7

There are different models of protectors and

extractors as accessories.

The measurements of all the extractors and

protectors are given on page 27 of instructions

manual.

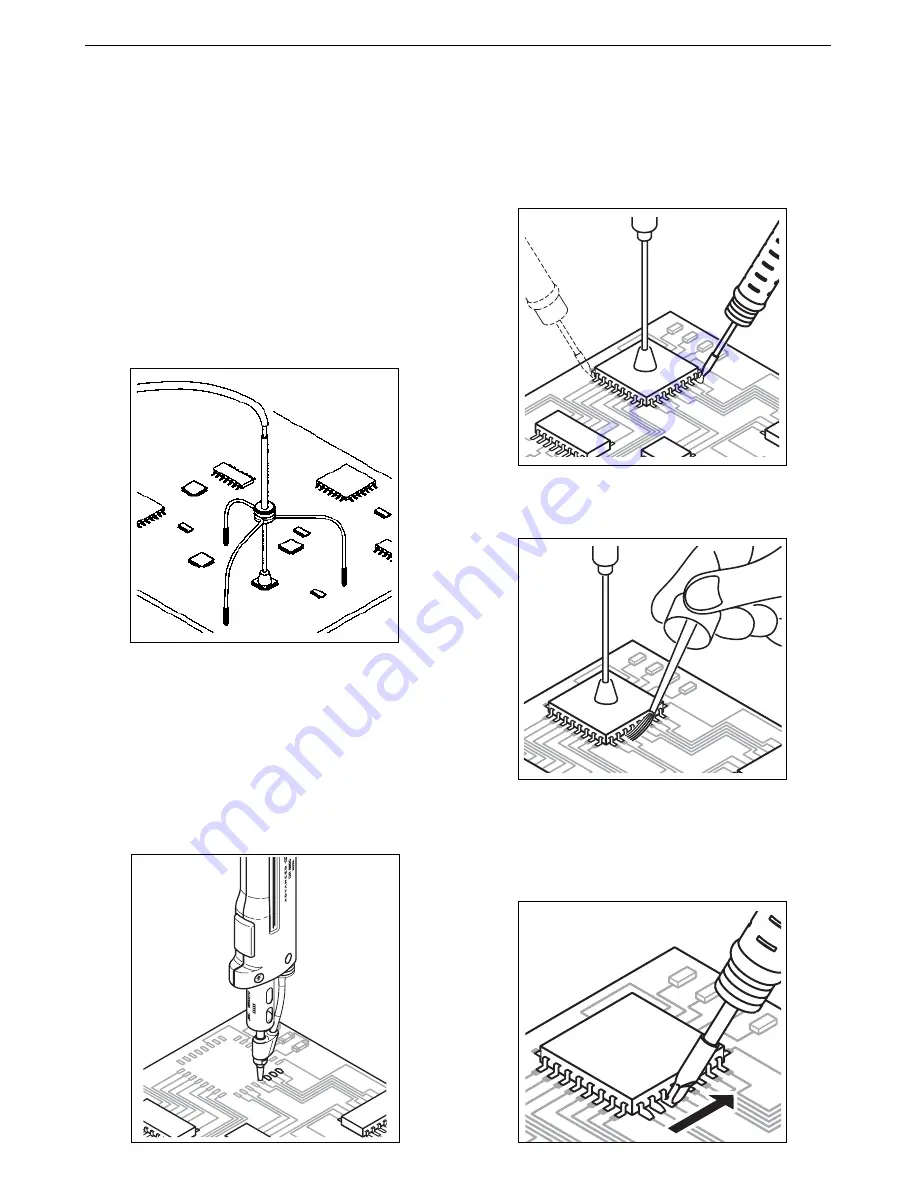

C) Tripod:

For small components for which an extractor

cannot be used, we recommend use of tripod 20

Ref. 0932050, as shown in the figure.

Use the tripod 40 Ref. 0932250 for larger integrated

circuits.

SOLDERING PROCEDURE

1 After desoldering the component, any solder

left on the printed circuit should be removed

with our

DR 5600

desoldering iron

ref. 5600000.

2 Place the component or printed circuit with

the

MP 2260

Pick & Place ref. 2260000.

3 When the component is correctly placed,

solder its pins.In the case of integrated circuits

of the Flat Pack type, first solder one pin of

every IC angle to fix it in place in the circuits.

4 Apply

FL 9582

flux

ref. 0046565

in pads and

leads.

5 Solder the remaining pins. For this we

recommend to use our soldering irons of the

Advanced series, which are available in two

different models:

Summary of Contents for AM 6500

Page 1: ...Instructions manual US Version 0781056 0405 AM 6500 REWORK STATION ...

Page 21: ...20 ELECTRIC WIRING DIAGRAM Valid from serial n 99751 ...

Page 22: ...21 ...

Page 23: ...22 ...

Page 24: ...23 ...

Page 25: ...24 ...

Page 26: ...25 ...

Page 27: ...26 ...