USER MANUAL

JEFCIND200L-4.0

200L

BELT DRIVEN AIR COMPRESSOR

•

4HP

•

10Bar

•

230V

~

50Hz

USER MANUAL

JEFCIND200L-4.0

200L

BELT DRIVEN AIR COMPRESSOR

•

4HP

•

10Bar

•

230V

~

50Hz

www.jeffersontools.com

www.jeffersontools.com

4

5

•

200L

Belt-driven compressor suitable for professional workshops

•

Fitted with a heavy duty

single-phase

4HP

motor

•

Heavy-duty cylinders with alloy heads for improved heat dissipation

•

Pressure regulator with moisture trap

•

Fitted with 4x anti-vibration feet

•

Drive guards offer protection to the fly-wheel and belt assembly

•

Powder-coated tank

•

Twin pressure gauges showing tank and working pressure

•

Welded tank fully-compliant with the latest European manufacturing & safety standards

SPECIFICATIONS

JEFCIND200L-4.0

Tank Capacity:

200L

Power:

4.0HP / 3.0kW

Input Voltage ~ Frequency:

230V ~ 50Hz / 16A

Maximum Pressure:

10bar (145psi)

Pump Speed:

945rpm

Cylinders:

3

Air Displacement:

15.9 cfm (452 L/min)

Free Air Delivery:

9.4 cfm (266 L/min)

Guaranteed Sound Power:

96 dB LWA

Weight:

NW: 146kg / GW: 182kg

Dimensions:

