13

USER MANUAL

JEFMIG185-A – JEFMIG210-A

185A MIG WELDER - 230V 50Hz

210A MIG WELDER - 230V 50Hz

www.jeffersontools.com

PRECAUTIONS

•

Ensure that there is free air circulating around the outer casing of the

welder, and that the air vents are unobstructed.

•

Welding arc can seriously damage your eyes. Both the operator and

spectators must always use a suitable welding face shield or helmet, with

suitable filter lenses for the welding processes.

•

Suitable Personal Protection Equipment (PPE) including gloves and

working clothes should be worn at all times.

•

Always check and ensure that the pressure regulator and gauges (if fitted) are working correctly before use.

•

Regulators are designed to be used with specific gases, it is important that you use the correct regulator for the gas required.

•

Do not lubricate the regulator.

•

Inspect gas hoses, cables and clamps before use to ensure they are in good condition.

•

Remove all flammable materials from the working environment before use.

•

Keep a fire extinguisher nearby at all times. The extinguisher should be Dry Powder or CO

2

type.

•

Do not remove any of the casing panels for repair or maintenance unless the machine is disconnected from the supply,

and never use the machine with any of the panels removed. All repairs should be carried out by qualified engineers using

Jefferson approved parts. Contact your nearest Jefferson Dealer for details.

•

Never use or store this equipment in a wet or damp environment and do not expose the equipment to rain during use.

•

The MIG welding process uses an inert gas to protect the weld pool. It is important to ensure the appropriate gas is being used.

•

Never use an unknown or unidentifiable gas supply or gas from a damaged or unmarked cylinder.

•

Do not lift or move a gas cylinder by holding he cylinder by the valve.

•

Do not expose the cylinder to a heat source or sparks while in storage or in use.

•

Stop welding immediately if any static / electric shocks are felt or detected. Do not attempt to weld using the equipment until

the source of the fault is identified and repaired.

•

Do not point the MIG torch at anyone when in use.

•

Do not touch the MIG torch nozzle until the welder is switched

OFF

and the nozzle has been allowed to cool off.

•

Never connect, disconnect, or attempt to service the MIG torch, until the machine is switched

OFF

and disconnected from

the mains power supply.

•

Never allow the equipment cables to become wrapped around the operator or any bystanders in the working environment.

8. Operation Guidelines

Before welding:

•

Read and understand the safety rules section of this manual

•

Ensure all flammable materials are removed the work area

•

Ensure there is good ventilation around the welding unit and the working environment

•

Enure you have a fire-extinguisher in the vicinity of the working environment and that it is ready for use in the event of fire

•

Wear appropriate protective clothing and insulated leather gloves (check with your nearest Jefferson Dealer for advice)

Step 1:

Connect work clamp onto metal to be welded, or to the metal workbench where the object is mounted and electrically

connected.

Step 2:

Before plugging in, adjust the amperage and wire feed speed according to material type and thickness, and the wire size.

Step 3:

Check the power switch is in the

OFF

position, and then plug the power cable into the electrical outlet.

Step 4:

While holding the torch with the wire and tip clearly out of the way of any grounded objects, turn the power switch to

ON

position.

Step 5:

Orient yourself on the area to be welded, and then place the face shield over your eyes.

Step 6:

Press (and hold) the torch button and stroke the area to be welded

with the electrode wire to ignite the arc.

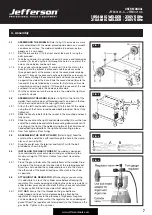

Step 7:

Once the arc is ignited, tilt the electrode wire forward at an angle of

approximately 35° (as shown in

Fig.15

).

Step 8:

When the weld is complete, release the torch button and lift the wire

clearly away from any grounded object, set the Face Shield down and turn

the Power Switch to the “

OFF

” position.

Step 9:

Unplug the Power Cord from the electrical outlet.

WARNING: WEAR APPROPRIATE PERSONAL PROTECTION EQUIPMENT AT ALL TIMES

Never look at the ignited arc without approved, arc shaded, eye protection in a full-face shield. Permanent

eye damage or blindness can occur. Skin burns can occur. Never breathe arc fumes.

Fig.15

Electrode wire angle

Summary of Contents for JEFMIG185-A

Page 1: ...User Manual v 1 1 JEFMIG185 A JEFMIG210 A...

Page 2: ......