16

5. Trouble Shooting

ATTENTION: If the trouble could not be fixed by yourself, please do not hesitate to contact us for help. We will offer our service at

the earliest time we can. By the way, your troubles will be judged and solved much faster if you could provide us more details or

pictures of the trouble.

TROUBLES

CAUSE

SOLUTION

Abnormal noise

Abrasion exists on insider surface of the

posts.

Grease the inside of the post.

Trash in the post.

Clear the trash

Motor does not run and

will not rise

The wire connection is loose.

Check and make a good connection.

The motor is blown.

Replace it.

The limit switch is damaged, or the wire

connection is loose.

Connect it or adjust or replace the limit

switch.

Motor runs but will not

rise

The motor run reversely.

Check the wire connection.

Overflow valve is loose or jammed.

Clean or adjust it.

The gear pump is damaged.

Replace it.

Oil level is too low.

Add oil.

The oil hose became loose or dropped off.

Tighten it.

The cushion valve became loose or jammed.

Clean or adjusts it.

Platforms go down slowly

after being raised

The oil hose leaks.

Check or replace it.

The oil cylinder is not tightened.

Replace the seal.

The single valve leaks.

Clean or replace it.

The overflow valve leaks.

Clean or replace it.

Manual unloading valve or electrical unloading

valve leaks.

Clean or replace it.

Rising too slow

The oil filter is jammed.

Clean or replace it.

Oil level is too low.

Add oil.

The overflow valve is not adjusted to the right

position.

Adjust it.

The hydraulic oil is too hot (above 45°

)

.

Change the oil.

The seal of the cylinder is abraded.

Replace the seal.

Inside surface of the posts is not well greased. Add grease.

Lowering too slow

The throttle valve jammed.

Clean or replace.

The hydraulic oil is dirty.

Change the oil.

The anti-surge valve jammed.

Clean it.

The oil hose jammed.

Replace it.

The steel cable is

abraded

No grease when installation or out of lifetime

Replace it.

Summary of Contents for JA5500F

Page 19: ...19 Annex2 Overall diagram...

Page 20: ...20 Annex3 Floor plan Annex 4 Steel cable connection...

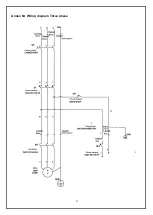

Page 22: ...22 Annex 6 Wiring diagram Three phase...

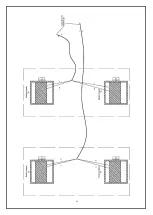

Page 23: ...23 Electric wire connections in control box Picture of the control box and connections...

Page 24: ...24...

Page 25: ...25...

Page 26: ...26...

Page 27: ...27 Annex7 Separate diagrams for the lift JA5500F...

Page 35: ...35 Annex9 Size and weight requirements on vehicles...

Page 36: ...36...