8

2.3 Optional parts

1. Jacking beam light

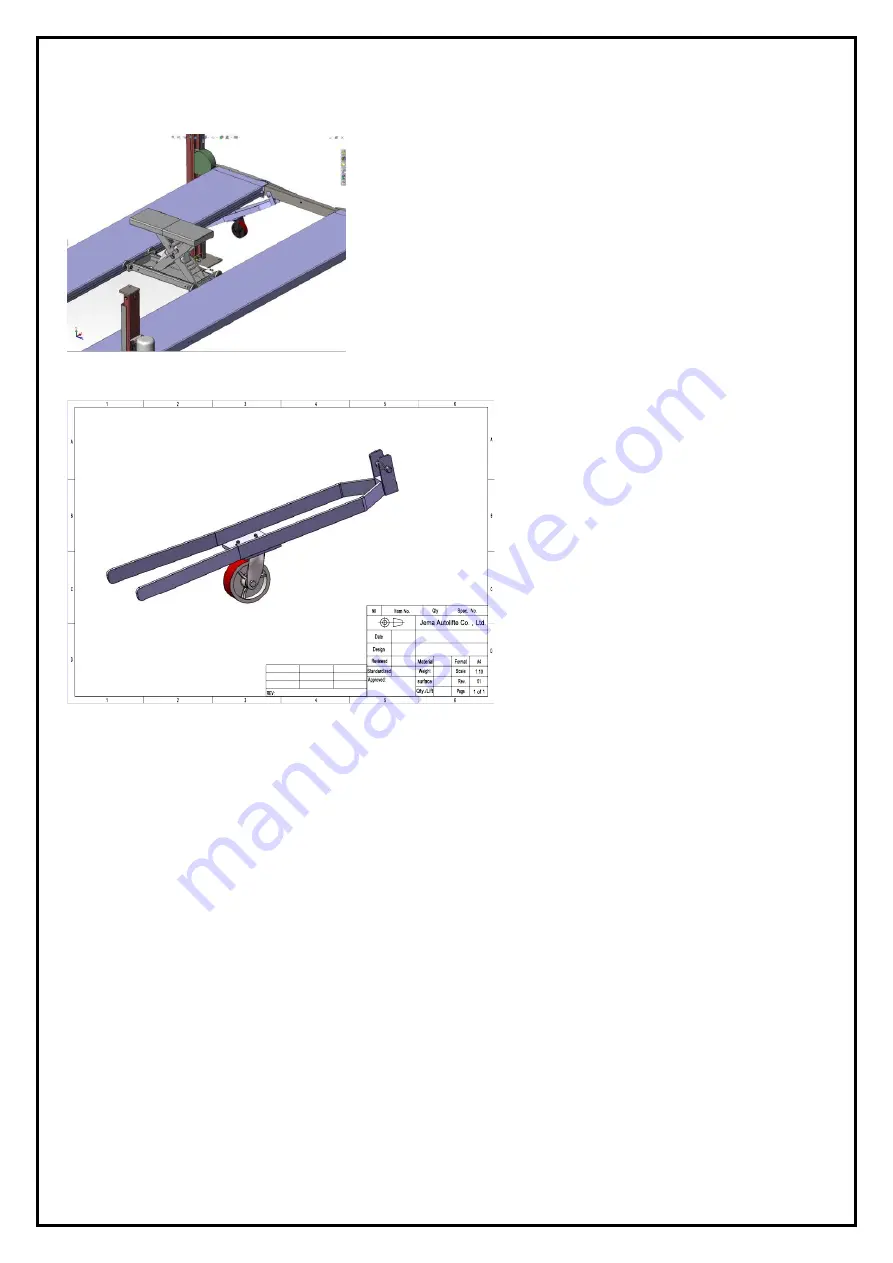

2. Mobile Kit (OPTIONAL)

3. Installation instructions

3.1 Preparations before installation

3.1.1 Tools and equipment needed.

✓

Appropriate lifting equipment

✓

Anti-abrasion hydraulic oil.

✓

Rotary Hammer Drill with 3/4’’ drill bit.

✓

Chalk and tape measure, magnetic plump, 8 meters ø15 level pipe.

✓

Sockets and open wrenches, a set of inside hex wrenches, cross and straight screw drivers.

✓

Hammer, 4pounds,

sharp nose pliers,

ø17,ø19,ø22 socket spanners

。

3.1.2 List for parts checking ---Annex 1

(

Packing list

)

Unfold the package and check if any parts missed as per Annex 1. Do not hesitate to contact us in case any parts missed, but if

you do not contact us and insist installing upon the lack of some parts, Jema Autolifte A/S as well as our dealers will not bear any

responsibility for this and will charge for any parts subsequently demanded by the buyer.

3.1.3 Ground conditions

The lift should be fixed on a smooth and solid concrete ground with its strength more than 3000psi, tolerance of flatness less than

5mm and minimum thickness of 200mm. In addition, newly built concrete ground must undergo more than 28days

’ cure and

reinforcement.

Summary of Contents for JA4000FP

Page 18: ...18 7 Annex Annex1 Packing list of the whole lift Annex2 Overall diagram ...

Page 19: ...19 Annex3 Floor plan ...

Page 20: ...20 Annex 4 Steel cable connection ...

Page 21: ...21 ...

Page 22: ...22 ...

Page 24: ...24 ...

Page 25: ...25 ...