TC-710 - INSTALLATION AND MAINTENANCE MANUAL

TC-710

www.jaypro.com / (800) 243-0533 / 976 Hartford Tpke, Waterford, CT 06385 USA

SUBJECT TO CHANGES IN DESIGN AND MANUFACTURING

COPYRIGHT 2018 JAYPRO SPORTS, LLC. ALL RIGHTS RESERVED

Rev D, Sheet 4 of 9

INNOVATION, PERFORMANCE AND COMMITMENT SINCE 1953

4. Assemble drive pipe as shown on the supplied pipe layout drawing. To connect

each section of drive pipe, a 19 3/4" long interior splice is supplied. Each splice

requires drilling 12 holes and installing 12 aluminum rivets. Refer to Figure 3.

*** IMPORTANT NOTE ***

All aluminum rivets used in assembling the drive pipe MUST be located away from the

roller cradle assemblies. Shift the roller cradle assemblies if necessary. Aluminum rivets

located within the roller cradles will create an uneven bearing surface on the roller

cradles and will cause damage to the curtain. Refer to Figure 4.

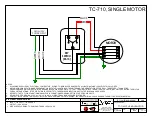

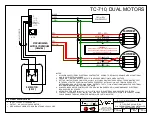

5. Assemble and insert motor

into the drive pipe using the motor

drive and crown. Refer to Figure 5.

FIGURE 3: DRIVE PIPE SPLICE DETAIL

FIGURE 4: SPLICE RIVET LOCATION

120

EQ. SPACED

3/16" ALUMINUM RIVET

12 PER SPLICE

LOCATE AS SHOWN

EQUAL GAP

19 3/4" INTERIOR SPLICE

2"

2"

6"

6"

DRIVE PIPE

SPLICE

7/32" DIA HOLES

12 PLACES EACH SPLICE

2" MINIMUM CLOSEST RIVET TO

ROLLER CRADLE ASSEMLY

DRIVE PIPE

SPLICE

DRIVE FOR

MOTOR

(HM6153)

TUBULAR MOTOR (HM6151)

CROWN FOR TUBULAR

MOTOR (HM6152)

DRIVE PIPE

MOTOR (HM6151)

DRIVE (HM6153)

CROWN (HM6152)

DRIVE PIPE

FIGURE 5: INSTALLATION OF DRIVE MOTOR