Jason International, Inc. •

501.771.4477

Page 4 of 16

Customer Service : 800.255.5766

Copyright © 2014 Jason International.

10. High Flow fill fittings have been installed on the sidewall

adjacent to the overflow drain. These can be attached

to any mixing valve. 3/4” inlet rough in plumbing is

recommended with 3/4” mixing valves to provide a flow

rate of approximately 20GPM. If a deck mounted fill spout

is preferred, install per manufacturer’s instructions and

leave the high flow fill fittings with their factory installed

plugs in place. A vacuum breaker may be required.

Follow all required plumbing codes during installation.

(

see Figure 3.)

11. Before finishing the installation, it is recommended that

the bath be water tested (filled and operated), and the

bath and plumbing be inspected for leaks. Refer to the

OPeRaTING INSTRuCTIONS

for testing.

NOTe:

Before water testing the bath make sure the

pump unions are hand tight.

Do not over tighten or use

a pipe wrench. This will damage the unions and cause

leaking. If the unit leaks with the unions hand tight, then

loosen the union(s) and check the O-ring seal to ensure

it is properly seated.

installation instRUCtions (cont.)

12. The acrylic surface of this bath has been provided with a

protective film which helps protect the bath during shipment

and installation. Additonal protection may also be required

to protect the acrylic surface during installation. If the bath

is tiled in, remove the necessary portion of the film when

installing the tile.

13. After installation, remove the film and all loose debris

inside the bathwell and around the blower. Construction

plaster or excess grout can be removed with the use of

a wood (edge) trowel. Paint or tar stains may need to be

removed with a cleaner such as paint thinner, turpentine,

or isopropyl alcohol (rubbing alcohol).

14. Never allow cleaner the to soak against the surface

for long periods of time. Always rinse the surface

immediately following the use of cleaners.

nOTe:

Follow

the manufacturers instructions for safely using these

or similar products.

If the surface becomes scratched

or dulled, it may be restored by using a quality plastic

polish, i.e., Novus Plastic Polish No. 2.

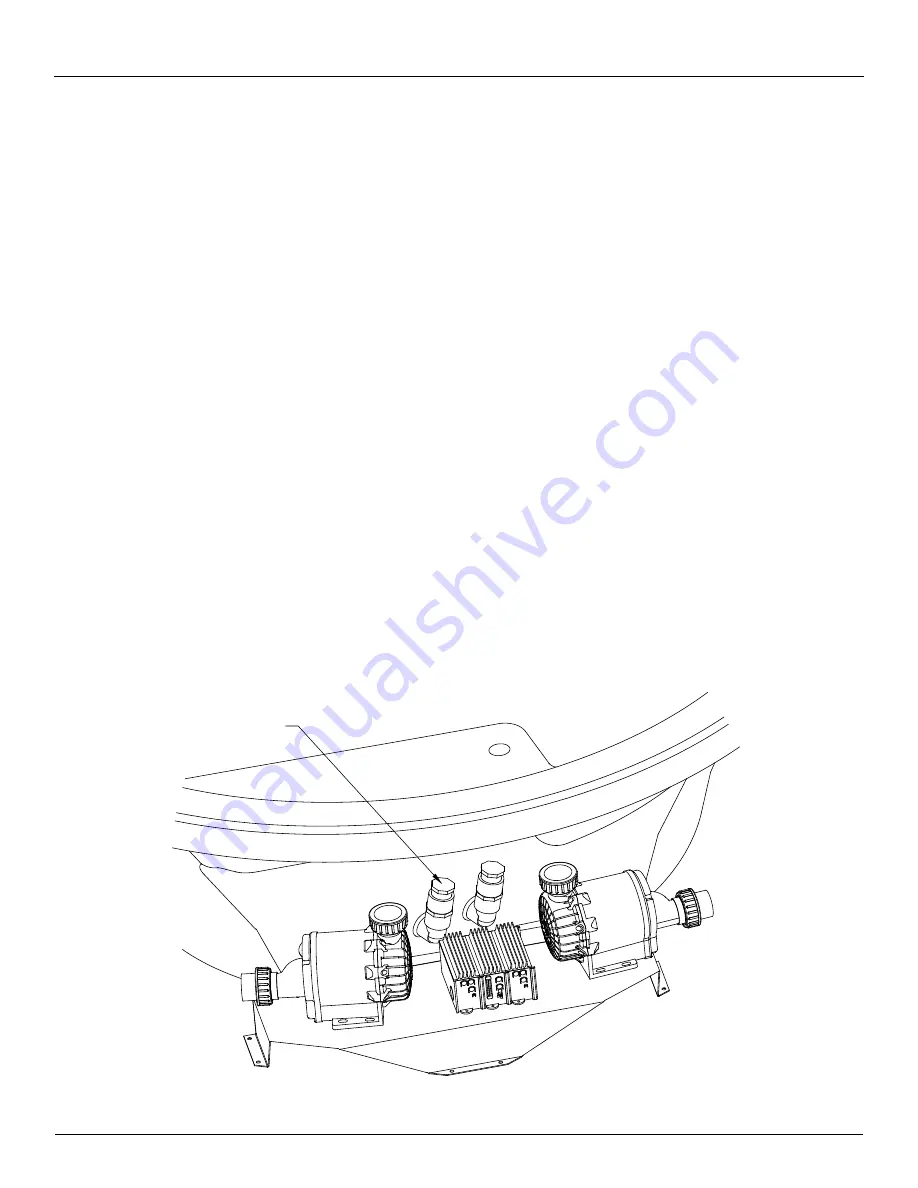

Figure 3

PLUG 1" MPT

REMOVE TO

CONNECT (2)