ZR33-DMX USER GUIDE

Using DMX 512

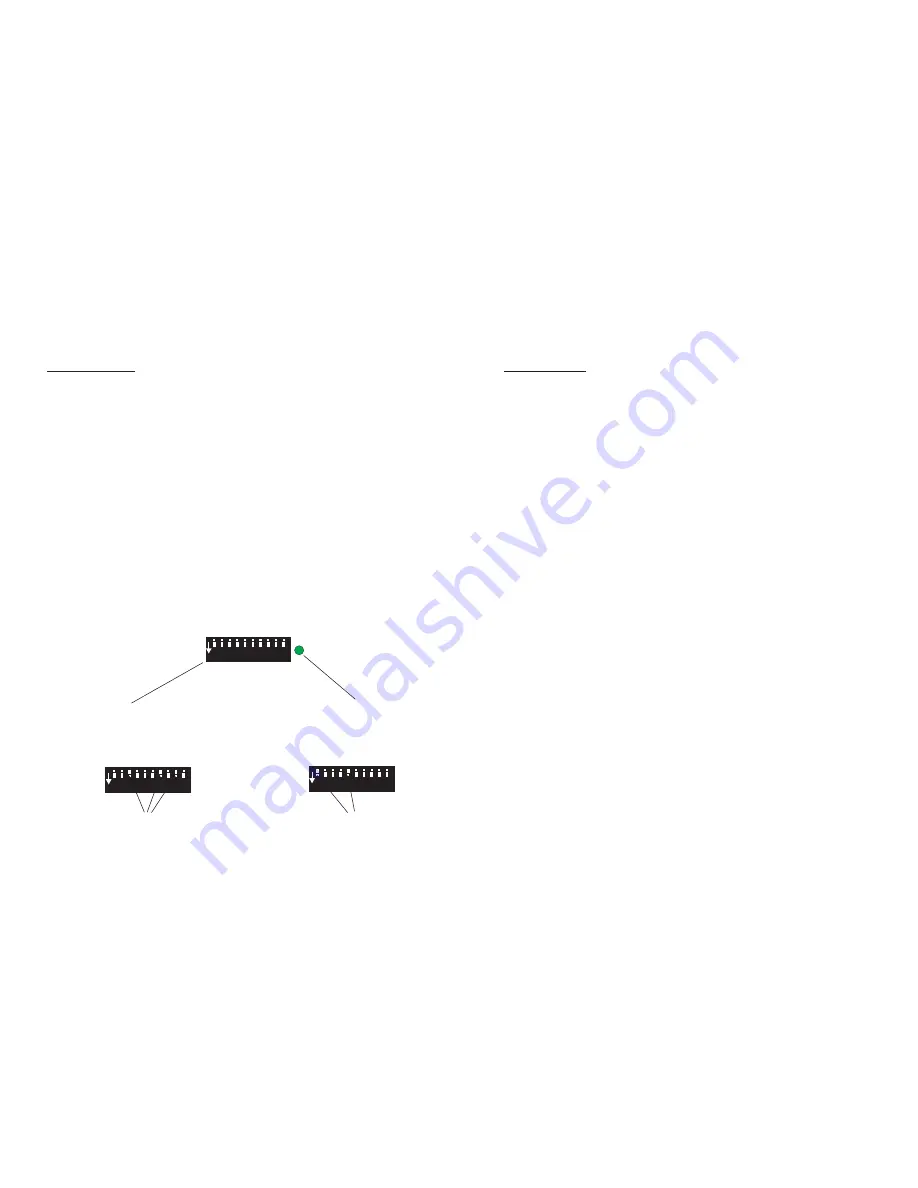

Within the lighting industry, the DMX communication protocol is widely used for

remote control of lighting and other equipment. The

is fitted with a DMX 512

compliant interface as standard, giving the user the possibility of controlling the smoke

and light from a single source. The

uses a single channel to fire and control the

output level; the interface can be addressed from channel 1 to channel 512. The

address is set using the 10 way dip switch at the rear of the machine. To address the

channel, convert the channel number to binary and set this number on the switches (on

is down). There are some samples of different channel settings below.

The

is fitted with two XLR sockets, one is for DMX IN & one is for DMX

OUT, enabling the

to be used in a chain. When there is valid DMX, i.e. the XLR

is connected and the desk is powered, the small green LED will light. However, if there

is no address set, the LED will not light and DMX will be disabled. If an address is set

and DMX is present the machine will automatically start to heat up and after 10 - 12

minutes you will be able to operate the machine using DMX. Increasing the DMX level

will increase the smoke output level.

ZR33

ZR33

ZR33

ZR33

1 2 3 4 5 6 7 8 9 10

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

ON

ON

ON

Valid DMX LED

Address Switches

512

512

256

256

128

128

64

64

32

32

16

16

8

8

4

4

2

2

1

1

DMX Value

Switches 3,7, &9 on

Address set to 324

Switches 1 & 5 on

Address set to 17

PAGE 8

MARTIN MANUFACTURING (UK) PLC

ZR33-DMX USER GUIDE

Getting Started

•

•

•

•

Once you have selected the best position for the

you can begin to use

the machine. Check that the mains power supply matches the voltage and

frequency on the serial number label. If not, contact your JEM dealer for

advice.

Now set the mains switch, at the rear of the machine, to the ‘ON’ position

and press the grey “stand-by” button.

Allow around 10 -12 minutes for the machine to reach operating temperature

While it heats up you should check the level in the fluid container, the

container can hold up to 9.5 litres of fluid.

NOTE! Do not allow the

to run out of fluid. Serious damage may

occur if the machine is operated when no fluid is connected.

When the machine has reached working temperature the green “ready” LED

will light on the rear of the machine and the machine can now be operated.

Check the “output” knob is turned fully clockwise (maximum) then press and

hold the red “fog” button. The fluid pumps will start operating; if the

machine has a new container of fluid it will take a few seconds for the pumps

to prime.

When the pump has primed smoke will be visible. The output can now be set

to the desired level by turning the “output” knob. The timer may be activated

or you can simply use the “fog” button when smoke is required, Alternately

you may wish to use DMX to operate the

.

For further information on using the controller and DMX see the relevant

pages in this user guide.

When you have finished using the machine you should use the “stand-by”

button to turn off the heaters and then turn the mains switch off. If any

problems occur when operating the

please refer to the trouble

shooting guide..

ZR33

ZR33

ZR33

ZR33

PAGE 5

MARTIN MANUFACTURING (UK) PLC