USER MANUAL

JEFC050L08B Series

50L

AIR COMPRESSOR

•

2HP

•

8Bar

•

Direct Drive

www.jeffersontools.com

10

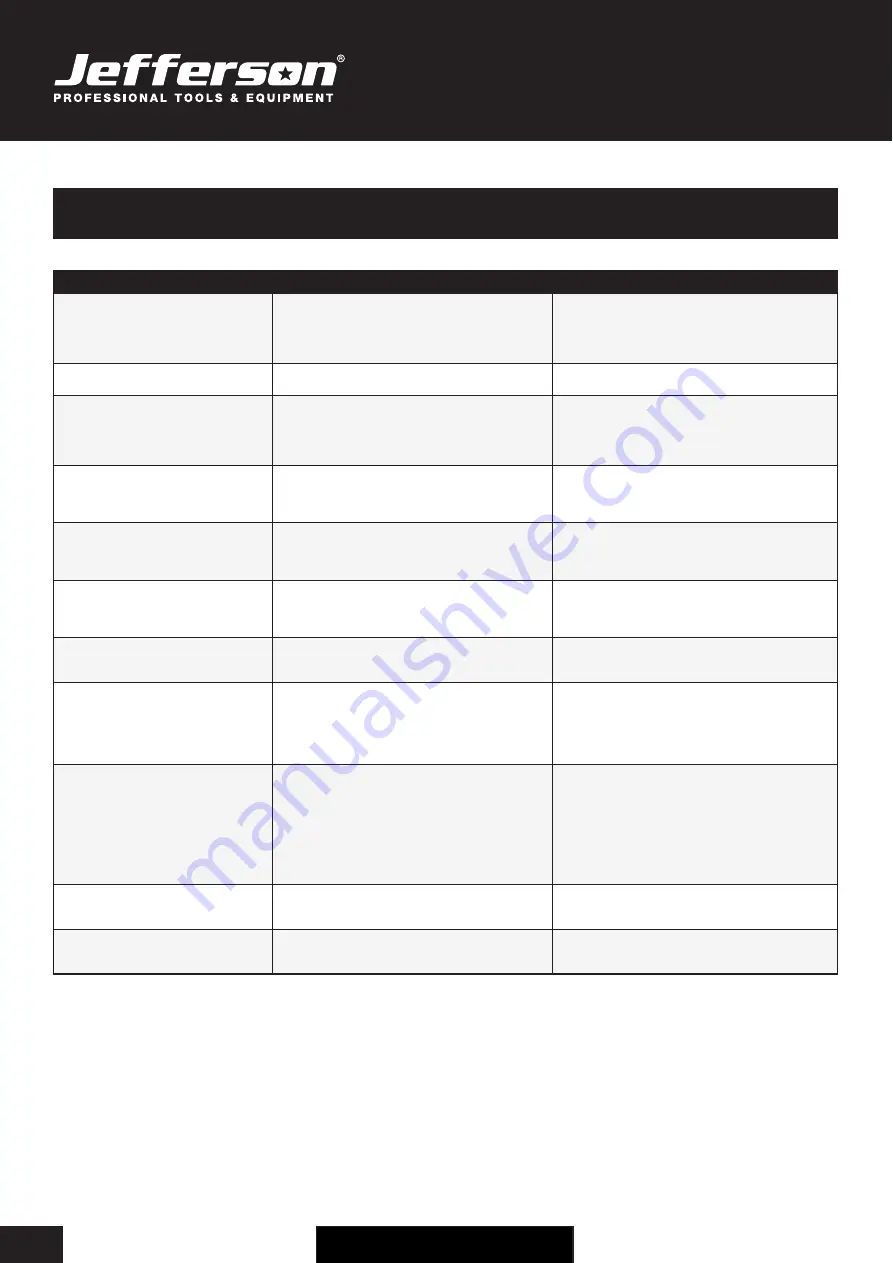

TROUBLESHOOTING

FAULT

CAUSE

REMEDY

Tank pressure drops continually.

Air leak, check all connections.

Locate and rectify leak. Run the compressor at maximum

pressure then switch off and disconnect. Brush a soapy

water solution over the connections and look for bubbles.

Tighten any connections showing leaks. If problem

persists contact your authorised service agent.

Tank pressure won’t build up.

The drain valve is open.

Close the tank drain valve.

The compressor won’t switch off.

The safety valve blows off.

Compressor does not stop when maximum

pressure is reached.

Pressure switch fails to stop motor. Faulty pressure

switch.

Contact your authorised service agent.

Tank pressure won’t build up and the pump

is getting hotter than normal, inlet suction

is poor.

The compressor head gasket or valve plate is faulty.

Fault with the air filter.

Contact your authorised service agent.

Check, clean, replace air filter as required.

There is a leak from the base of the

pressure switch when the compressor is

running.

Failure of the pressure relief valve. (Located in the base

of pressure switch).

Contact your authorised service agent.

There is a leak from the base of the

pressure switch when the compressor is

stopped.

The Non-return valve (from the tank) is leaking.

Disassemble and clean, if necessary replace valve insert.

Contact your authorised service agent.

The compressor is noisy with metallic

clangs / knocks.

Bearing or piston problem.

Low oil level.

Stop the compressor and contact a specialized service

technician.

The compressor sounds like it is trying to

start (motor makes a humming noise).

Air pressure trapped on piston is resisting the starting

effort.

Faulty capacitor or fault within the electric motor.

Turn unit off and on again using the pressure switch. This

will vent air from the delivery tube.

Stop the compressor and contact a specialized service

technician.

Overload switch activated.

Startup load may have activated overload switch.

Extension lead is too long (if in use).

Head unloader not functioning.

Leave for a few minutes then press the reset button and

restart.

Remove the extension lead and test compressor by

connecting the compressor as close to the main fuse box

as possible.

Stop the compressor and contact a specialized service

technician.

Air leaks from the safety valve at pressures

less than 8 bar.

The safety valve is faulty.

Replace the safety valve.

Compressor stops and will not restart.

Power failure.

Motor Failure.

Check electrical supply and fuse.

Contact your authorised service agent.