WE ARE HERE TO SURPRISE

23

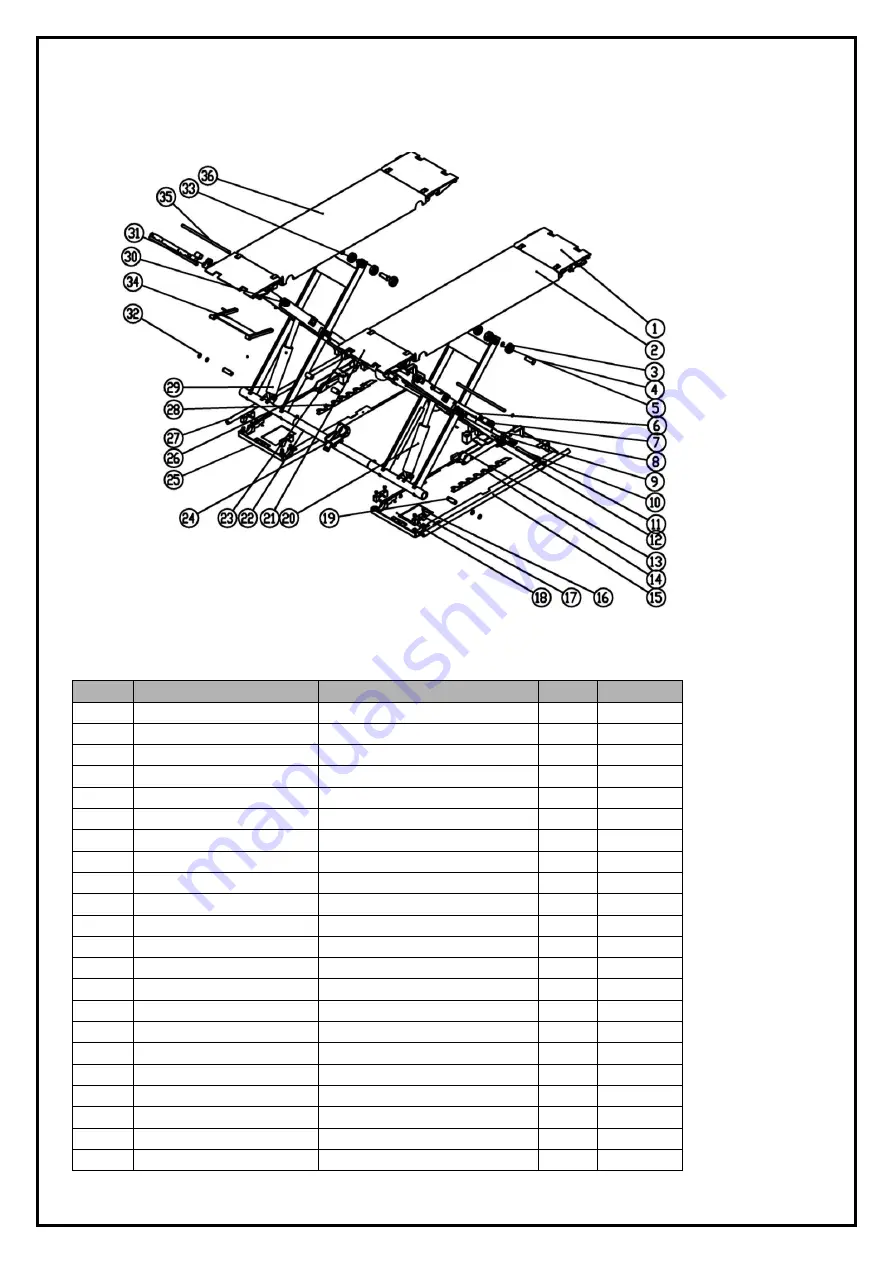

For the lift

S/N

Name

Drawing #/Spec.

Qty

Note

1

Ramp assembly A

JA3000S-A22

4

2

Platform assembly B

JA3000S-A20

2

3

Small idler wheel

JA3000S-A8

8

4

Shaft

JA3000S-A9

4

5

Circlip for the shaft

D25

4

6

Swing shaft

JA3000S-A17

2

7

Self-lock screw

JA3000S-A18/ M27

8

8

X shape shaft

JA3000S-A7

2

9

Oilless bearing

3045

12

10

Security shaft

JA3000S-A5-B14

2

11

Driving assembly

JA3000S-A5

2

12

Nylon Slider

JA3000S-A5-B6

2

13

Limit switch

1

14

Safety lock holder

JA3000S-A5-B15

1

15

Feet protector

JA3000S-A1-B7

2

16

Inside hex screw

M10x35

8

17

U-shape block

JA3000S-A4

8

18

Right base assembly

JA3000S-A2

1

19

Fasten shaft for oil tank

JA3000S-A16

2

20

Oil cylinder(right)

JA3000S-A15-B2

1

21

Guiding plate B

JA3000S-A23

2

22

Drive assembly

JA3000S-A3

1