WOB3500/MesDocuments/Corinne/Notices/WOB3500/Anglais

Section

Title - Topic

Section

Page

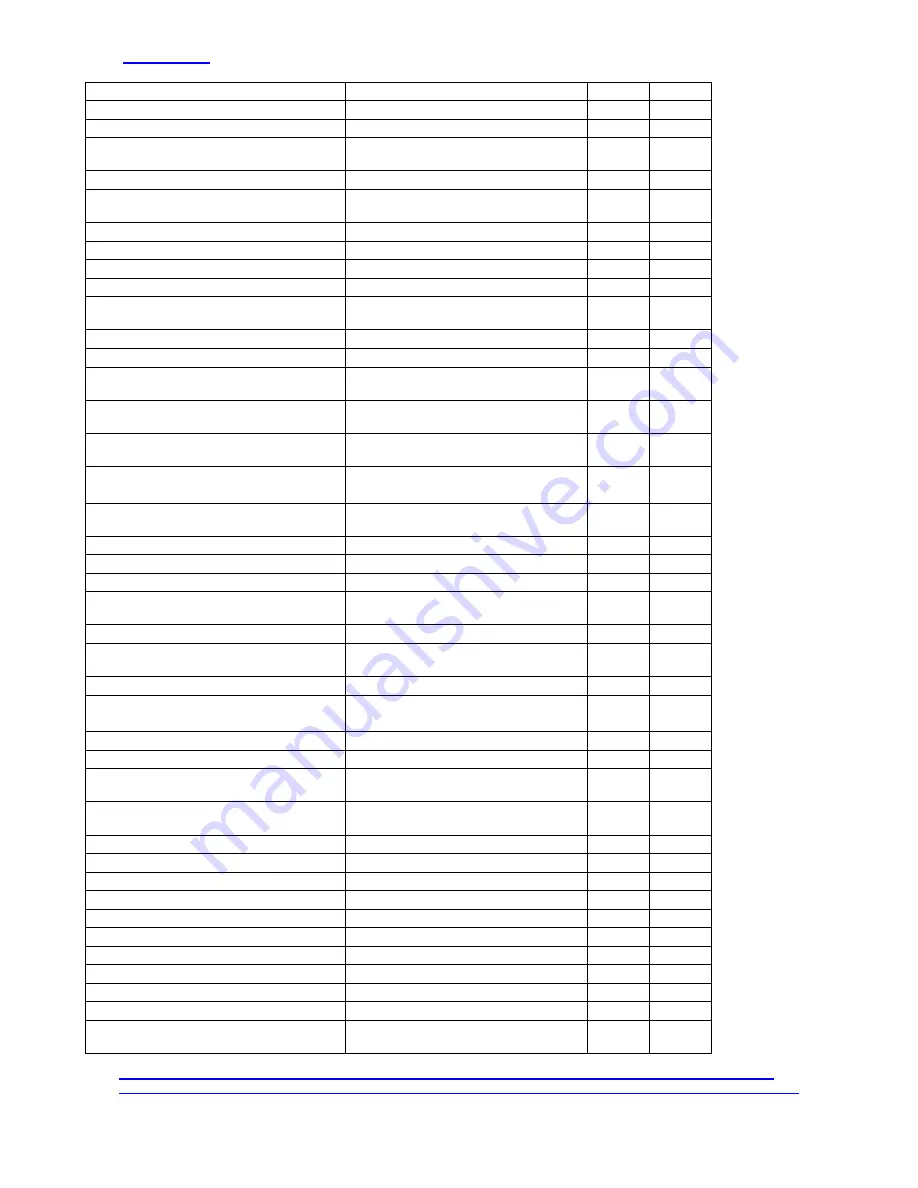

Contents

Introduction

Welcome

1

Contact addresses and telephone

numbers

2

1.Using your binding machine safely

Safety information

1

3

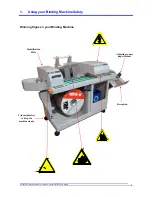

Safety warning signs on you binding

machine

1

4

Safety Instructions

1

5

Handle heavy equipment properly

1

6

Wear safe clothing

1

6

Protect children

1

6

Keep safety labels clean and in good

condition

1

7

Be prepared for emergencies

1

7

A note to all employers

1

7

Keep this manual with the binding

machine

1

8

If you need this manual in any other

language

1

8

Warning signs on and around your

binding machine

1

9

2.Installation of your binding

machine

Installation of your binding machine

2

10

Choosing a location for your binding

machine

2

10

Floor plan

2

10

Power points

2

10

Unpacking your binding machine

2

10

Unpacking your binding machine

continued

2

11

Warning

2

11

Unpacking your binding machine

continued

2

11

Technical data

2

12

3.How to select the correct size of

Wire-O

Wire sizes

3

13

Using the following formulae

3

13

Example

3

13

Table of recommended maximum book

thickness

3

14

Table of punched holes for each paper

size

3

14

4.Running your Binding Machine

Display opening : selection

4

15

Initialization

4

16

Work display (final)

4

16

Lifting and loading a Wire-O spool

4

17

Lifting and loading a Wire-O spool

4

18

Lifting and loading a Wire-O spool

4

19

Bring the wire to the spool unwinder

4

19

Wire feeding in the wheel

4

20

Wire adjustment

4

20

Wire modification

4

21

Reception adjustment

4

21

Contents