6

2) Preparation

1.

Check well connected of all pipes.

2.

Making sure all ball valves and switches are closed.

3.

Stop the engine of the vehicle.

4.

Temperature of oil in the engine should between 40~60

℃

. Start the vehicle for a while to heat the oil.

3) Vacuum Generation (Fig.2)

Operating air pressure: 6

~

8 bar/87

~

116PSI

Consumption of air: 150L/Min

If ONLY extract measuring glass/cylinder to be vacuum.

1.

Turn off all valves BEFORE use.

2.

Connect the air compressor to the air inlet

①

, gradually turn on the air inlet ball valve for vacuumization.

3.

Gradually turn on the air inlet valve (which equipped by customer himself) for vacuum generation.

4.

When finger reaching to the MAX. area on the vacuum gauge, turn off the air inlet valve Estimated time

for vacuum generation within 20~30seconds)

5.

Turn off air source after completion (To ensure the suction speed remains in stable negative pressure for

continuously extraction required. please continue vacuum generation)

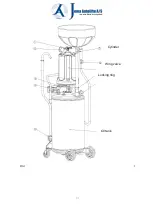

Flat

Flat head hexagonal screw

Cylinder

Oil tank

FIG.1

Summary of Contents for JA1041OD

Page 1: ...1 Pneumatic Oil Extractor Operational Manual Model No JA1041OD ...

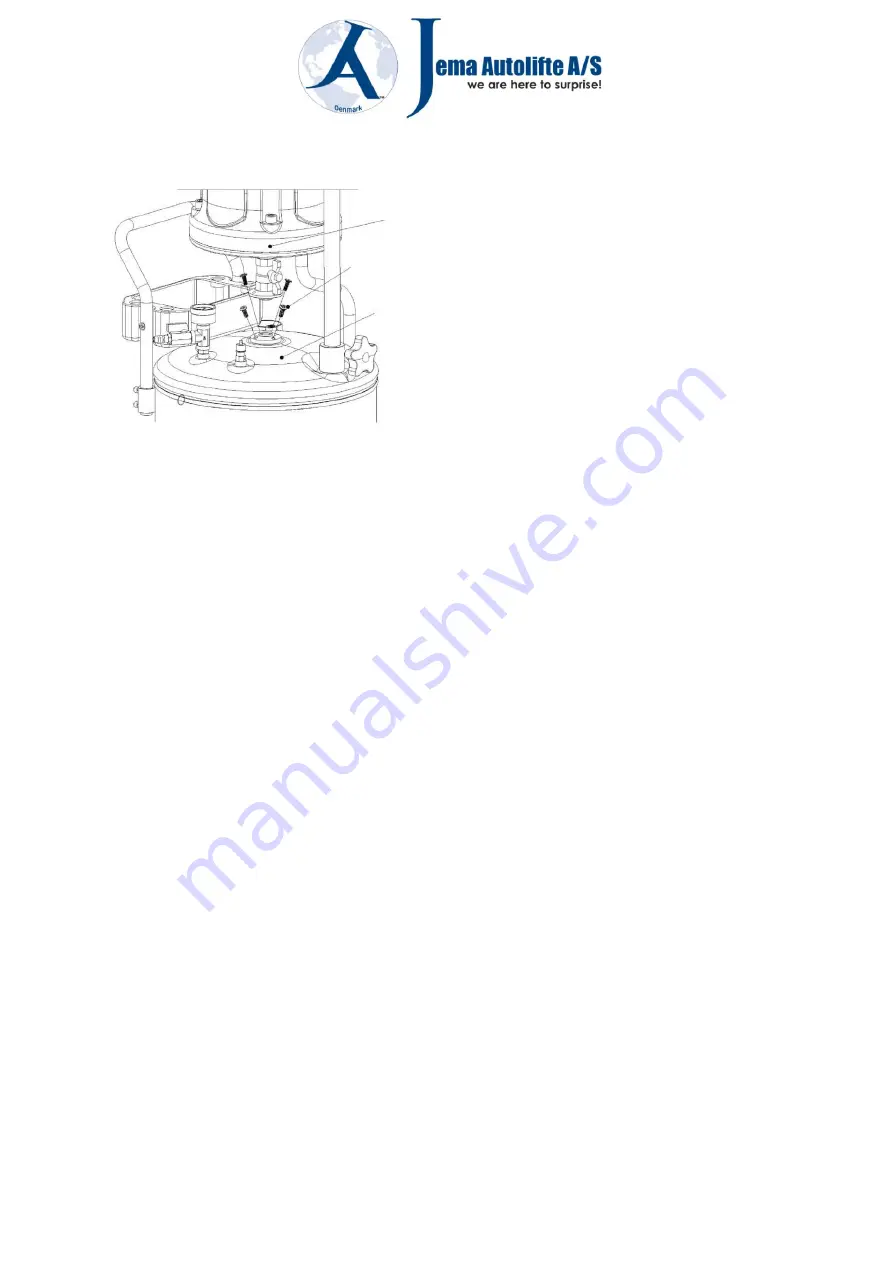

Page 12: ...12 FIG 3 2 Cylinder Locking ring Wing valve Oil tank ...

Page 13: ...13 ...

Page 15: ...15 ...