03 - Attachments, Couplings and Load Handling

00 - Attachments

00 - General

03 - 3

9813/4250-6

03 - 3

00 - General

......................................................

...........................................

..........................................................

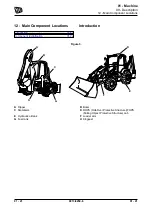

Introduction

A wide range of optional attachments are available

to increase the versatility of your machine. Only JCB

approved attachments are recommended for use

with your machine. Consult your JCB Distributor for

the full list of approved attachments available.

Some attachments are supplied complete with

instructions on safety, installing and removing,

operation and maintenance. Read and fully

understand the information before fitting, using and

servicing the attachment. If there is anything you do

not understand, ask your JCB Distributor.

Before using any attachment, read Working With

The Machine in the Operator Manual and consider

how the attachment is going to affect operational

safety. With the attachment installed, there may

be changes in the machine's centre of gravity or

overall dimensions. This could have an effect on, for

example, machine stability, the gradients on which it

is safe to operate or the safe distance from power

lines.

Practice using attachments off the job before working

with them for the first time.

JCB attachments are designed and manufactured

specifically to suit the machine's hydraulic system,

mounting arrangements and safe load requirements.

Attachments which are not designed for use with

this machine may cause damage and create safety

hazards for which JCB cannot be held responsible.

In addition the machine's warranty and any other

legislative compliance may be affected by the use of

non JCB approved attachments.

If your machine needs the hydraulic system adapting

to facilitate the use of auxiliary attachments, you

must consult your distributor. Only suitably qualified

personnel must reroute hydraulic hoses.

All optional attachments will have limits on their

operation. i.e. lifting capacity, speeds, hydraulic flow

rates, etc. Always check in the literature supplied

with the attachment or in the Specification section of

this manual. Some specification limits may also be

displayed on the attachments Data/Rating Plate.

Important: Do not operate or work with attachments

until the machine hydraulic oil has reached its normal

working temperature.

Summary of Contents for 3CXG

Page 2: ...9813 4250 6 Notes Find manuals at https best manuals com...

Page 4: ...Notes 9813 4250 6 Find manuals at https best manuals com...

Page 8: ...Notes 01 2 9813 4250 6 01 2 Find manuals at https best manuals com...

Page 22: ...Notes 01 16 9813 4250 6 01 16...

Page 26: ...Notes 01 20 9813 4250 6 01 20...

Page 32: ...Notes 01 26 9813 4250 6 01 26...

Page 36: ...Notes 9813 4250 6 2017 11 23...

Page 38: ...Notes 03 2 9813 4250 6 03 2...

Page 51: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com...