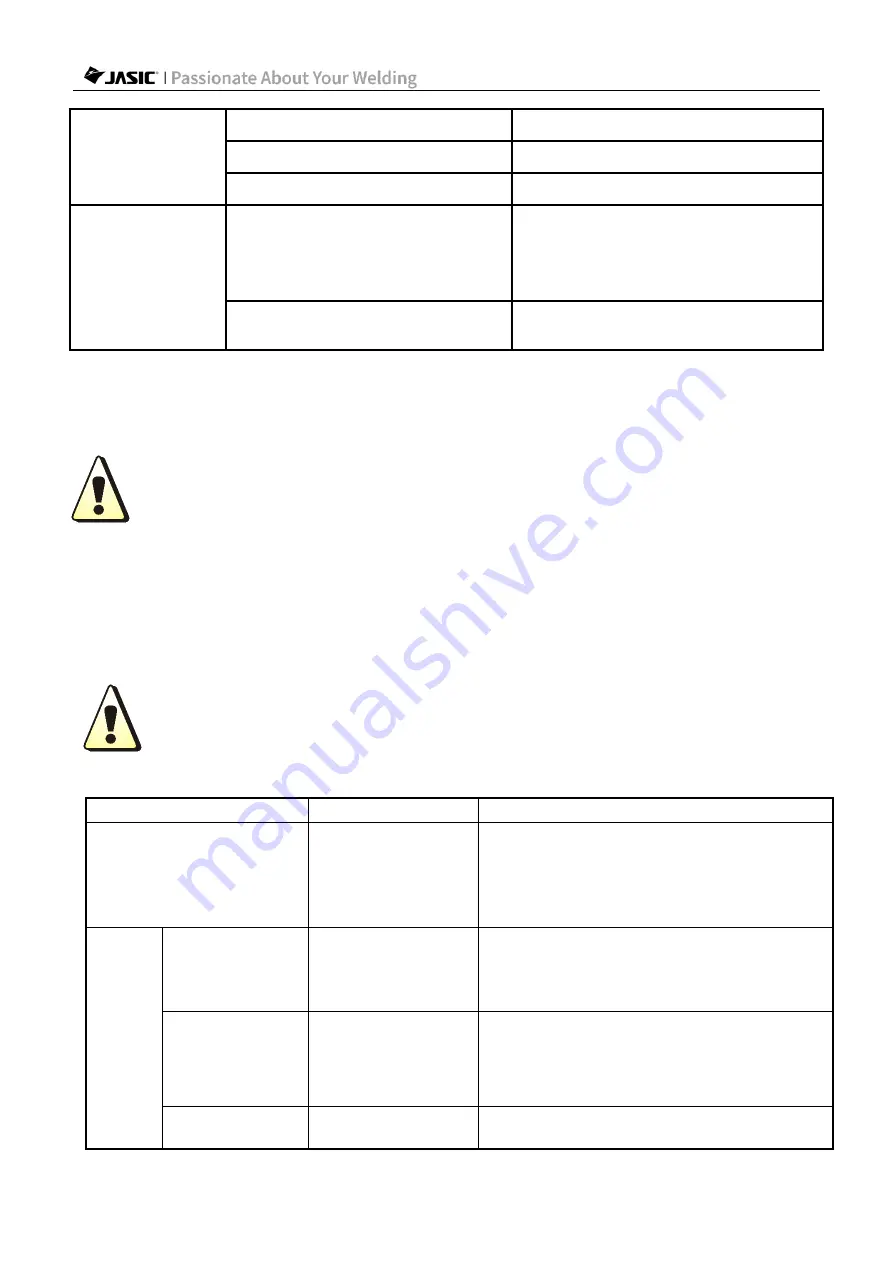

9. Troubleshooting

Warning! Before arc welding machines are dispatched from the factory, they

have already been checked thoroughly. The machine should not be tampered

with or altered. Maintenance must be carried out carefully. If any wire

becomes loose or is misplaced, it may be potentially dangerous to user! Only

professional maintenance personnel should repair the machine!

Ensure the power is disconnected before working on the machine. Always

wait 5 minutes after power switch off before removing the panels.

9.1. Common malfunction analysis and solution

The symptoms listed here may be related to the accessories, gas,

environmental factors, and power supply you use. Please try to improve the

environment and avoid such situations.

Elimination of general problems in MMA

Symptom

Reasons

Troubleshooting

After startup, the fan does

not turn or the wire feeding

speed is abnormal

The air temperature

may be too low or

the fan may be

damaged

When the temperature is too low, leave the

machine work for a while. The temperature

in standby will rise, then fan will resume

normal operation. If it is still not working, it is

necessary to replace the fan.

MMA

Hard to start the

arc

Arc hot start current

is low

Or the hot start time

is short

Increase arc start current or arc start time

Unstable arc or

excessive molten

pool during arc

start

Arc start current is

high

Or the arc start time

is long

Reduce arc start current or start time

appropriately

Cannot start

The power cord is

not connected

Connect the power cord