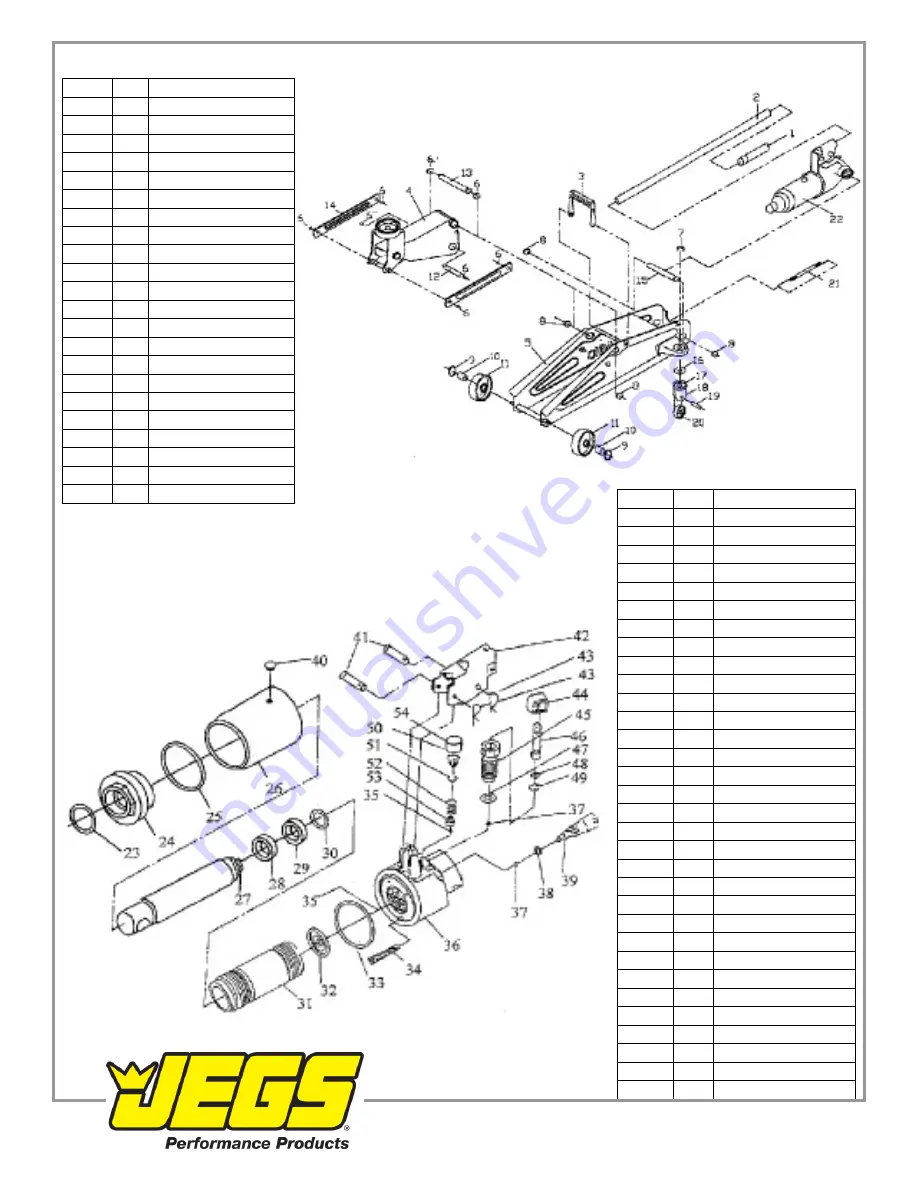

Parts List and Diagrams

Part #

Qty

Description

1

1

Cap & Release Valve

2

1

Handle

3

1

Portable Handle

4

1

Lifting Arm

5

1

Side Board

6

8

Circlip

7

2

Nut

8

4

Circlip

9

2

Flat Washer

10

2

Spacer, Front Wheel

11

2

Front Wheel

12

1

Cross Head Pin

13

1

Spindle, Lifting Arm

14

2

Radius Link

15

1

Anchor Bolt

16

2

Steel Ball Bearing

17

2

Bolt, Caster Wheel

18

2

Fork, Caster Wheel

19

2

Spindle, Caster Wheel

20

2

Caster Wheel

21

1

Return Spring

22

1

Hydraulic Unit Assembly

Part #

Qty

Description

23

1

Top Nut O-Ring

24

1

Top Nut

25

1

Small Nylon Washer

26

1

Oil Reserve

27

1

Ram

28

1

Collar

29

1

Cup Seal Ram

30

1

O-Ring Seal

31

1

Cylinder

32

1

Copper Washer

33

1

Large Nylon Washer

34

1

Screen Filter Body

35

2

Steel Ball 3/16”

36

1

Power Unit Casting

37

2

Steel Ball 1/4”

38

1

Release Valve O-Ring

39

1

Release Valve

40

1

Filler Plug

41

2

Connector Pin

42

1

Operating Link

43

2

Split Pin

44

1

Spring Clip

45

1

Pump Cylinder

46

1

Piston

47

1

Copper Washer

48

1

Back up Ring

49

1

O-Ring

50

1

Overload Valve Screen

51

1

Overload Valve O-Ring

52

1

Spring Overload Valve

53

1

Spring Guard

54

1

Cap

1-800-345-4545 jegs.com