June, 2014

Part No. 960-100932R_Rev. A

© 2014, JCM American, Corporation

Part No. 960-100932R_Rev. A

© 2014, JCM American, Corporation

8

9

CLEANING THE VALIDATOR HEAD (6 MONTHS/72,000 CYCLES)

1. Perform the Monthly Validator Head Cleaning Procedures (refer to Page 4).

2. Inspect the Drive Belts in the Validator Head (refer to

Figure

5

, orange areas).

2. Inspect the Imaging and Optical Sensor Lenses on the Validator Head (refer to

Figure

5

, yellow areas) for scratches, chips, cracks or discoloration.

3. Using canned, compressed air or a clean, moisture-free source of low pressure

(LP) air, blow out any dust, debris, or paper fibers from the Validator Head.

4. Clean the Rollers in the Validator Head using a Technician’s Cleaning Brush

(JCM P/N 501-000097R) to remove the dirt and any build-up.

5. Clean the Drive Belts in the Validator Head using a clean cloth dampened with

cleaning solution. The Drive Belts in the iVIZION Validator Head can easily be

moved by hand, to allow cleaning of the entire belt.

NOTE: If the Drive Belts are heavily frayed, worn out, or damaged, the belts

should be replaced.

Minor fraying along the left and right edges of the drive belts may

result in “Belt Strings” extending out from the sides of the belts. These

strings can be snipped away with a small pair of scissors. Drive belts

do not need to be replaced if only minor fraying is evident.

NOTE: If a lens has any of these conditions, the lens should be replaced.

NOTE: Use a wood or plastic wand to apply pressure to the side of a Roller, to

keep it from turning during cleaning.

Be careful not to scratch the Rollers! Scratched Rollers will collect dirt

faster, and may require more frequent cleaning.

Figure 5

iVIZION Validator Head

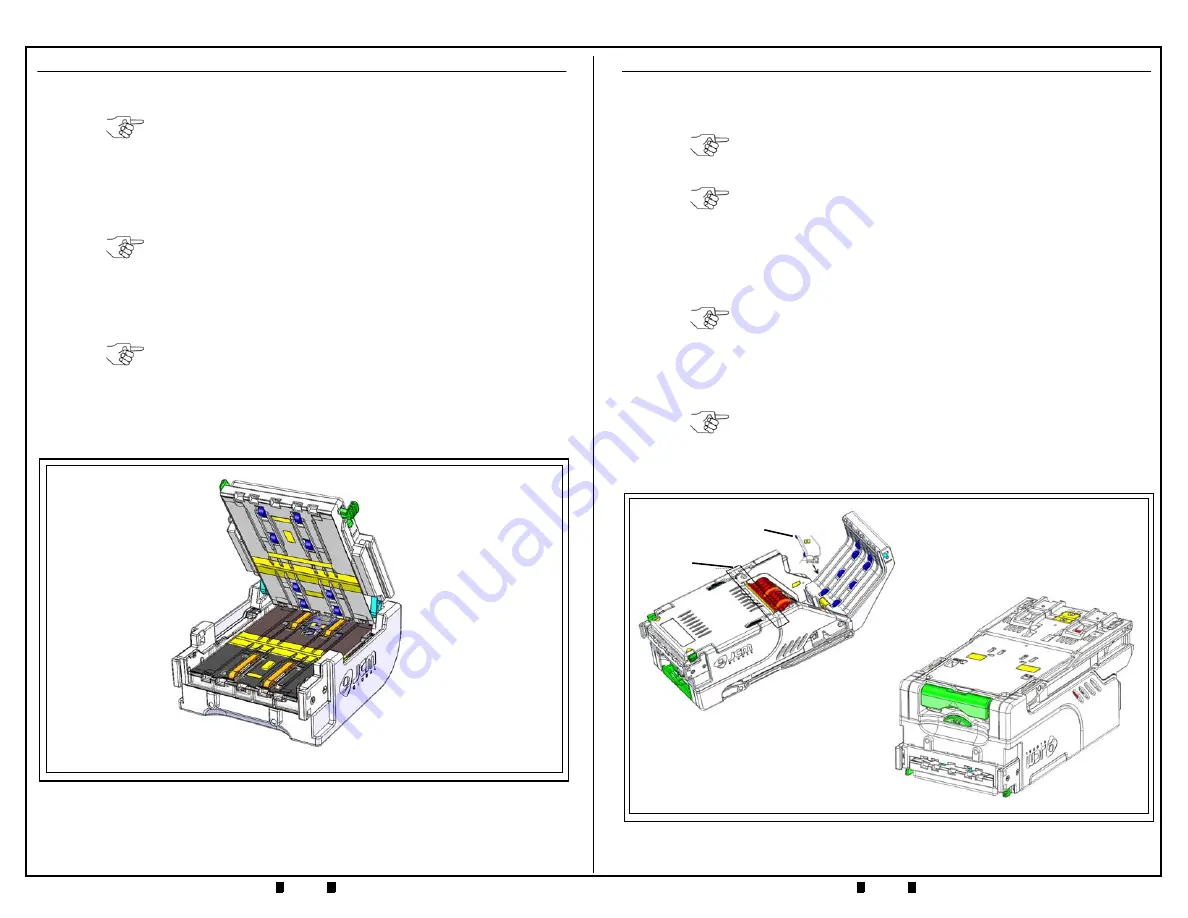

CLEANING THE TRANSPORT (6 MONTHS/72,000 CYCLES)

1. Perform the Monthly Transport Cleaning Procedures (refer to Page 5).

2. Inspect the Optical Sensor Lenses on the Transport Unit (refer to

Figure

6

, yellow

areas) for scratches, chips, cracks or discoloration.

3. Inspect the Drive Belts in the Transport Unit (refer to

Figure

6

, orange areas).

4. Using canned, compressed air or a clean, moisture-free source of low pressure

(LP) air, blow out any dust, debris, or paper fibers from the Transport Unit.

5. Use a clean, lint-free Micro-Fiber cloth (dampened with cleaning solution) to

wipe off the Rollers in the Transport Unit (refer to

Figure

6

, blue areas).

6. Use a clean, lint-free Micro-Fiber cloth (dampened with cleaning solution) to

wipe off the Belts in the Transport Unit (refer to

Figure

6

, orange areas).

.

NOTE: If a lens has any of these conditions, the lens should be replaced.

NOTE: If the Drive Belts are heavily frayed, worn out, or damaged, the belts

should be replaced.

Minor fraying along the left and right edges of the drive belts may

result in “Belt Strings” extending out from the sides of the belts. These

strings can be snipped away with a small pair of scissors. Drive belts

do not need to be replaced if only minor fraying is evident.

NOTE: Be sure to blow out the Anti-Stringing Mechanism and the grooved

channel in front of it (refer to

Figure

6

).

NOTE: If necessary, use a Technician’s Cleaning Brush (JCM P/N 501-

000097R) to remove residue build-up from the Belts in the Transport

Unit. The Drive Belts can easily be moved by hand, in order to clean

the entire belt.

Figure 6

iVIZION Head and Transport Unit/Inverted Unit

Feed-In

Sensor

Stacker

Sensor Lens