Page 20

How to operate

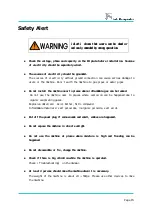

Input shaking speed

1.

Press SHAKER/SET key.

2.

Press UP/DOWN key.

Input RPM.

3.

Press Enter Button.

Finish to set value.

4.

Press START/STOP key.

Shaking starts in clockwise rotation.

※

Recall function of RPM value

- Previous RPM value starts if new RPM is set again.

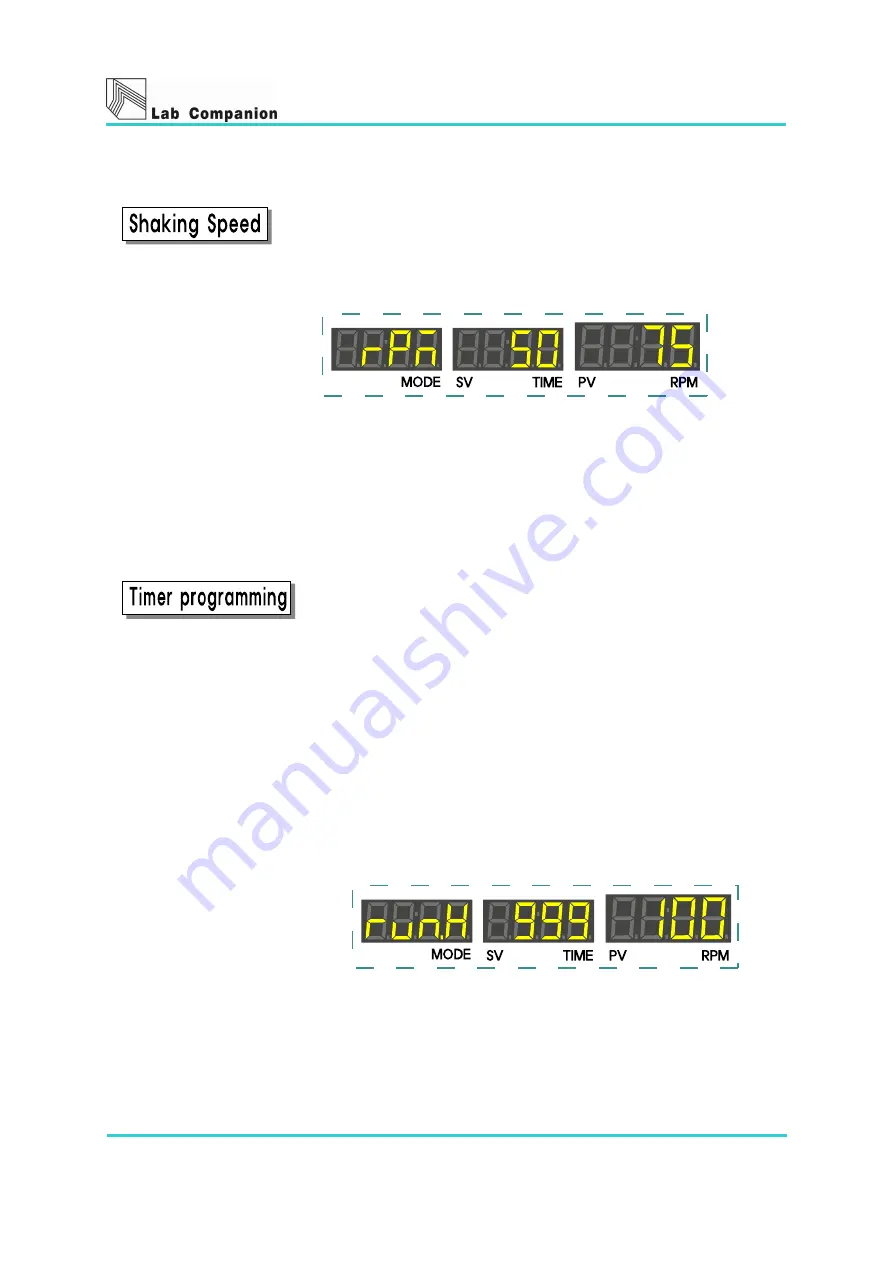

Timer programming

1. Time Programming

- Programming time can not be done during shaking. So, stop shaking by

pressing START/STOP key and start programming.

1) Input total run time

1.

Press SHAKER/SET key Twice.

This section is for setting total run time.

¡run.H¡ shown on MODE display.

2.

Press UP/DOWN Button to set Time and then press

ENTER key to store the value. (Max Input Time: 1~999

hours)

After setting the value, TIMER LED is on.

3.

Press SHAKER/SET key.

This section is for setting minute and seconds.

¡run.S¡ shown on MODE display

4.

Press UP/Down key to set minute and seconds and then

press Enter key to store the value.

(Max Input Time: 10seconds~ 59 minutes 59 seconds)