User Manual Javo Rotofill

Version 2014-1-2

8

3.3

Options

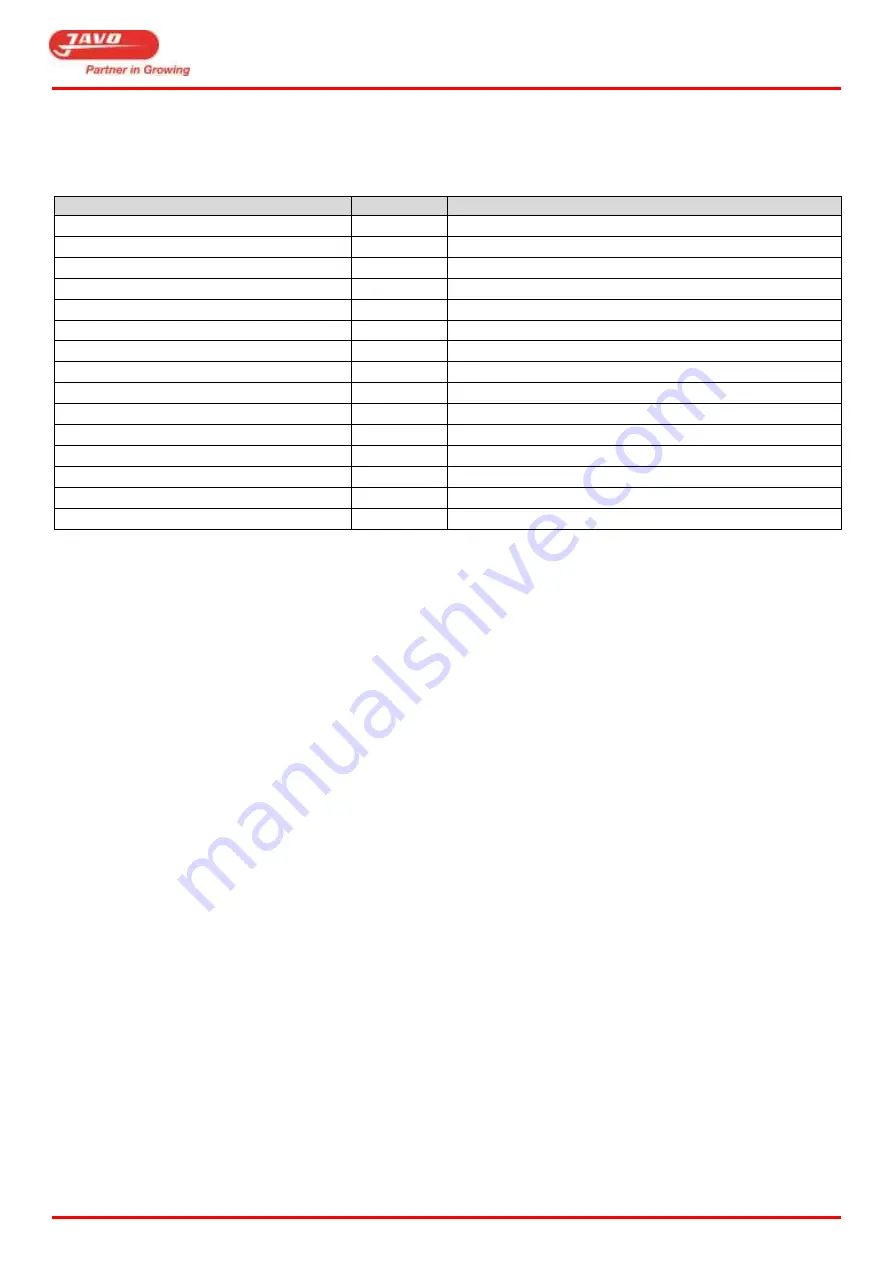

Depending on the intensity of use and customer requirements, this machine can be equipped with various options.

Contact your sales consultant.

Options

Code

Specifications

4 meter 5x1.5 cable incl. 16A plug

900965

Continuous socket

900966

Nonstandard

Switched Socket

1x 16A 5 pole

Substrate bin 1400x1400

212-264

753 Litre (t.b.v. original bin)

Tray guide 1 side

RFO1

2x bracket, 1x guide

Tray guide 2 sides

RFO2

4x bracket, 2x guide

Press on role

Instead of rotor above the tray

Height increasing set for tray throughput RFOT

Height transit 200mm (80mm minimum height)

Variator on conveyor

212-130 E

Minimum speed of 0 m/sec possible

Stainless steel slide plate

212-142

Air wheels incl. triangle back

SU1ZL

Wheels protrude outside the machine

Air wheels front

SU1L

Conveyor suspension

212-154

Is adjustable in width to 400mm

Substrate slide in substrate stock

212-270

Stainless steel substrate retour chain

212-001481 Stainless steel with 10 pushers

Options:

Transport conveyor

3.4

Operation

The process of the machine begins at the soil bin, which is filled with substrate. Substrate is transported with the

substrate conveyor to the elevator. The elevator transports substrate to the rotor.

The rotor divides substrate evenly over the full width of the tray, in the cells of the tray. An equal amount of

substrate is divided in all the tray cells.

A vibrator is mounted under the conveyor. As a result, the substrate in the tray is divided more evenly. The

remaining substrate is returned through the ground retour chain.

The filled tray is transported and passes a substrate slide. At the substrate slide, the excess substrate is removed

from the tray. The tray is then evenly leveled by the brush unit.

The machine is equipped with wheels, which makes the machine easy to move.

3.5

Machine workstations

This machine has two operator places; at the conveyor belt, both the inlet and the outlet on the side of the substrate

bin.