10

Turn on the unit and listen for any possible abnormalities, such as the blades rubbing against the

venturi. Make adjustments if necessary. If no problems are detected, slowly turn the flowmeter control

knob counter-clockwise until the desired output is achieved. The fluid level ball should move up and

down as adjustments are made.

If using an oscillator

, check the rotational movement and be SURE THE POWER CORD HAS ENOUGH

SLACK. If there is not enough, try re-mounting the GT 500 with the oscillator power cord falling in

line with its motor.

Note:

GT 500 can also be operated dry.

The volume of fog can be regulated by adjusting the

flowmeter.

Particle size is smaller at lower outputs, so it is

better to operate the fan at a lower output for a

longer period of time.

Flowmeters maintain a more reliable flow rate if

operated high on their flow scale.

If your desired output volume is close to the

bottom of the scale, it may be beneficial to

purchase a smaller flowmeter or install a 5

micron sediment filter.

At the base of the flowmeter is an in-line strainer

(Part #71) with a removable cap. Periodically check

inside and flush any sediment from the screen.

O

PERATION

BEFORE TESTING FAN MAKE SURE ALL OBJECTS ARE OUT OF THE

ROTATION PATH OF THE FAN BLADES. HIGH-SPEED WARNING. KEEP HANDS

CLEAR! MAKE SURE GUARDS ARE INSTALLED OR UNIT IS OUT OF REACH.

LISTEN FOR UNUSUAL NOISE OR VIBRATION.

CAUTION

BUMP START GT 500 and check for proper fan blade rotation (clockwise if looking at

front of unit). If incorrect, find rotation connection changes on the motor's electrical schematic.

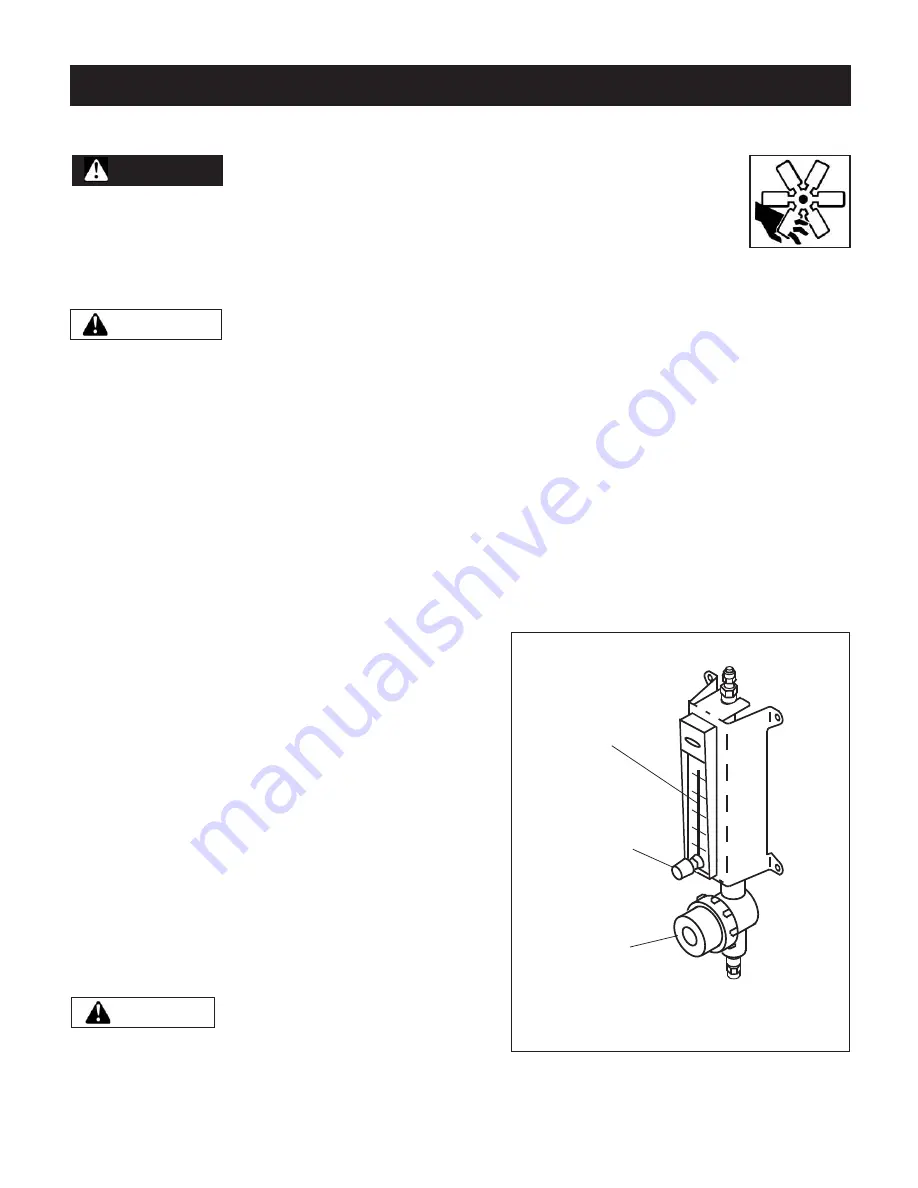

Flowmeter Control

NOTICE

CLOGGING OCCURS MORE

FREQUENTLY WHEN OPERATING AT

LOW FLOW RATES.

DANGER

F

LOWMETER

P

ANEL

Flowmeter's Flow

Control Knob

Flowmeter's

Scale

In-line

Strainer

www.JigglyGreenhouse.com | (800) 878-7829 | Sales@JigglyGreenhouse.com