Jema Autolifte – Denmark

- WE ARE HERE TO SURPRISE!

8

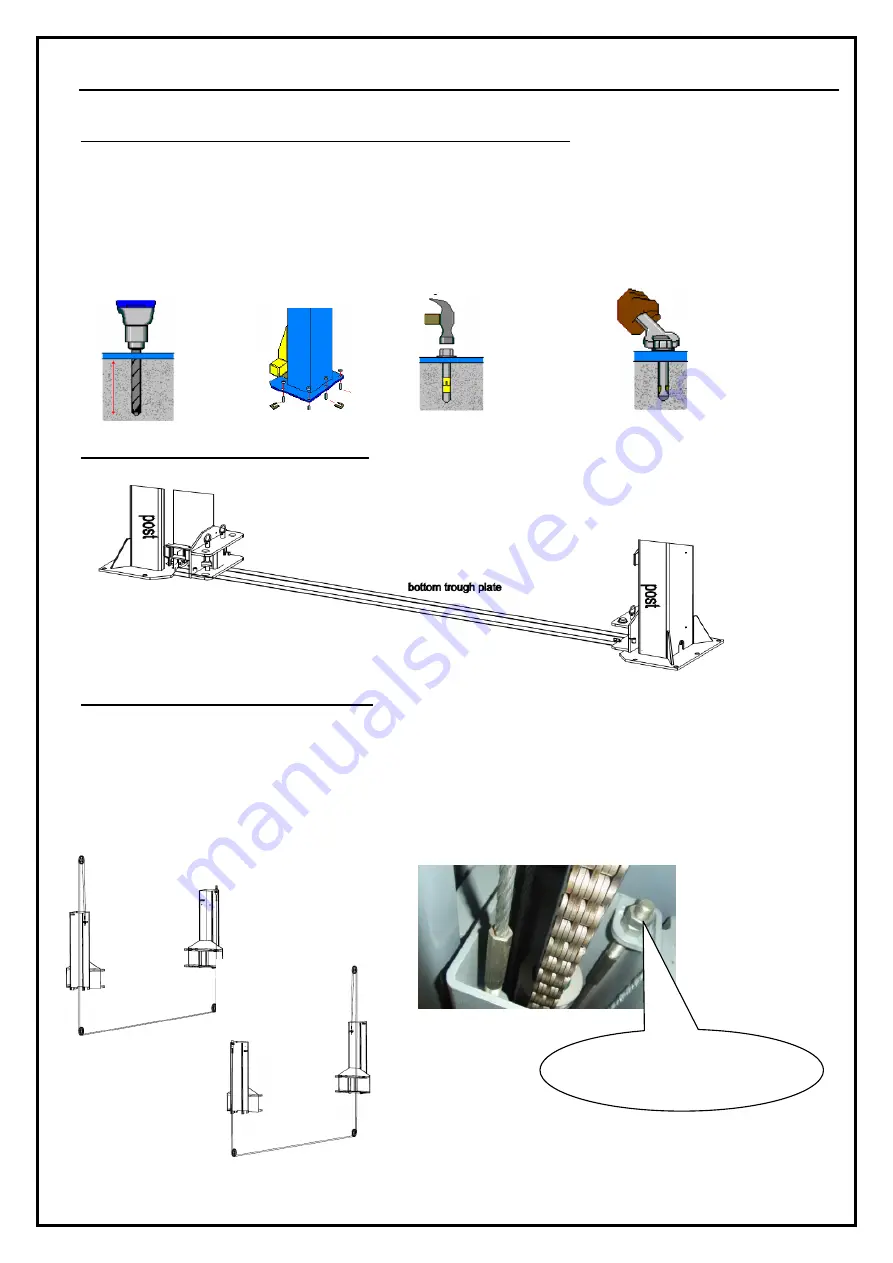

Step five: erect the posts, main post first and then the assistant post

1. Drill each anchor hole in the concrete using a rotary hammer drill. To assure full holding power, do not ream the hole or

allow drill to wobble.

2. After drilling, remove dust thoroughly from each hole and make certain that the column remains aligned with the chalk line

during this process.

3. Position the main column at the designated chalk locations and follow the same procedures step 1, 2 to position the

assistant column.

Step six

:

Install the bottom trough plate

Step seven: connect the wire rope

1. Raise and lock each carriage approximately 800mm high above the ground.

2. Make sure that the safety locks on each column are fully engaged before attempting to route equalizer cables.

3. Carriages must be equal height from the floor before proceeding.

4. With the carriages in equal position from the floor, route the equalizer cables as shown.

5. After the equalizer cables have been routed, adjust each cable so that they are equal tension.

6. Grease the wire rope with butter.(this step must be carried out )

Bolt to adjust the tightness of

the wire rope

Summary of Contents for JA3500T

Page 20: ...Jema Autolifte Denmark WE ARE HERE TO SURPRISE 20 ANNEX 2 Overall Diagram ...

Page 22: ...Jema Autolifte Denmark WE ARE HERE TO SURPRISE 22 Annex5 Wiring diagram Single phase ...

Page 31: ...Jema Autolifte Denmark WE ARE HERE TO SURPRISE 31 ...

Page 32: ...Jema Autolifte Denmark WE ARE HERE TO SURPRISE 32 ...