6

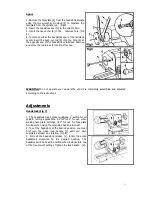

Spurs

1. Remove the faceplate [1] from the headstock spindle

using the two wrenches provided [2] to separate the

faceplate from the spindle nut. (Fig5)

2. Insert the headstock spur [3] in the spindle hole.

3. Insert the live center [4] in the tailstock hole. (Fig

6)

4. To remove either the headstock spur or the tailstock

center insert the push-out rod [5] into the hole [6] at

the opposite end of the headstock or tailstock. Remove

and store the rod in a safe location after use.

WARNING!

Do not operate your wood lathe until it is completely assembled and adjusted

according to the instructions.

Adjustments

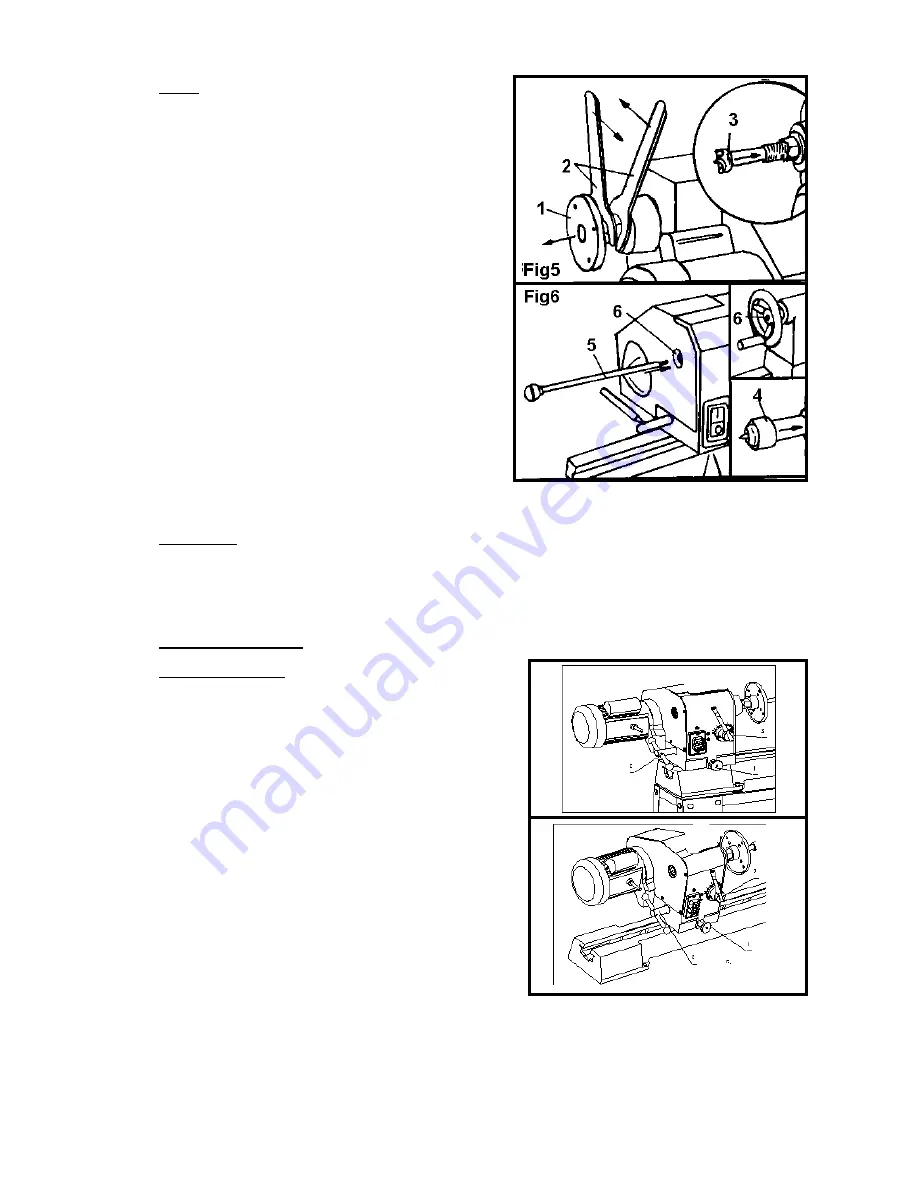

Headstock (Fig 7)

1. The headstock has 5 preset positions, 0

0

setting for all

spindle turning applications, 60

0

/90

0

/120

0

for use when

making face plate turnings, 180

0

for use for face plate

turnings when using the extension bed and tool rest.

2. To set the headstock at the desired position, you must

first turn the head lock handle [2] until you have

completed at least one rotation. (Fig 8)

3. Pull out the headstock release [1], rotate the entire

headstock clockwise to the desired position. The

headstock will be fixed in position when it clocks into one

of the five pre-set settings. Tighten the lock handle

[2].