JAVELIN MACHINERY (AUSTRALIA)

J800 /J900 OPERATION MANUAL

(incl. Troubleshooting Machine Problems)

JULY 2016

Page 19

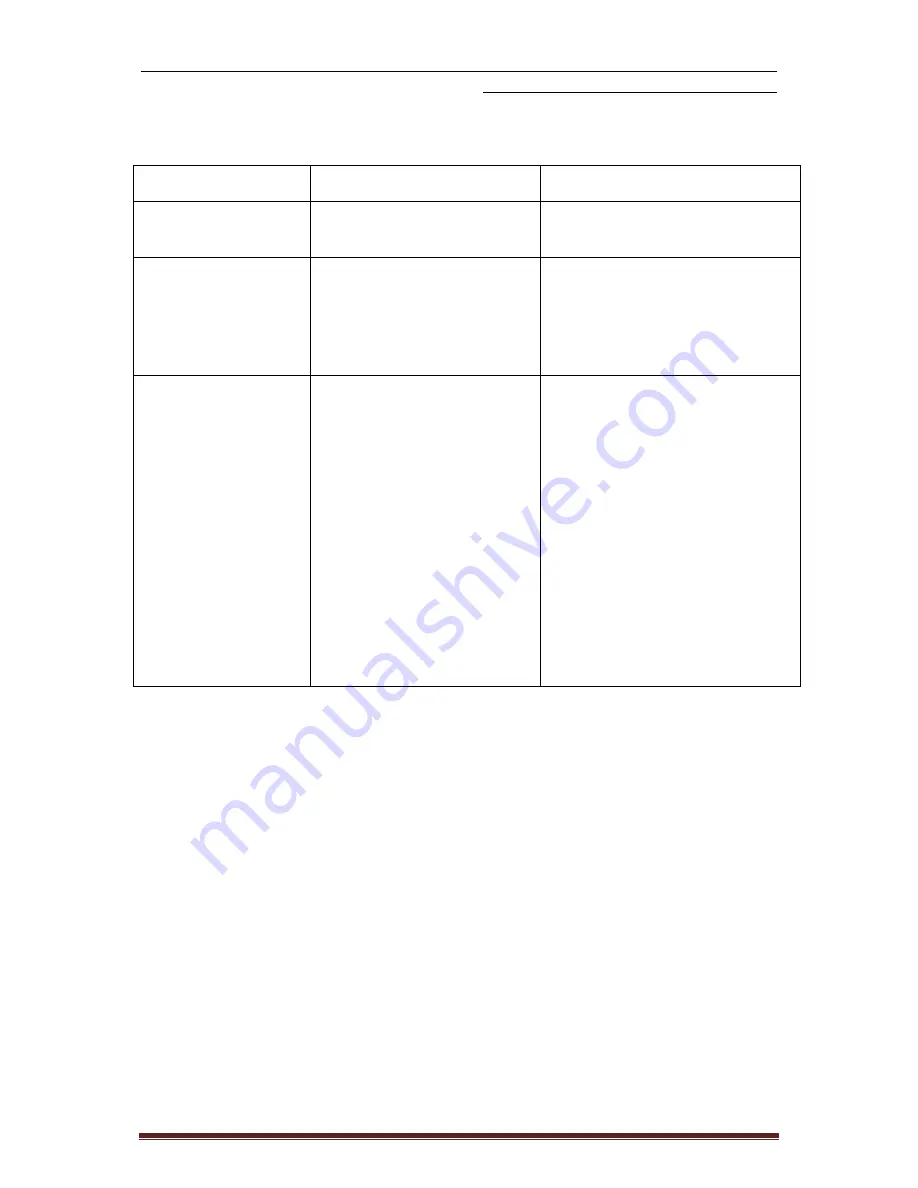

MANDREL SUPPORT ARM

PROBLEM/EFFECT

CAUSE

REMEDIES

Mandrel vibrates

Worn pivot bearings or shaft

on mandrel support arm.

Replace bearings and housings.

Sideways movement

between mandrel

support arm and

mandrel support

bearing.

Bearing loose in bearing

housings.

Loosen grub screws in bearings

and tap bearing outwards in

bearing housing - lock grub screws.

Replace housings and bearings.

Knife not slitting

through core and/or

knife cutting into

mandrel at one end of

machine.

Mandrel support not aligned

parallel to knife carriage.

•

Raise mandrel support.

•

Traverse carriage to extreme

right.

•

Adjust forward knife stop so

that the knife just touches

mandrel.

•

Traverse knife to the extreme

left and move knife forward to

mandrel.

•

Loosen grub screws locking

mandrel support arm to

bearings and move arm side-

ways so that knife touches the

mandrel fractionally harder than

at other end of machine (0.1mm

or 0.004”).

•

Lock grub screws and re-check.