325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

19:29

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Language

Sta�on se�ngs

Tool se�ngs

Counters

Reset

Exit

Feeder se�ngs

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Tin reload process

Mode

Con�nuous

5.0mm/s

1.00mm

Off

None

Speed

Wire diameter

Feeder parameters lock

Backward

Back

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Tin reload process

Forward

Backward

Place the �n on the gears

and press:

Press ok to exit

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Program

Con�nuous

Discon�nuous

Mode

Back

0.5

mm/s

25%

75%

Power

Con�nuous

50%

19:29

Sel. Temp.

350

º

C

Ø 1.00 mm

Supplied: 0 mm

350

º

C

0.5

10.0

25%

75%

Power

Discon�nuous

50%

19:29

Sel. Temp.

350

º

C

Ø 1.00 mm

350

º

C

mm/s

mm

25%

75%

Power

50%

19:29

Sel. Temp.

350

º

C

350

º

C

3

2

1

Program #1

Ø 1.00 mm

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Tin reload process

Mode

Con�nuous

20.0mm/s

1.00mm

Off

5.0mm

Speed

Wire diameter

Feeder parameters lock

Backward

Back

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Feeder parameters lock

20.0mm/s

1.00mm

Off

5.0mm

Speed

Tin reload process

Wire diameter

Backward

Back

Mode

Con�nuous

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Feeder parameters lock

1.00mm

Off

2.0mm

Edit program

Programs loaded

Set default programs

Tin reload process

Wire diameter

Backward

Back

Mode

Program

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Edit program

Program #1

Length

Speed

3

2

1

mm

1.0

5.0

5.0

5.0

2.0

2.0

mm/s

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Edit program

Length

Speed

3

2

1

mm

None

None

None

None

2.0

2.5

mm/s

Program #4

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

19:29

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Language

Tool se�ngs

Counters

Reset

Exit

Feeder se�ngs

Sta�on se�ngs

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

English

Deutsch

Español

Italiano

Français

日本語

한국어

Português

Pусский

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Program version

8886732

Maximum temp

400

º

C

Off

200

º

C

On

º

C

mm

Minimum temp

Sound

PIN

Temp units

Length units

Sta�on reset

Back

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Temp adjust

0

º

C

Temp level set

Off

10min

0min

150

º

C

Sleep delay

Peripher.

Sleep temp

Hiberna�on delay

Back

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Plug hrs

28

Working hrs

Part

Tot

6

0

0

0

20

1

2

1

24

20

181

19

22786

118

Sleep hrs

Sleep cyc

Fed cyc

Fed mm

Hiber hrs

No tools hrs

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Feeder parameters lock

20.0mm/s

1.00mm

12.0mm

Off

5.0mm

Speed

Tin reload process

Length

Wire diameter

Backward

Back

Mode

Discon�nuous

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

Tin reload process

Mode

Con�nuous

5.0mm/s

1.00mm

Off

None

Speed

Wire diameter

Feeder parameters lock

Backward

Back

325

º

C

24.0

mm/s

25%

75%

Power

Con�nuous

50%

Sel. temp. 325

º

C

Ø 1.00 mm

Supplied: 12 mm

1.00mm

Upda�ng

Your sta�ons is being updated

No

Do you want to update firmware?

Yes

EARTH FUSE F1.25 A

USE ONLY WITH A 250 V FUSE

EARTH FUSE F1.25 A

Assembly with Solder Wire Perforation:

Inlet

Nozzle

Interm.

Nozzle

7

10

9

Counter

Wheel

Guide Tube

Set

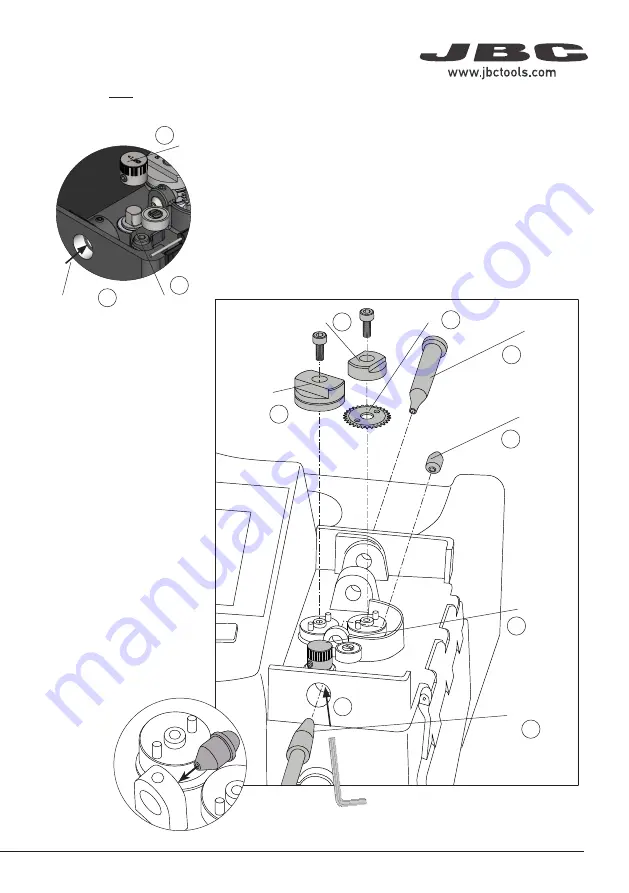

Insert the intermediate nozzle

(10) until its collar rests against

the housing and tighten its

screw.

Assemble the inlet nozzle (11).

Assemble the guide wheel*

(12) and tighten the screw.

Assemble the blade first (13),

then mount the blade clamp

(14) onto the same axis and

tighten the screw.

Caution:

handle the blade carefully to

avoid injury.

Finally insert the guide tube

set (15).

Counter

Wheel

Axis,

Flat Side

Allen Key

inserting here

8

9

7

11

Guide

Wheel *

12

13

Blade

Blade Clamp

* Guide wheel bears diameter marking.

Assemble the counter wheel (7). Make sure that its thread entry for the

set screw is aligned with the flat side of the axis (8). If not, the set screw

will protrude, which may cause difficulties for the wire transportation.

Inserting the Allen key through the front opening will make it easier to

tighten the screw (9).

14

15

SFR-B

GSFR

TRA

CLR

EXTR

ACCIÓN

22220

EXTR

ACCIÓN

26842

26843

EXTR

ACCIÓN

26846

26847

26848

EXTR

ACCIÓN

26844

VERMELL

NEGRE

GROC

VERMELL

BLAU

VERMELL

BLAU

BLAU

VERD

VERMELL

BLAU

VERD

VERMELL

NEGRE

GROC

VERMELL

BLAU

BLAU

VERD

Lor

em ipsum

** intermediate nozzle

assembly

9

40 mm

50 mm

60 mm

80 mm

100 mm

130 mm

130 mm

para manuales - color gris

200 mm

300 mm

Summary of Contents for GALE08V-A

Page 1: ...GALE Guide Kits for ALE250 INSTRUCTION MANUAL...

Page 4: ...GALE Guide Kits for ALE250 4...

Page 14: ...Notes 14...