JAVELIN MACHINERY (AUSTRALIA)

J800 /J900 OPERATION MANUAL

(incl. Troubleshooting Machine Problems)

JULY 2016

Page 22

MANDREL SLEEVE REPLACEMENT – ROTATING MANDREL

400m (15¾”) width (Tan) Sleeve Replacement

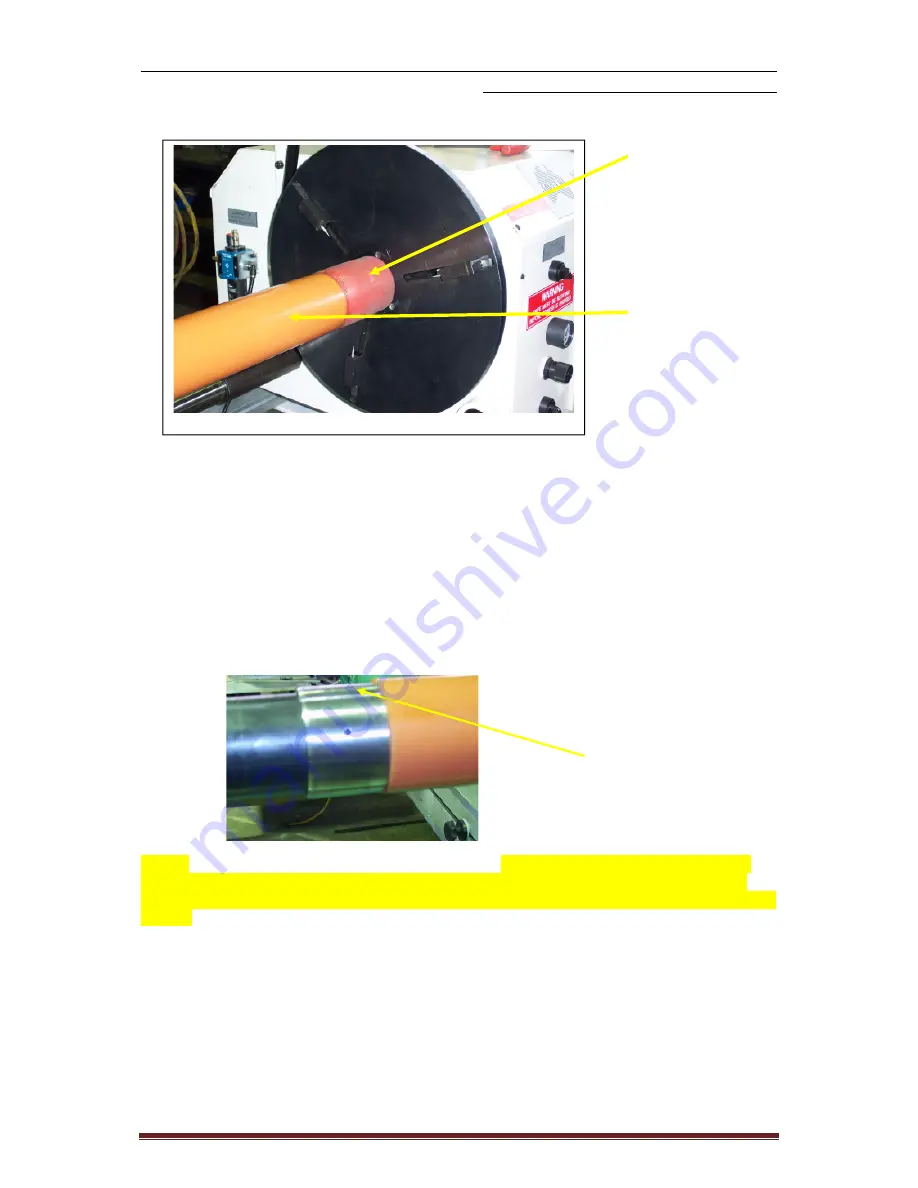

Retaining Collar

The worn area is cut out using a strong sharp knife and the good sections pushed up

the mandrel. A retaining collar (see

Figure 2

) is secured to the mandrel by tightening

two grub screws. This collar prevents the sleeves from separating.

The sleeves may appear to be a loose fit but when the retaining collar is pushed

against sleeve at load end of machine and grub screws are tightened the sleeves will

not move. Ensure that there is no clearance between collar and sleeve.

NOTE:

To maximize longevity of mandrel

sleeves ensure knife is set approximately 2 – 3mm away from OD of sleeve. When

operator pulls the cutting handle down the knife should then fractionally penetrate the

sleeve.

Mandrel Sleeve (Tan)

These sleeves cover steel

mandrel. The sleeves are easy

to slide on and remove enabling

small sections of worn sleeve to

be easily replaced.

Red Polyurethane Sleeve

Fits on the section of the mandrel

where the expansion jaws are

located. Because it is softer the

jaws will expand more fully and

therefore grip the I/D of the tape

Retaining Collar

Collar is secured to the

mandrel by tightening two

grub screws

Figure 2