Programming the Pro-Fusion Kilns

:

This is a common firing schedule recommended by many glass companies:

300° an hour/ 1200°F / Hold 30 min to one hour (bubble squeeze)

500° an hour/1480°F /Hold 10 min

Full / 950°F /Hold 60 min

150° an hour/700°F /Hold 0 min

We are going to speed the fusing up to save time and electricity

Try the slower firing schedule for the fiber kiln for one or two firings for each sized piece, speed it

up every firing as much as the glass will tolerate. The smaller the pieces are, the faster you can go.

Below, are what we have done in our firings, from where we started and what we have achieved

over the years.

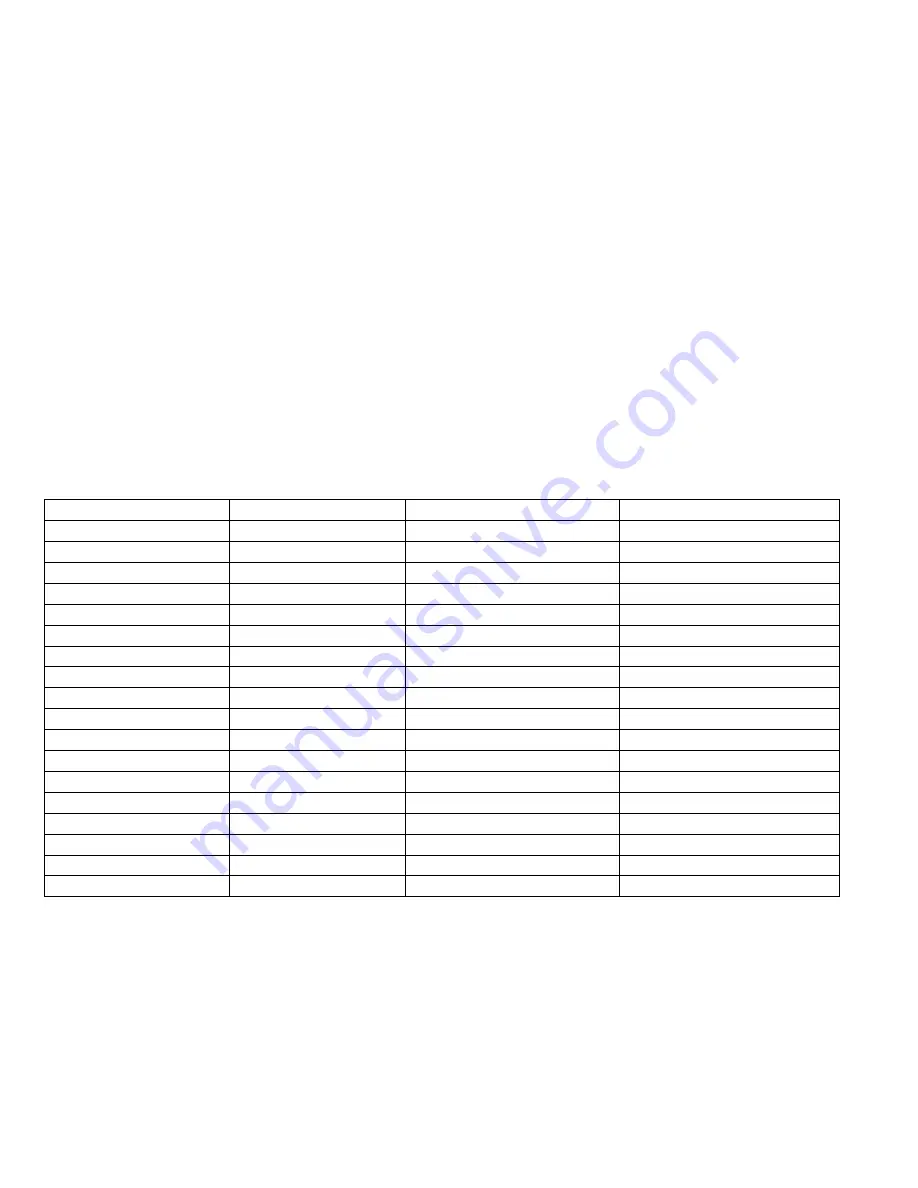

Start Here Then Try This Pro Fusion 16 Full Fuse

Brick Kiln Firing

Fiber Slow Firing

Fiber Fast Firing

Good Pro Fusion 16 Program

Ra1 300⁰ per hour

Ra1 500⁰ per hour

Ra1 750⁰ per hour

Ra1 500⁰ per hour

⁰F1 1200⁰ degrees

⁰F1 1500⁰ F

⁰F1 1500⁰ F

⁰F1 1000⁰ F

Hld1 30 minutes

Hld1 10 minutes

Hld1 5 minutes

Hld1 10 minutes

Ra2 500⁰ per hour

Ra2 Full per hour

Ra2 Full per hour

Ra2 Full per hour

⁰F2 1480⁰ degrees

⁰F2 950⁰ degrees

⁰F2 950⁰ degrees

⁰F2 1500⁰ degrees

Hld 2 20 minutes

Hld 2 30 minutes

Hld 2 30 minutes

Hld 2 10 minutes

Ra3 Full

Ra3 0000 Ends Program RA3 0000 Ends Program

Ra3 Full

⁰F3 950⁰ degrees

⁰F3 950⁰ degrees

Hld3 30 to 1 hour

Hld3 minutes

Ra4 200 per hour

Ra4 0000 Ends Program

⁰F4 700 degrees

*Full for the Bonnie Glo kiln

Hld4 0

***is about 1500⁰F per hour

Ra5 0000 Ends Program

***Using a rate of FULL in the first 1000 degrees of the firing is appropriate only for pieces less

than 3” squared and less than 3 layers thick. Larger pieces can go “FULL” after the first 1000

degrees, or as fast as the piece will tolerate. Taking the time to conduct a few test firings will go a

long way in knowing what your kiln can and cannot do for you.

Annealing

is an important step of a firing schedule to reduce stress. On the way down, hold

around 950°F for a length of time relative to the size of the pieces to help reduce internal stress.

(Bullseye's current recommended anneal temp is 900°F.) In a fiber kiln, jewelry sized pieces