USER MANUAL

JEFBG6 • JEFBG8

INDUSTRIAL

BENCH GRINDER

www.jeffersontools.com

4

•

Never place your hands, fingers or other body parts near the moving parts during operation. Ensure that the equipment is isolated from the

power supply and all switches in the

OFF

position before carrying out maintenance, repairs or adjustments.

•

Never operate this equipment without all guards or safety features in place and in proper working order. If maintenance or servicing requires

the removal of a guard or safety features, be sure to replace the guards or safety features before resuming operation.

•

When not in use, the grinder should be stored in dry place. Keep out of reach of children. Keep children and animals away from the work

area.

•

Clear all work areas of unnecessary tools, debris, furniture etc. prior to use. Cluttered work areas can lead to injuries.

•

Do not wear loose clothing or jewellery when operating this equipment. They can be caught in moving parts. Wear protective hair covering to

contain long hair.

•

Do not operate this equipment when you are tired or if you are under the influence of alcohol, drugs or medication that makes you drowsy.

•

Keep all screws, bolts, and plates tightly mounted. Check regularly.

•

Always contact an authorized service centre for advice on any repairs. Unauthorized modification may not only impair the equipment

performance but may also result in accident or injury to repair personnel who do not have the required knowledge and technical expertise to

perform the repair operations correctly.

•

Do not operate in the vicinity of flammable liquids, gases or solids.

•

Some dusts created by the grinding process are harmful or toxic. To risk exposure always work in a well-ventilated area wearing suitable

respiratory protection.

OPERATION GUIDE

Before Use:

Check inspect the equipment for damage and that it is safe to use before

connecting it to the power supply:

•

Ensure that the workpiece is free from oil, grease, paint and other substances

that might clog the grinding wheels

•

Ensure that the grinding wheels are kept clean to ensure safe and optimal

use.

•

Check that the tool rests are securely fixed and set at a maximum of

2mm

from the grinding stone.

•

Check that eye shields are in good condition, are secure and that you can see

through them clearly.

•

Turn the grinding stones by hand and check for any damage. Check they do

not touch the tool rests and are correctly aligned.

•

If any of the above checks fail, replace, repair, or adjust as necessary before

starting the grinder.

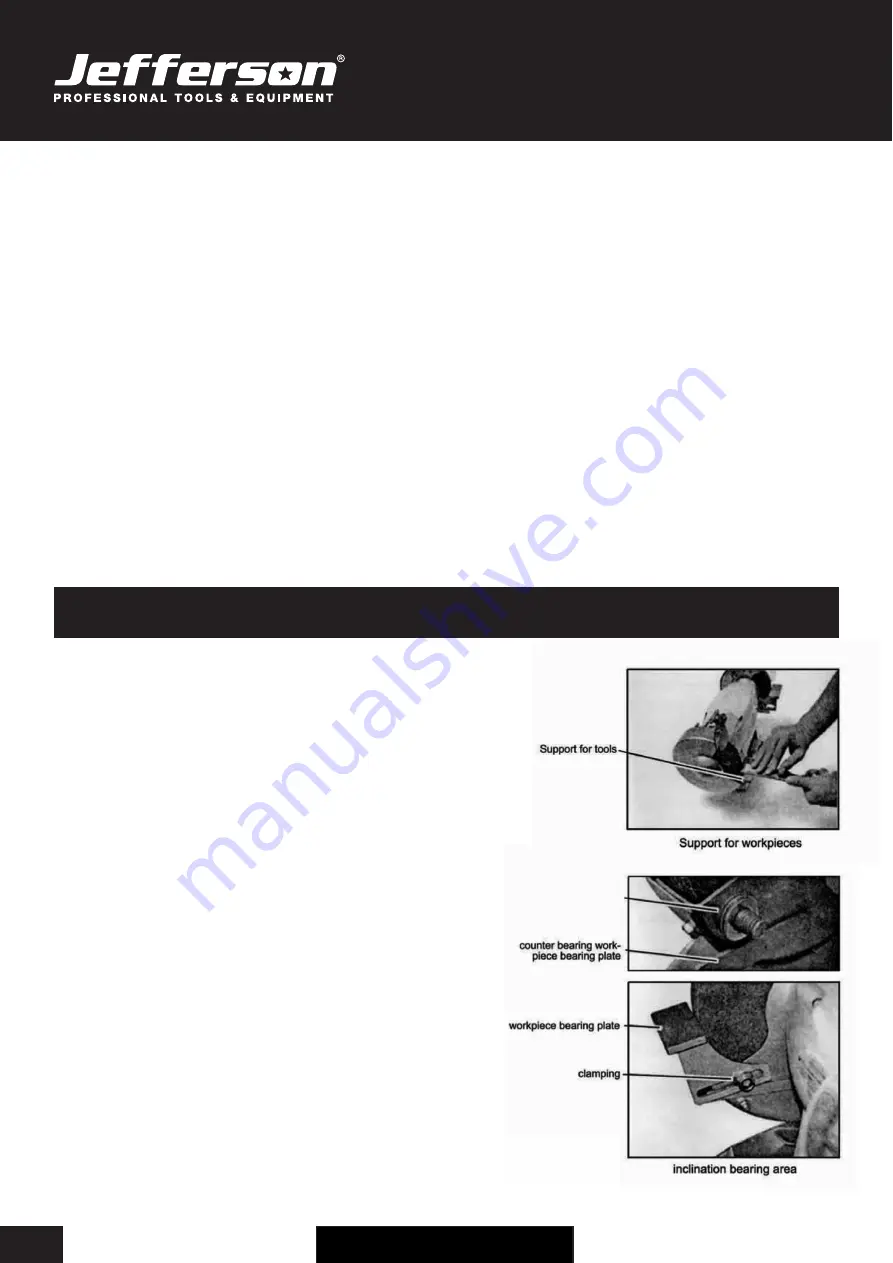

Using The Grinder:

•

Plug grinder into the mains power supply. Place the eye shield in its

appropriate safety location.

•

Switch the grinder on, and bring the work piece slowly into contact with the

spinning stone, or wire wheel.

•

When you have completed your task, unplug the grinder from the mains

power supply, and clean the machine ready for next use

Grinding Stones:

Grinding stones should only be assembled by a person holding a grinding wheel

certificate. There are generally two grades of grinding stone: fine stones are

preferred for hard materials and coarse stones for soft materials.

When grinding, should surface of the stone become “loaded” (coated with

particles of the material being ground) it is probably the wrong grade of stone for

the job. Contact your Jefferson Dealer for advice if required.