CAPTIVE SYSTEM

jcm

technologies

10

2.

Detection principles

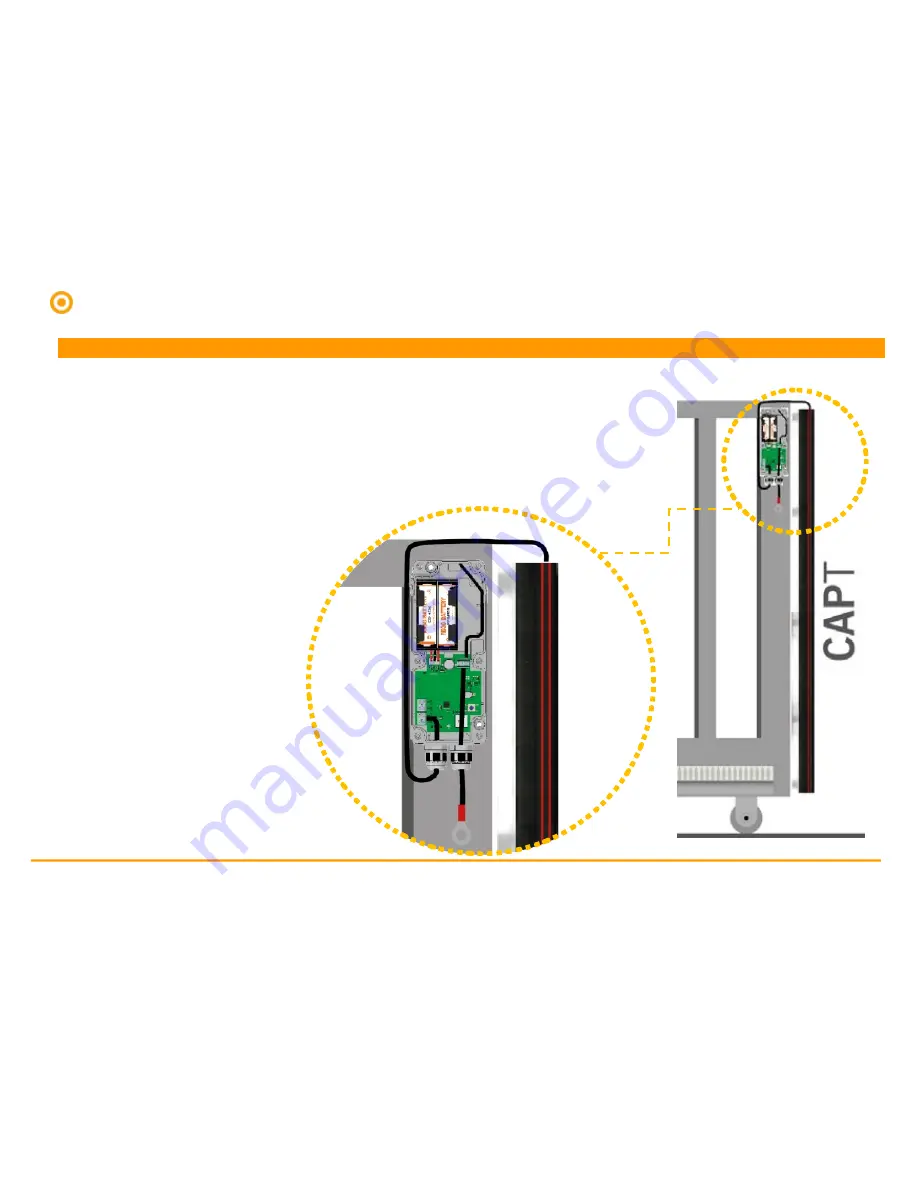

CAPT detects objects near the safety edge of the gate by detecting variations between conductive part of the gate and

conductive parts of the safety edge.

For that reason CAPT has a cable to connect GND to the metal part of the gate.

It is very important for the proper working of the NO TOUCH detection that the ground

reference is properly connected.

The measurement is going to

depend on:

•

Size of the conductive

part of the object.

•

Distance from the

object to the edge of

the gate.

Maximum safety edge length=

2.5m.