Jason International, Inc. •

501.771.4477

Page 3 of 9

Customer Service : 800.255.5766

INSTALLATION

See the

USER MAINTENANCE INSTRUCTIONS

section

of this owner’s manual, prior to installation, for humidity and

mold prevention suggestions.

1.

Finish Frame:

A finish frame under the shell rim should

also always be constructed to support the bath deck and

insure proper drainage toward the bath well. This frame is

not intended to support the full bath weight

(see Figures

1 & 2)

.

Jason offers a removable lateral skirt for most baths.

The skirts are available in matching acrylic colors and

provide convenient access to bath equipment as well as an

excellent finished appearance. However, if Jason’s lateral

skirt is not used, an access panel MUST be provided to

enable final electrical connections and service. Please

refer to the minimum recommended access panel size

in

Table 1 - Specifications.

If a Jason lateral skirt is to be used, the bath deck must

be leveled at 20.5” (52cm) from the support floor or the

skirt will not fit properly.

CAUTION: Make sure the support frame is drilled

and/or notched as needed to assure that the ON/

Off air actuator switch and air tube are not bound

or pinched.

Allow ample clearance for the pump.

Whirlpools with

optional front pump mounts may require a minimum of

1” clearance beyond the front and pump side lip of the

bath to allow clearance of the pump.

CAUTION: Ambient temperature under the bath

where the pump and electronics are installed must

not exceed 122°F (50°C).

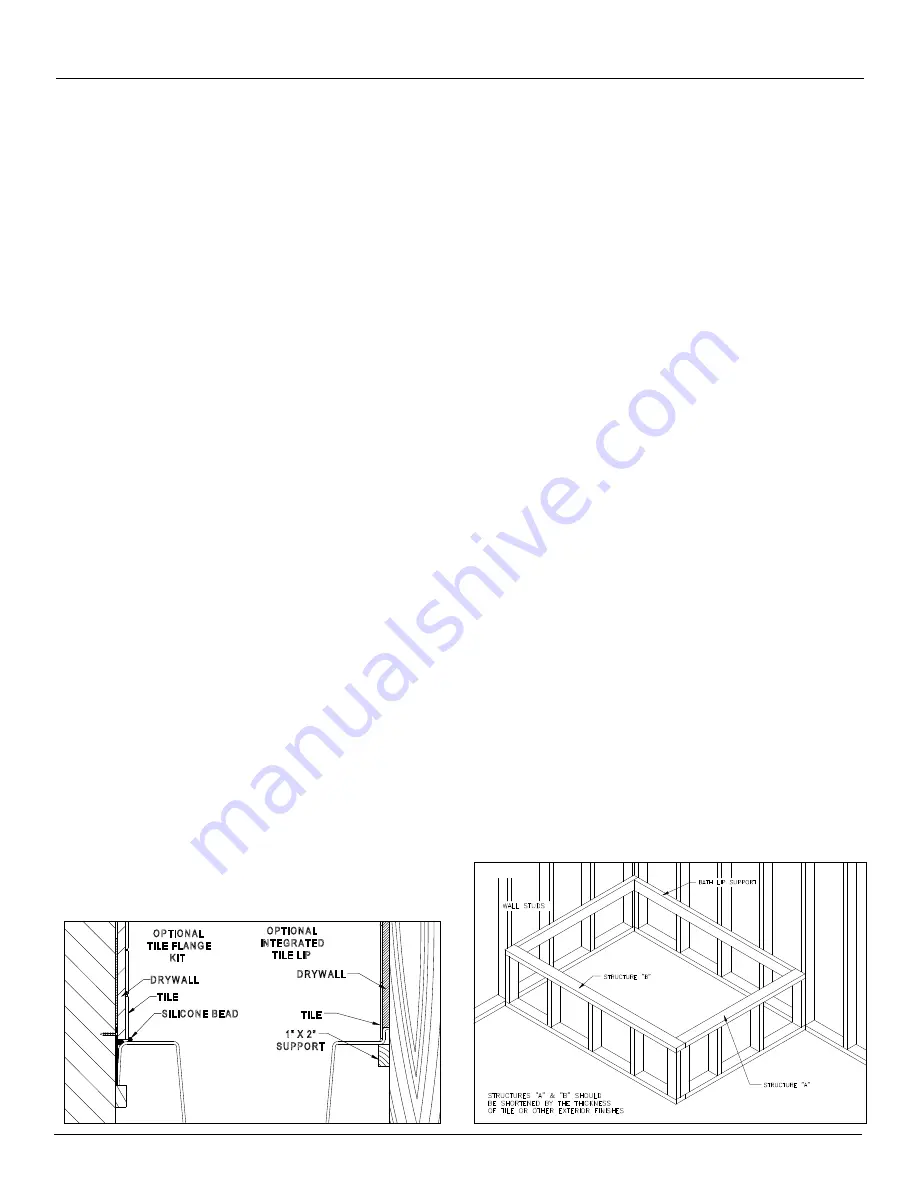

2. 100% Silicone with mildew resistant properties should be

applied between the water resistant backer board and

the deck of the bath.

NOTE:

If you use a tile flange kit,

modify the framing to support the bath lip as shown in

Figure 1

.

3. Install the drain and overflow assembly to the bath shell

according to the instructions provided with the drain and

position the bath in the area of intended installation.

4. Finish plumbing rough-in of drain and overflow assembly.

At this time, considerations should be made for the

position and mounting of the faucet set, as well as all

related plumbing.

5.

Remove the packing board before installing the bath.

The bath is equipped with separate bath equipment

support bases which are joined for shipment with packing

boards. Detach the packing board from the bath and from

underneath the equipment.

WARNING: Any modification to the equipment is

not recommended and will void the Manufacturer’s

warranty.

6. I

nstall the bath level for proper drainage.

Jason baths

are designed to be supported at the base of the bath. If

the floor is smooth and level, the baths’ Level Form™

Base will provide proper drainage and support

(See

Figure 3)

.

7. Mortar is required when the subfloor is not smooth and

level; when additional sound insulation is desired; or when

the bath is installed in a drop-in application. In alcove

installations, a bed of mortar may also be recommended

to aid in leveling the bath.

Note:

Do not use a sand bed

to install or level the bath.

8.

Secure the bottom of all equipment mounts so that it

is level with the bottom of the bath.

Position the bath

in the area of intended installation and cut the equipment

support strap(s) to allow the equipment to rest firmly

on the floor. We recommend securing the equipment

mounts to the floor with removable fasteners for ease

of servicing.

9.

Protect the acrylic bath surface from damage during

installation with a suitable material, i.e., cardboard

and/or plastic film.

The acrylic surface of this bath has

been provided with a protective film which helps protect the

bath during shipment and installation. Additional protection

may also be required to protect the acrylic surface during

installation. If the bath is tiled in, remove the necessary

portion of the film when installing the tile.

INSTALLATION INSTRUCTIONS (cont.)

Figure 1

SILICO NE BEAD

TILE

DRYW ALL

DRYW ALL

TILE

O PTIO NAL

TILE FLANG E

KIT

O PTIO NAL

INTEG RATED

TILE LIP

1" X 2"

SUPPO RT

FIG . 2

Figure 2