www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

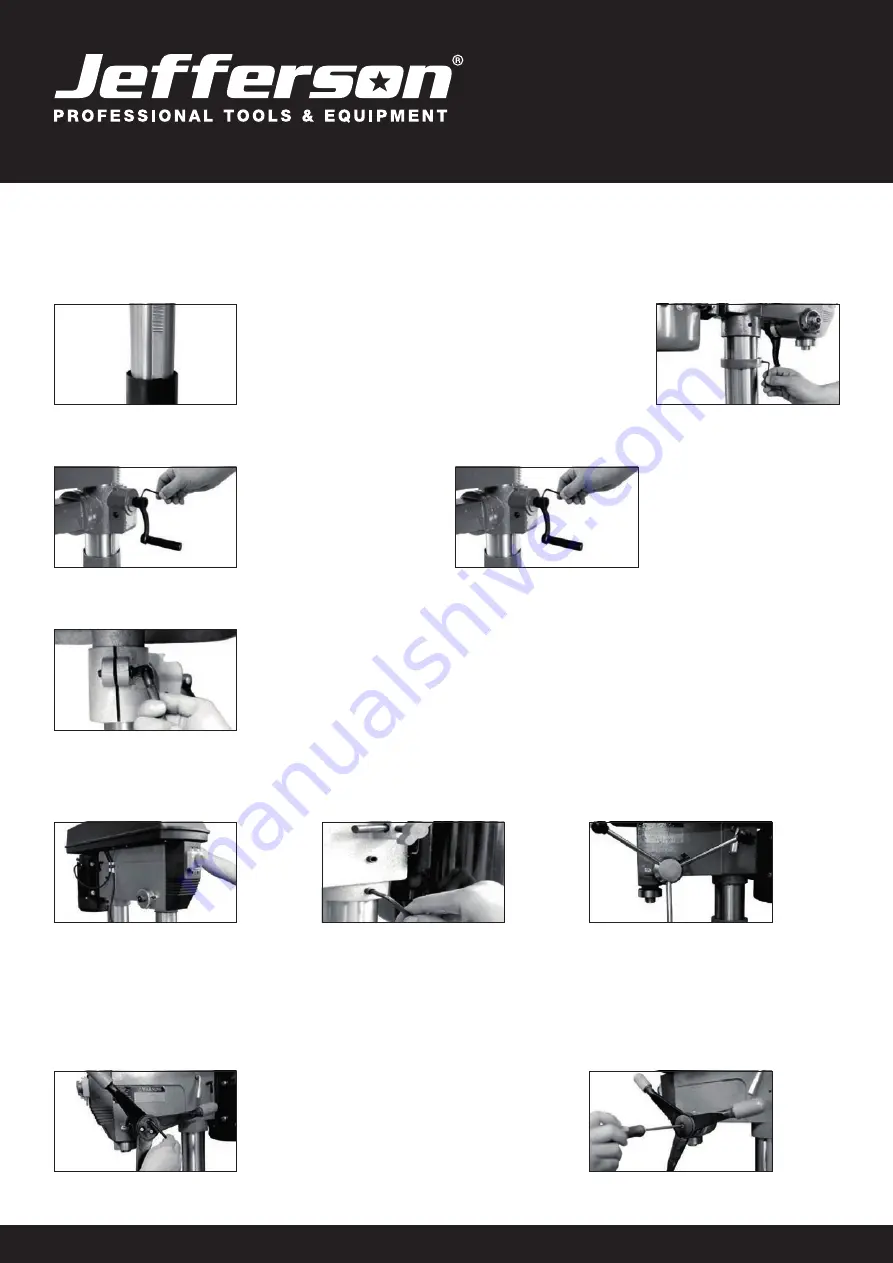

6. ASSEMBLY

MAIN HOUSING

RACK & TABLE (Continued)

Fig.8

Fig.9

3. Slide the rack all the way down until it locates into the lower column

support(Fig. 8). Slide the collar, tapered side facing down, over the

column until it locates the rack.

Tighten the grub screw on upper collar (Fig.9).

Fig.10

Fig.10

4. Fix table adjustment handle on

the support (Fig. 10).

4. Fix table adjustment handle on

the support (Fig. 10).

Fig.10

5. Assemble table onto table

support, tighten in place with

table lock (Fig. 11).

1. Lift the main housing and slide

it down onto the column as far as

it will go (Fig. 12). Before securing

the housing, ensure the spindle

aligns with the table and base.

3. To fit the feed wheel handles,

screw them into feed wheel hub

(Fig. 14).

2. To secure in position tighten

the grub screws on the left and

right hand sides of the housing

(Fig. 13).

4. For some cast iron feed

handle, lighten the 3 grub screws

to wheel hub (Fig.15) then fix the

plastic case on cast iron feed

handle as shown Fig. 16.

Fig.12

Fig.13

Fig.14

Fig.15

Fig.16