25

2-

If there are foreign matters, remove them before starting the spreader again.

3-

Be extremely careful

(see safety section).

9).

Hydraulic safety valves.

1-

All distributors are equipped with a hydraulic safety valve, set at

180 bars,

located

at the pressure inlet of the distributor unit.

2-

To check the valve calibration, connect a pressure gauge in parallel on the pressure

line:

a-

With hydraulic door:

- activate the dual-acting cylinders to limit,

- read the set pressure.

b-

With moving floor or shredder hydraulic motor:

- block the return port of the forward running motor,

- activate the distributor component of the forward running moving floor,

- read the set pressure.

3-

To calibrate or decalibrate, screw or unscrew the valve’s adjusting screw, and

control with pressure gauge.

10).

Door safety valve.

1-

Valve N°

825 246

fitted on the lower port (piston side) of one of the hydraulic door

cylinders.

2-

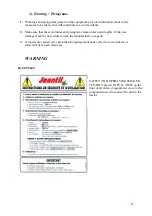

Safety for any maintenance or repair on or inside the spreader (see safety

instructions).

3-

Should be completely open when operating and completely closed for any

maintenance or repair on or inside the spreader (see sticker page 13).

4-

Check at least once a year the mechanical functioning of the valve by operating the

lever

2 to 3 times

without using the hydraulic distributor functions.

11).

Short period uses.

1-

The equipment should be very thoroughly cleaned and placed in a clean and dry

place.

2-

Entirely grease the parts described in the manual’s lubrication diagram.

3-

Cover the equipment with a tarpaulin.

10.

Start-up and operation.

1).

Important information.