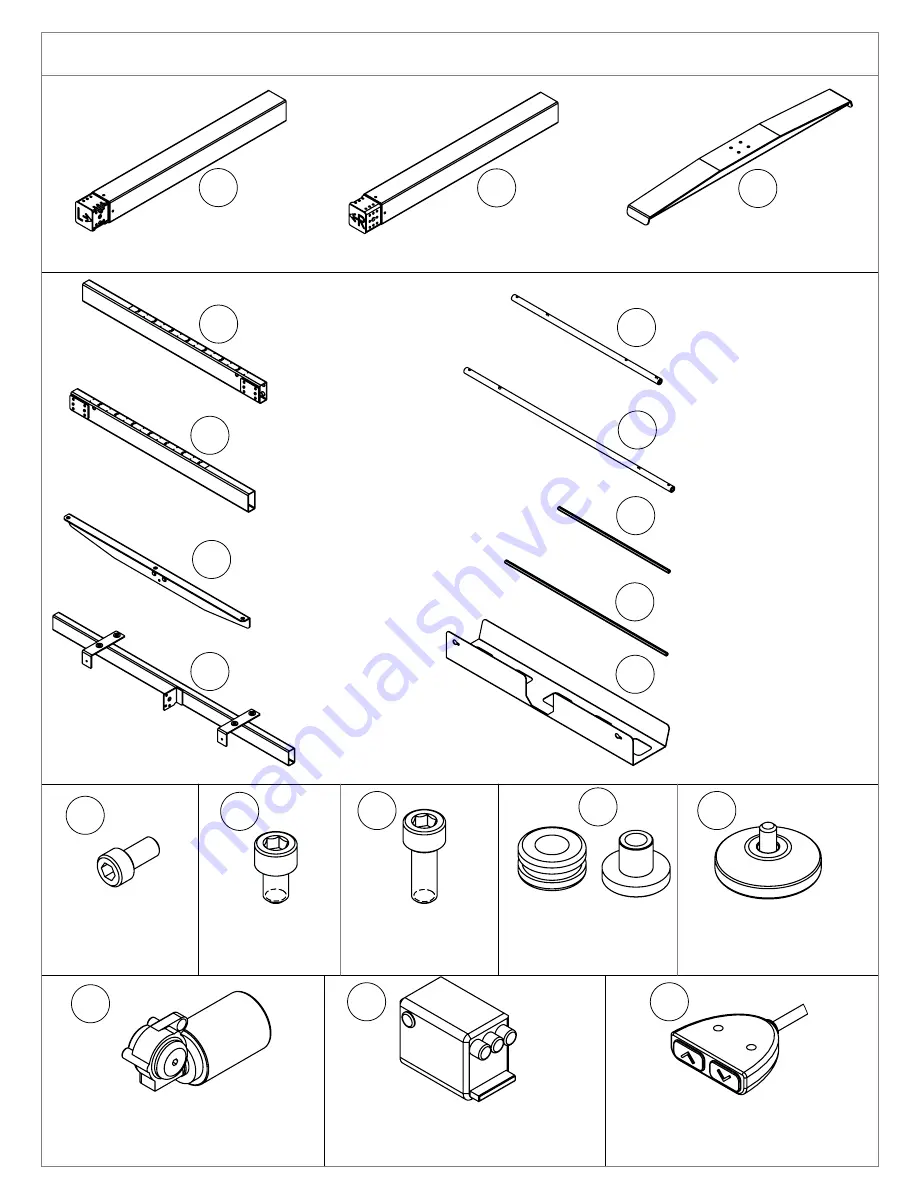

Component List - ST SUPREME E23T

03

10

11

18

17

19

13

08

15

01

02

16

04

05

07

12

09

06

AR

20

14

Axle Drive L390mm

ET-00-309

Qty : 2

Hex Shalf L295mm

ET-00-303

Qty : 2

Hex Shalf L430mm

ET-00-307

Qty : 1

Screw M5 X L10

Qty : 14

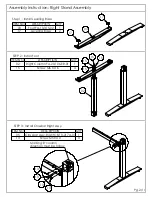

Left Column

FA-20-106-L-01

Qty:1

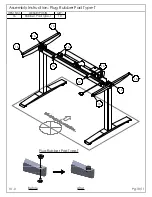

Crossbar Motor Model

CB-10-219-00

Qty : 1

Cable Tray

FA-00-220B-00

Qty : 1

Right Column

FA-20-106-ER-01

Qty: 1

Foot

FA-10-315-02

Qty: 2

Crossbar Assy. Left

CB-10-217B-01

Qty: 1

Screw M6XL10

Qty : 3

Leveling Base

Qty: 4

Control Box

TC2B

Qty : 1

Motor

TGM1-2252-002

Qty : 1

Handset TH14

Qty : 1

Rubber Pad Type-T

Qty: 10

Crossbar Assy. Right

CB-10-217A-01

Qty: 1

Axle Drive L550mm

ET-00-306

Qty : 2

Side L Plate

FA-00-119-01

Qty: 2

Screw M6 X L16

Qty : 8