22

3-

Braking.

Regularly check:

The surface condition of cables

The tightness of the cable clamps

The cable tension

The thickness of the drum brake lining

6).

Hydraulic hoses.

1-

See page 15 (Section: Maintenance and repair).

2-

Regularly check the state of the hydraulic hoses, especially sections in contact with

the equipment.

3-

Control that there are no leaks from the hydraulic connectors.

4-

Retighten the hydraulic connectors if required after the first few hours of operation.

7).

Speed of moving floor’s hydraulic motor.

(Included in the hydraulic moving floor option)

1-

The speed of the moving floor’s hydraulic motor is electrically controlled. The

first

electric button

marked

0 (- +)

located at the bottom of the electric control unit,

enables to adjust the speed of the moving floor depending on the load in the body

and in certain cases of certain difficult products: (ex: compact manure, etc.).

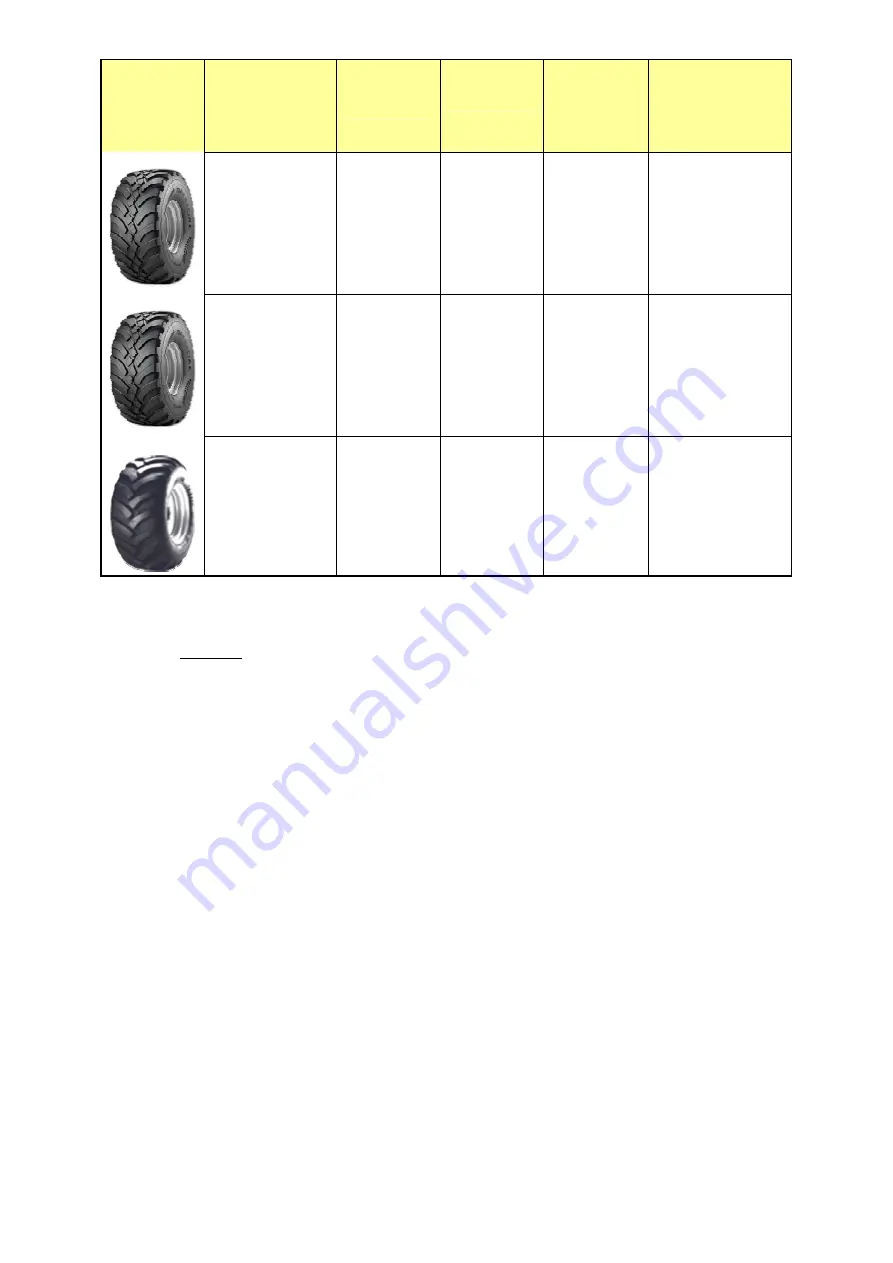

Profile

Dimensions

Diameter

(unloaded)

Tyre width

(unloaded)

Load per

wheel in kg

(mini –

maxi)

Inflation

pressure in bars

(40km/h)

mini - maxi

600/55R 26,5

(Standard)

1,34 m

0,63 m

2495 - 7100

0,8 - 4

680/55R 26.5

(Option for

Tandem / Bogie

/ Tridem)

1,4 m

0,67m

2995 - 6900

0,8 – 3,2

600/60 X 26.5

(Option for

Tandem &

Bogie)

1,5 m

0.60m

1570 - 3650

0,5 – 2,4