21

3).

Various advice.

- Occasionally check the tightness of the 3 assembly bolts of the gearbox output shaft

coupling sleeves. These bolts ensure the safety of the spreader’s mechanical parts and the

tractor PTO, by breaking off if the rotors or moving floor are jammed.

- After 10 hours of use check the wheel locking system.

- Check the tension of the spreading device’s drive chain.

- The tension of the moving floor’s chains should be moderate.

4).

Chains.

1-

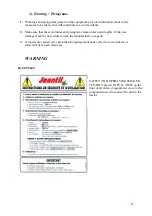

Follow instructions on the stickers placed at the front of the spreader for moving

floor chains (see page 11).

2-

The

tension

of the chains should be

moderate

. CONTROL THE CHAIN

ALIGNMENT.

3-

During the running in period, the chains may stretch significantly,

tighten again if

necessary

.

4-

When the tensioners are at their maximum for adjusting chain,

cut two links

and

tighten again.

5-

Check the

tightness of attachment screws

on the moving floor connector bars,

especially during the first hours of operation.

6-

Check the

state of the drive sprockets

for the moving floor chains. As soon as they

are damaged change them to avoid any risk of derailment.

5).

Wheels.

1-

Fixing: Check tightness of wheels regularly and after having used the equipment for

10

hours

.

2-

Inflation: Follow the instructions on the stickers and regularly check pressure.

Check the pressure of the tyres when the equipment is delivered. The pressure should

then be checked after every 10 hours of work. When checking the pressure, control the tyre’s

tread and wall. A damaged tyre should be immediately changed.

Warning! Changing or inflating a tyre can be dangerous!

Only use safe and adapted equipment or call in a professional.