12

5.1.5.4 Press the Right button (4) again to adjust the inductance of the welding arc. Use the Right Knob (3) to adjust the

inductance from

‐

10 (less inductance) to +10 (more inductance).

The default value of inductance is 10, it is recommended to keep this value unless the operator is an experienced welder.

5.1.5.5 Press the Right Button (4) again to return to the main wire speed/voltage adjustment screen. If the control panel is

not adjusted after 5 seconds it will also return to the primary MIG adjustment mode. Or press the Left/Right (1)/(3) to

return to the primary MIG adjustment mode directly.

5.1.5.6

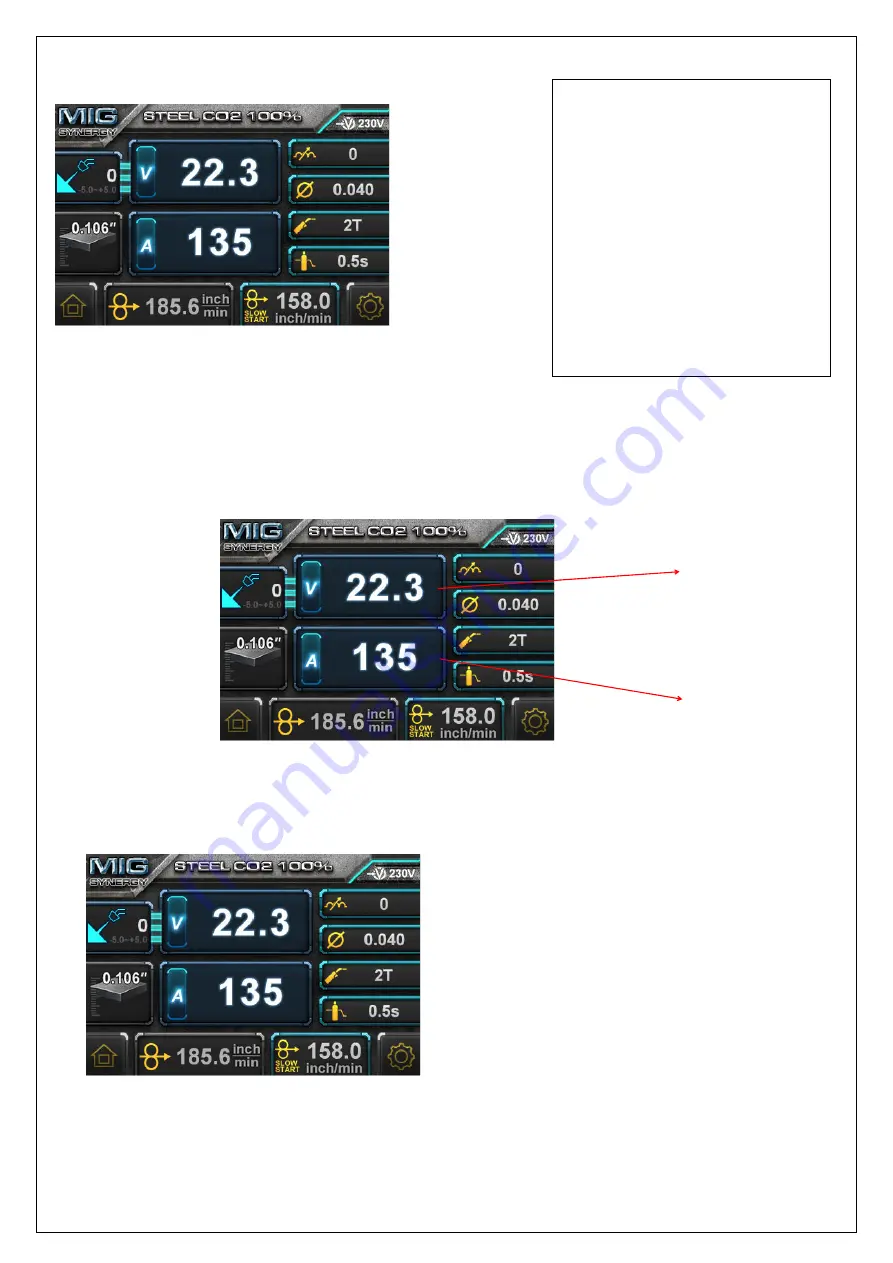

During welding the screen display will change to show the actual welding voltage and welding current as

pictured below

5.1.5.7 2T/4T function: press the Right Button (4) ,2T/4T Selection Switch to move between 2T and 4T modes. 4T operation

means the trigger is pulled once to start welding and pulled again to stop.

This is useful for long weld joints. 2T mode,

the trigger must be depressed and held during welding.

A quick note regarding inductance –

this effectively adjusts the intensity of

the welding arc.inductance makes the

arc ‘softer’, with less weld spatter.

Higher inductance gives a stronger

driving

arc

which

can

increase

penetration.

Optimum

inductance

settings are affected by many welding

variables

such

as:

material

type,

shielding

gas

joint

type,

welding

amperage, wire size.

welding amperage, wire size.

Actual welding voltage

Actual welding current