3

AN INTRODUCTION TO SMOKE TECHNOLOGY

Smoke Machine Markets

Jem / Martin smoke machines are categorised into 2 ranges: The

Professional

and the

Club / DJ

range.

If a product is branded as a “Martin” product this is aimed at the

Club / DJ

market.

All products branded as a “JEM” product are classed as

Professional

and are aimed at the higher end touring /

installation market.

All JEM / Martin Smoke products can be used across both of the different markets without any

compromise of

performance or features.

Smoke machine principles:

All JEM / Martin

conventional

smoke machines utilise the same technology:

In Brief:

When the

run button

on the

remote

is pressed,

smoke fluid

is pumped from a removable

container

situated within the machine via the flexible fluid pipe into an

oscillating piston pump

.

The

fluid

passes through the

pump

and enters the

heat exchanger

were the

fluid is vaporised

and

exits as thick, white

smoke

.

The

heat exchanger

is comprised of a

heating element

and a

coil

of copper or steel tubing between 3 and 6

metres in length. This is cast into a mass of

aluminium

.

The

heat exchanger

is heated via the

heating element

.

This is controlled by a

J Type thermocouple

fitted to the

heat exchanger.

The

temperature

is determined by the

calibration

of the

main control PCB

.

Once the working

temperature

is reached, the

main control PCB

will allow the

pump

to be operated and the

machine will now be ready to

run

.

Haze machine principles:

The JEM ZR24/7 and Magnum Hazer work on the same smoke generation principles as the JEM / Martin

smoke machines.

The only difference is the smoke output on a hazer exits into a

metal chamber

where there is a

fan

creating a

fast moving air stream

. This air stream

disperses

the smoke output and creates the

haze

.

Again the principles are identical to that of a

conventional

smoke machine.

There is a

pump, heat exchange, PCBs

and

onboard controls

. The major difference is the

air chamber

.

A

radial fan

is used with this system. It is used to allow the exiting smoke to have the

maximum dispersal

.

As with several of the smoke machines, the haze machine has a

low fluid shut off

system. This is an

electronic temperature control device

that measures the

temperature

of the

heat exchange

over a short

period. If the

temperature

has not changed but the unit has been

pumping

; the unit will assume that the

system has

run out of fluid

and shut down.

This prevents the system from running dry and burning out

the pump.

Summary of Contents for ZR12-AL

Page 1: ......

Page 10: ...10 ZR12 MACHINE OVERVIEW The Outside ANALOGUE CONTROL 3 PIN DMX ANALOGUE LINK STATUS LIGHTS ...

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

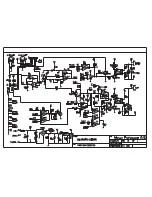

Page 23: ...YELLOW BLUE WHITE ZR12 DMX REMOTE TEST SWITCH BACK OF SWITCH IN4007 ...