June, 2014

Part No. 960-100932R_Rev. A

© 2014, JCM American, Corporation

Part No. 960-100932R_Rev. A

© 2014, JCM American, Corporation

1 4

3

PREVENTIVE MAINTENANCE SCHEDULE

The iVIZION Banknote Validator will perform at optimal levels when regularly-

scheduled maintenance is performed. The recommended Preventive Mainte-

nance Schedule should be followed based on time periods or acceptance cycles.

The acceptance cycle can be determined by adding the number of Banknotes

accepted to the number of Tickets accepted for a total estimate of acceptance

cycles.

MONTHLY OR 12,000 CYCLES

Every Month or 12,000 Cycles, the following procedures should be performed at

the Machine (approximate time for completion: 30-60 seconds):

INSPECTION

1. Remove the iVIZION Validator from the Machine, and place it on a suitable

work surface.

2. Perform a visual inspection of the entire iVIZION Unit. Look for any broken or

damaged parts that need to be repaired or replaced.

Table 1

Monthly or 12,000 Cycles

Component

Procedure Description (Details follow this table)

Validator Head

Clean all the Sensor Lenses in the Validator Head (refer to

Figure 2

- iVIZION Validator Head (Yellow Area).

Transport

Clean all the Sensor Lenses in the Transport Unit (refer to

Figures 3 and 8

- iVIZION Transport Unit (Yellow Areas).

Transport

Clean the Transport Feed-In Sensor Lenses (refer to

Figure 3

- iVIZION Transport Unit - Feed-In Sensor).

Cash Box

Clean all the Sensor Lenses in the Cash Box (refer to

Figure

4

- iVIZION Cash Box (Yellow Area).

Reinstall and verify proper operation.

NOTE: The actual Maintenance Schedule may vary, due to environmental

conditions and/or usage levels.

CASH BOX PREVENTIVE MAINTENANCE

1. Open the Cash Box and use compressed air or moisture-free low pressure (LP)

air to blow out any dust or debris from inside the Cash Box.

2. Use a damp, lint-free cloth to wipe away any dust, dirt or stains from the Cash

Box Gears.

3. Using a Technician’s Cleaning Brush (JCM P/N 501-000097R), clean any

debris built up on the Cash Box Gears.

4. Using a clean, damp, lint-free cloth, clean the Cash Box Sensors (refer to

Figure

10,

yellow areas).

5. Use a dry, clean, lint-free cloth to wipe away any dirt, debris and moisture from

the Cash Box.

NOTE: Cash Box Preventive Maintenance should be performed annually

or as needed. Remove the Cash Box from the Game, and then

perform the procedure listed below.

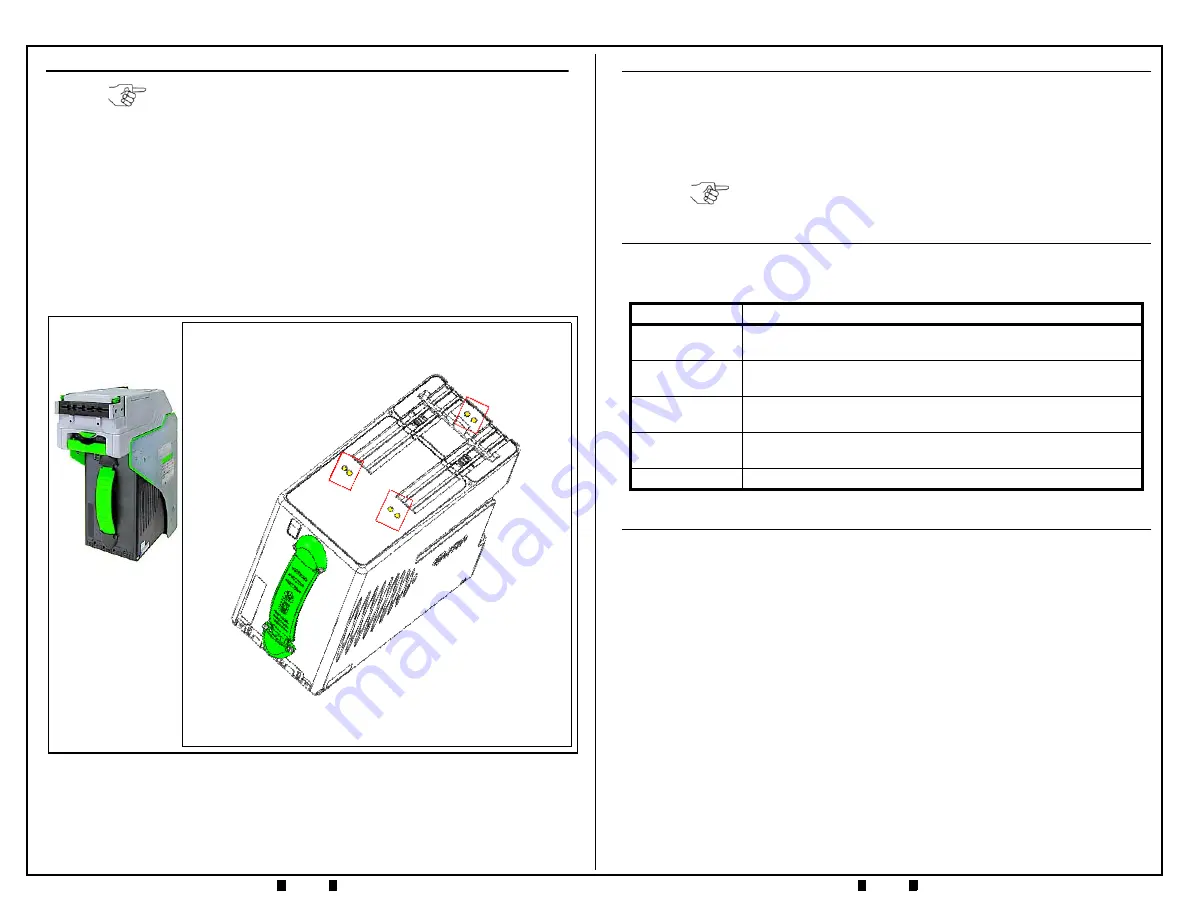

Figure 10

iVIZION Unit and Cash Box

Typical iVIZION Unit

(fully assembled)