1365 x 477 x 1033mm

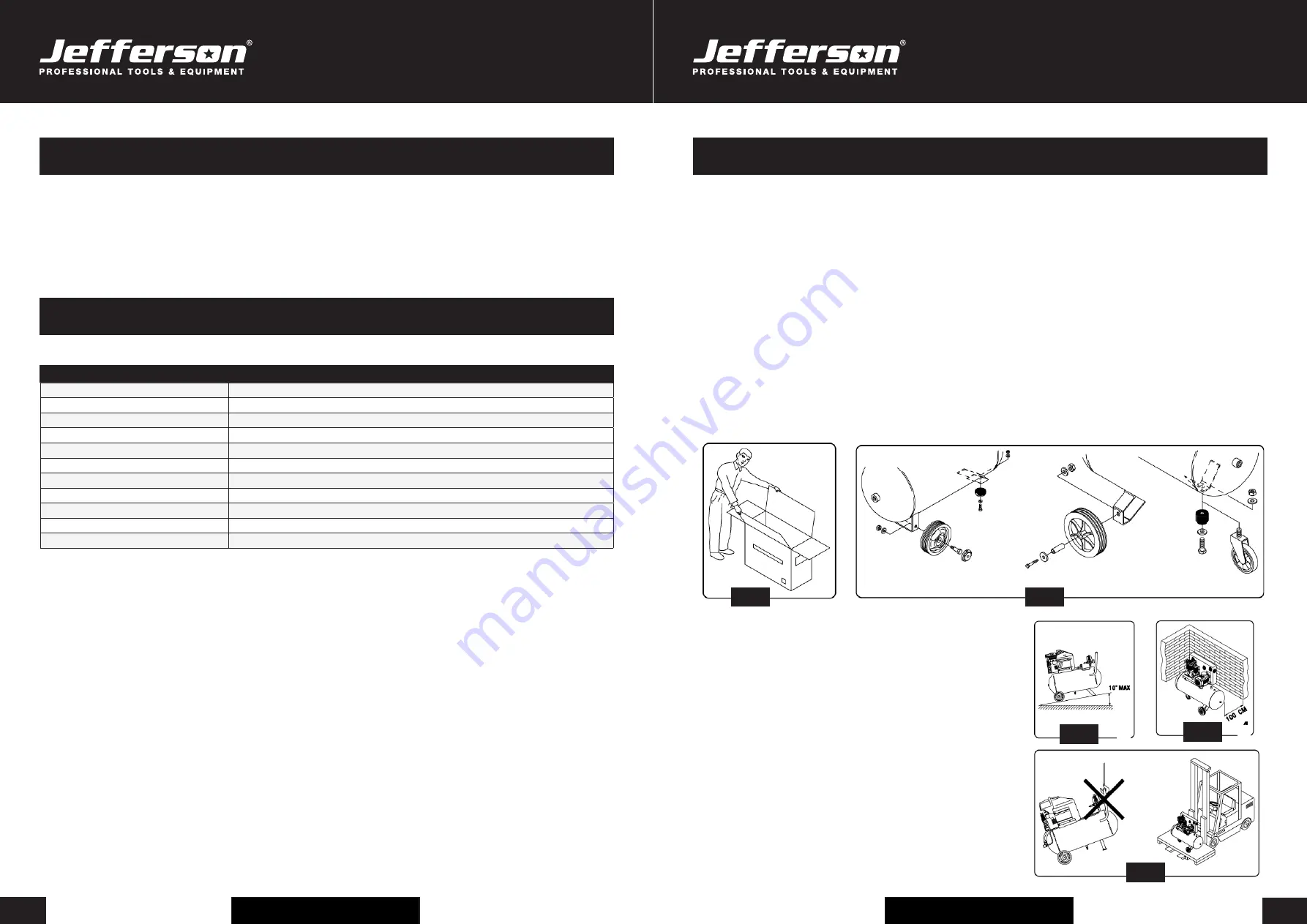

INTRODUCTION

Upon receipt of the compressor, ensure all components are present and have remained undamaged in transit..Retain the packing materials and

packaging in case future transportation of the compressor is necessary. We recommend that the packaging is kept, at least within the period of

the guarantee (

Fig.1

).

WHEELS AND ANTI-VIBRATION FOOT

Pass the 15mm bolt through the wheel, the compressor's frame and secure with the 15mm nut. Locate the wheel onto the axle and secure in

place with the internal self locking washer (single use only) (

Fig.2

).

AIR FILTER

If not already fitted, remove the transit bung from the top of the head and screw the air filter assembly into position.

OIL BREATHER

•

For transportation purposes the oil breather is supplied in a separate bag.

•

Read the caution plate and take off the plastic bung from the crankcase, add oil and then assembly the oil breather.

•

The plastic bung should be retained for future use should it be necessary to transport the unit.

WARNING:

Never operate the compressor with only the plastic transportation bung fitted. Under normal use internal pressure can expel the bung along with

oil from the head, possibly leading to damage.

PLEASE NOTE THE FOLLOWING PHOTOGRAPHS & INSTRUCTIONS ARE FOR REFERENCE ONLY AND MAY DIFFER FOR YOUR

COMPRESSOR MODEL. PLEASE CONTACT JEFFERSON TOOLS IF YOU NEED ANY ADVICE ON THE ASSEMBLY PROCEDURE.

Position the compressor on a flat surface or with a maximum permissible

inclination of 10° (

Fig.3

), in a well aired place, protected against atmospheric

agents and not in a place subject to explosion hazard.

If the surface is inclined and smooth, check if the compressor moves while in

operation – if it does, secure the wheels with two wedges.

To ensure good ventilation and efficient cooling, the compressor’s belt guard must

be at least 100cm from any wall (

Fig. 4)

.

Ensure that the compressor is transported correctly, do not overturn it or lift it with

hooks or ropes (

Fig. 5

)

After removing the packing materials, check to ensure the product is in perfect

condition and that there are no damaged parts from transit. If in doubt, do not use

the product and notify your Jefferson Dealer.

The packaging materials (cardboard, plastic bags, polystyrene, etc), must be

disposed of in an appropriate manner and recycled where possible. These

materials must not be left within the reach of children as they are potential

sources of danger.

UNPACKING & ASSEMBLY

Fig.3

Fig.4

Fig.2

Fig.1

Fig.5