Jema Autolifte A/S Industrihegnet 2 4030 Tune Denmark Tel. (+45) 48180300

info@jemaautolifte.dk

www.jemaautolifte.dk

Jema Autolifte

xxx - xxxx Co. Ltd.

MANUFACTURING PLANT & STORE

xx. xxxxxxx 11, 1 1 - 111 Warsaw

POLAND

*******************************************************************

■к**********************************************************************

WHEEL BALANCING MACHINES TYRE CHANGERS

EQUIPMENTS FOR TYRESHOPS

******************************************************************************************************************************************

Statistic number

: 001111111

Tax number

: 111 - 111 - 11 - 11

******************************************************************************************************************************************

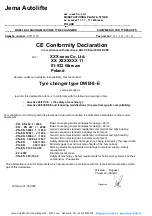

CE Conformity Declaration

in accordance with directives: 98/37/CE and 89/336/CEE

We :

XXX-xxxx Co. Ltd.

XX. XXXXXXX 11

01-932 Warsaw

Poland

declare, under our exclusive responsibility, that the product

Tyre changer type DWB-8-E

version standard

to which this declaration refers, is in conformity with the following provisions of law :

- directive 98/37/CE ( the safety of machinery );

- directive 89/336/CEE and following modifications ( the electromagnetic compatibility).

For verification of conformity with the provisions of law were consulted the harmonized standards or other norms

documents :

Basic concepts, general principles for design - Part 1;

Basic concepts, general principles for design - Part 2;

Generic emission standard, residential, commercial and light industry;

Generic emission standard, industrial environment;

Generic immunity standard, residential, commercial and light industry;

Generic immunity standard, industrial environment;

Safety distances to prevent danger zones being reached by the upper limbs;

Minimum gaps to avoid crushing of parts of the human body;

Marking electrical equipments with ratings to electrical supply - Safety

requirements.

Electrical accessories;

Safety of machinery - Safety requirements for fluid power systems and their

components - Pneumatics

- PN - EN 292 -1 / 2000

- PN - EN 292

-

21

2000

- P N - EN 50081 -1 / 1 9 9 6

- P N - EN 50081 - 2 / 1 9 9 6

- P N - EN 50082 -1 / 1 9 9 9

- P N - EN 5 0 0 8 2 - 2 / 1 9 9 7

- P N - EN

2 9 4 / 1 9 9 4

- P N - EN

3 4 9 / 1 9 9 9

- P N - EN 6 1 2 9 3 / 2 0 0 0

- 62 / 2002

- P N - EN 9 8 3 / 1 9 9 9

This declaration is valid for all products which are produced in accordance with the technical documentation which

part of this declaration.

Warsaw, 01.05.2004

Wiesław

Roguski

Chairman of Board

Signature