MAINTAINENCE

1. Periodically check the tightness of mounting bolts and electrical connections. Remove all dirt or corrosion and always

keep clean.

2. Do not attempt to disassemble the gear box. Repairs should be done by the manufacturer or an authorized repair

center.

3. The gear box has been lubricated using a high temperature lithium grease and is sealed at the factory. No internal

lubrication is required.

REPLACING THE WIRE ROPE

1. If the wire rope has become worn or is beginning to show signs of strands breaking it must be replaced before being

used again. To do this, remove the defective rope by free spooling. Remove the M5 x 5mm bolt on the drum and

release the rope.

2. Insert the end of new rope and secure the M5 x 5mm bolt tightly.

3. Engage the clutch and re-spool the new rope on the drum keeping tension on the rope as it spools. Ensure that the

rope is re-spooling in the under wind position.

WARNING

- Only replace the wire rope with the identical replacement part recommended by the manufacturer.

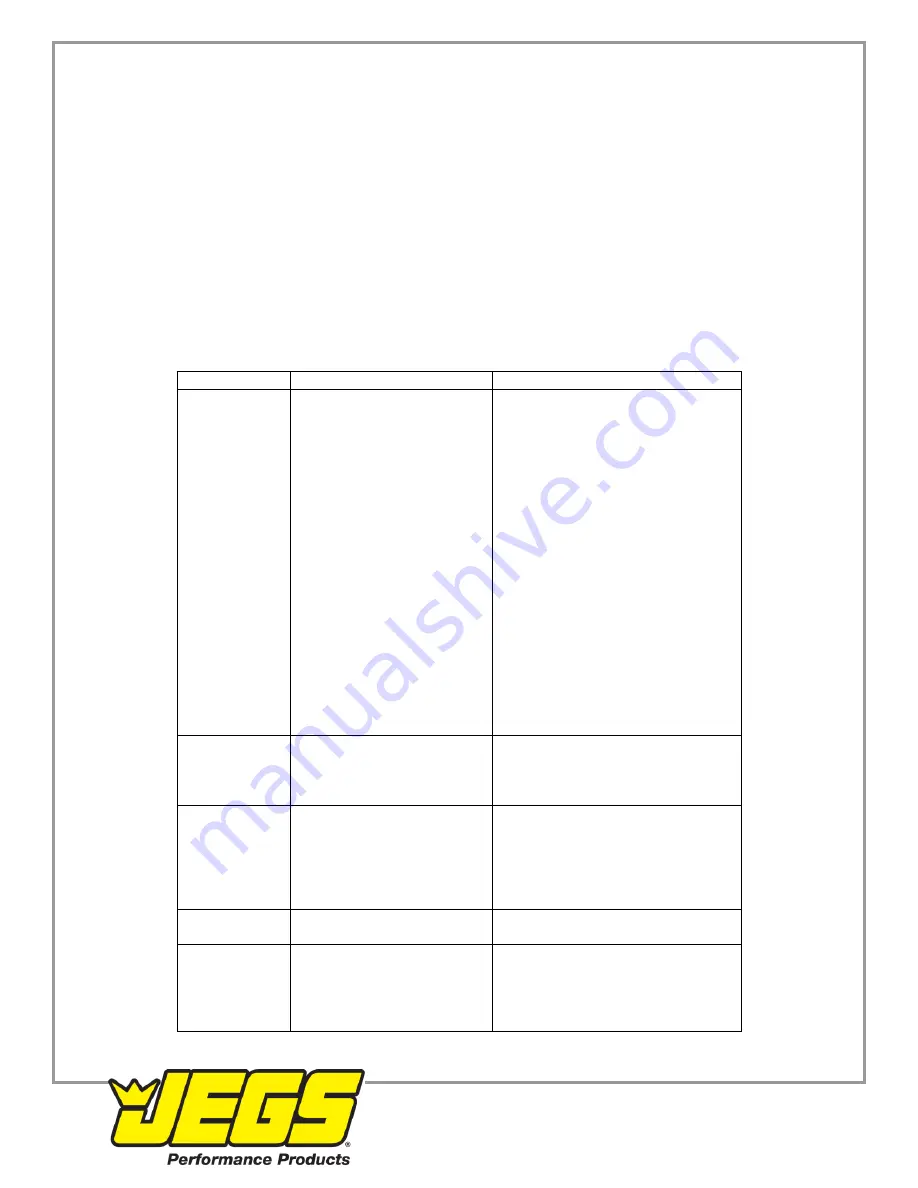

SYMPTOM

POSSIBLE CAUSE

SUGGESTED ACTION

Motor does

not turn on

-Switch Assembly not

connected property

-Loose battery cable

connections

-Solenoid malfunctioning

-Defective Switch Assembly

-Defective motor

-Water has entered motor

-Insert Switch Assembly all the

way into the connector.

-Tighten nuts on all cable

connections.

-Tap solenoid to loosen contacts.

Apply 12volts to coil terminals

directly. A clicking indicates

proper activation.

-Replace Switch Assembly

-Check for voltage at armature

port with switch pressed. If

voltage is present replace motor.

-Allow to drain and dry. Run in

short bursts without load until

completely dry.

Motor runs but

cable drum

does not turn

-Cam Ring (clutch)

not engaged

-Move Cam Ring to the in

position. If problem persists, a

qualified technician needs to check

and repair.

Motor runs

slowly or

without normal

power

-Insufficient current or

voltage

-Battery weak, recharge. Run

winch with vehicle motor running.

-Loose or corroded battery cable

connections. Clean, tighten, or

replace

Motor

overheating

-Winch running time too

long

-Allow winch to cool down

periodically.

Motor runs in

one direction

only

-Defective or stuck

Solenoid

-Defective Switch

Assembly

-Tap solenoid to loosen contacts.

-Repair or replace solenoid.

-Replace Switch Assembly

TROUBLESHOOTING

1-800-345-4545 jegs.com