22

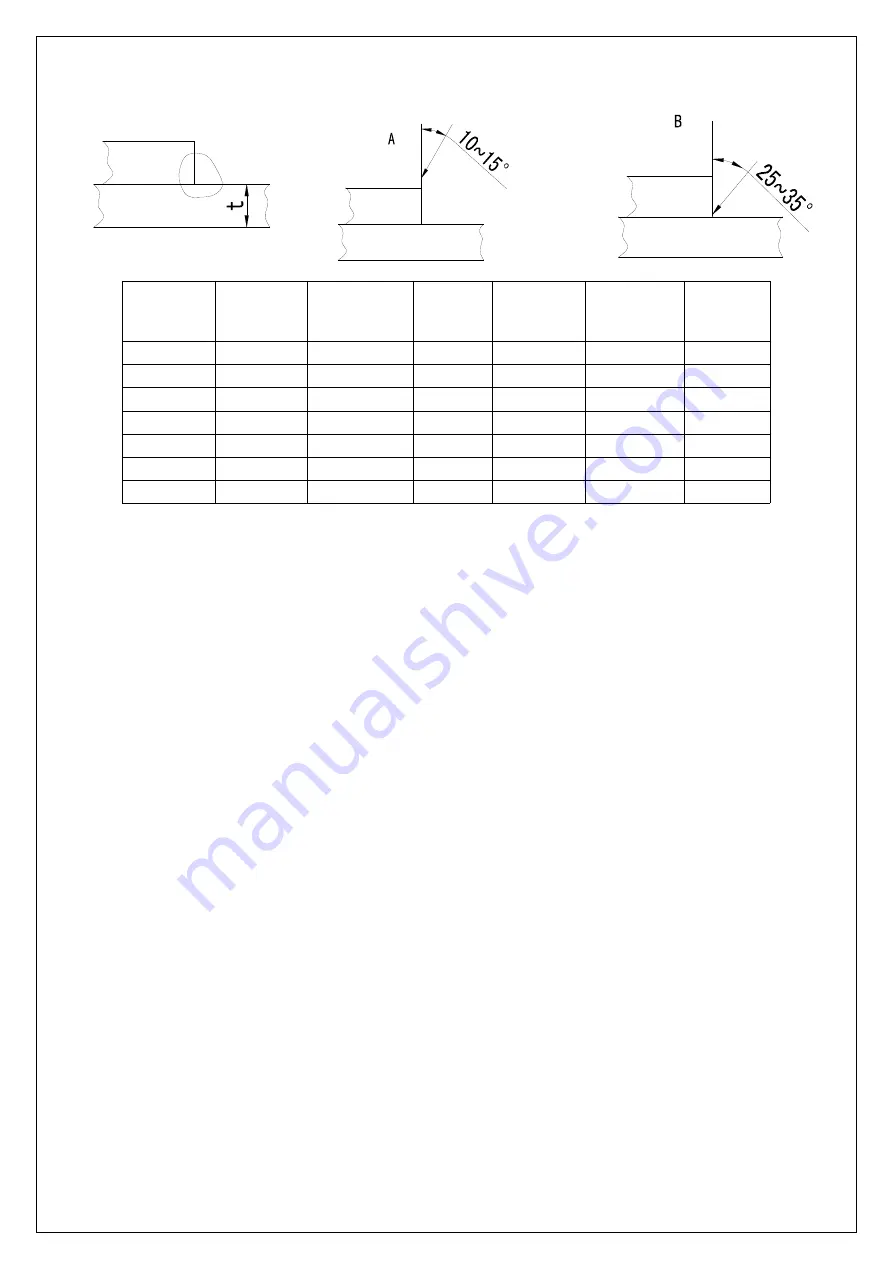

Parameter for Lap Welding (Please refer to the following figure.)

Plate

thickness

t

(

in

)

Welding

position

Wire

φ

(in)

Welding

current

(

A

)

Welding

voltage

(

V

)

Welding

speed

(

in/min

)

Gas

volume

(

L/min

)

0.032

A

0.032~0.035

60~70

16~17

15.75~17.72

10~15

0.047

A

0.040

80~100

18~19

17.72~21.65

10~15

0.063

A

0.040 ~ 0.047

100~120

18~20

17.72~21.65

10~15

0.079

A or B

0.040 ~ 0.047

100~130

18~20

17.72~21.65

15~20

0.091

B

0.040 ~ 0.047

120~140

19~21

17.72~19.69

15~20

0.126

B

0.040 ~ 0.047

130~160

19~22

17.72~19.69

15~20

0.178

B

0.047

150~200

21~24

15.75~17.72

15~20

9.CAUTION

1. Working environment

⑴

Welding should be carried out in a relatively dry environment with its humidity of 90% or less.

⑵

The temperature of the working environment should be within

‐

10

C to 40

C.

⑶

Avoid welding in the open air unless sheltered from sunlight and rain, and never let rain or water infiltrate the machine.

⑷

Avoid welding in dusty area or environment with corrosive chemical gas.

⑸

Avoid gas shielded arc welding in environment with strong airflow.

2. Safety tips

Over

‐

current/overheating protection circuit is installed in this welding machine. If the output current is too high or

overheating generated inside this welding machine, this welding machine will stop automatically. However, inappropriate

use will still lead to machine damage, so please note:

1. Ventilation

High current passes when welding is carried out, thus natural ventilation cannot satisfy the welding machine’s

cooling requirement. Maintain good ventilation of the louvers of this welding machine. The minimum distance

between this welding machine and any other objects in or near the working area should be 30cm. Good ventilation

is of critical importance for the normal performance and service life of this welding machine.

2. No over

‐

current.

Remember to observe the max load current at any moment (refer to the optioned duty cycle). Make sure that the

welding current should not exceed the max load current.

If welding is carried out under a current which is higher than the max current, over

‐

current protection will occur; the

output voltage of the welding machine will be not stable; arc interruption will occur. In this case, please lower the

current.

3. No over

‐

load.

Over

‐

load current could obviously shorten the welding equipment’s life, or even damage the machine.

A sudden halt may occur while the welding operation is carried out while this welding machine is of over

‐

load status.

Under this circumstance, it is unnecessary to restart this welding machine. Keep the built

‐

in fan working to bring

down the temperature inside the welding machine.

4. Avoid electric shock.

An earth terminal is available for this welding equipment. Connect it with the earth cable to avoid the static and

electric shock.