________________________________________________________________________________________________________________________________________________________________

CN3600 Setup & Operation Manual Revision : 6/2020

40

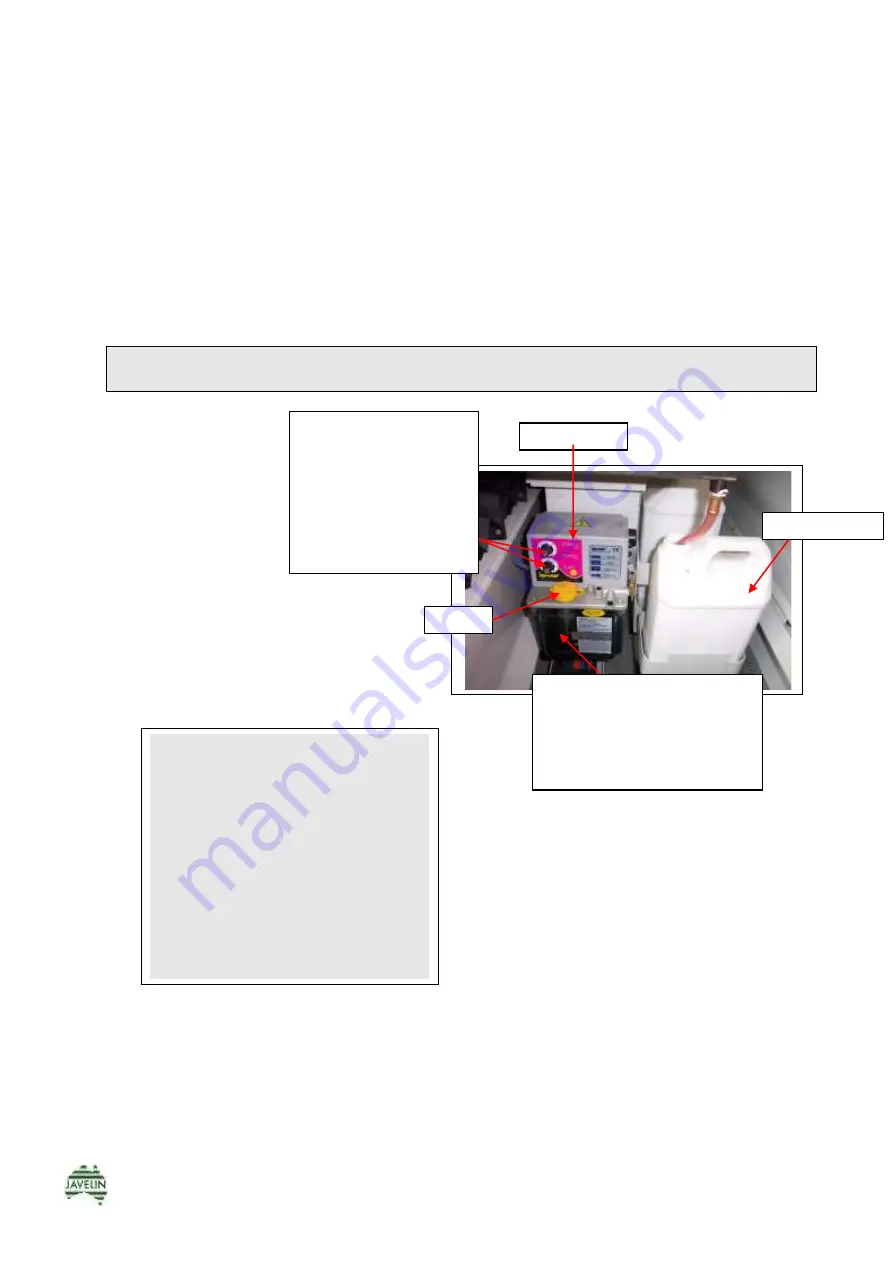

3.13 AUTO LUBRICATION SYSTEM

The J3600 machine is fitted with an Automatic Lubrication System to the linear runner

blocks; the Left & right traversing ballscrew and the forward retract ballscrew. The

lubricator is located at the rear of the machine behind the water drain bottle.

The auto lubricator is fitted with an alarm which well sound when the oil reservoir reaches

the low level mark. The machine will cease to operate.

The lubrication bottle should be filled with an equivalent oil as specified on the

manufacturers label on the oil reservoir (see copy manufacturers label below).

Note: The knife pivot ballscrew nut is fitted with a grease nipple and it should be greased

monthly.

Fig 3.13 Auto Lubricator System

Lubricator Controls

Top Knob controls the lubrication

duration (This is preset at 10

seconds by the factory and should

not be altered)

Lower

Knob

controls

the

frequency of lubrication (This is

preset at 150min by the factory

and should not be altered)

Water Drain bottle

Auto Lubricator

Fill Cap

Low & High Level

Markings on container

NOTE

DO NOT OVERFILL

ATTENTION:

Ensure new oil used. Used/recycle oil is

prohibited.

Clean the oil tank every two months and also

clean or change the oil inlet and the filter of

gear pump.

Suggested lubricant is dependant on

temperature difference between summer &

winter.

Use a good quality oil with a viscosity of

between 46-150 in summer and with a viscosity

of between 32-68 in winter.

We suggest using leading brand of oil, eg

MOBIL, CPC or CALTEX.