Learning to Use the Lean Clean 360 Cleaning System

45

Inspection and

Maintenance

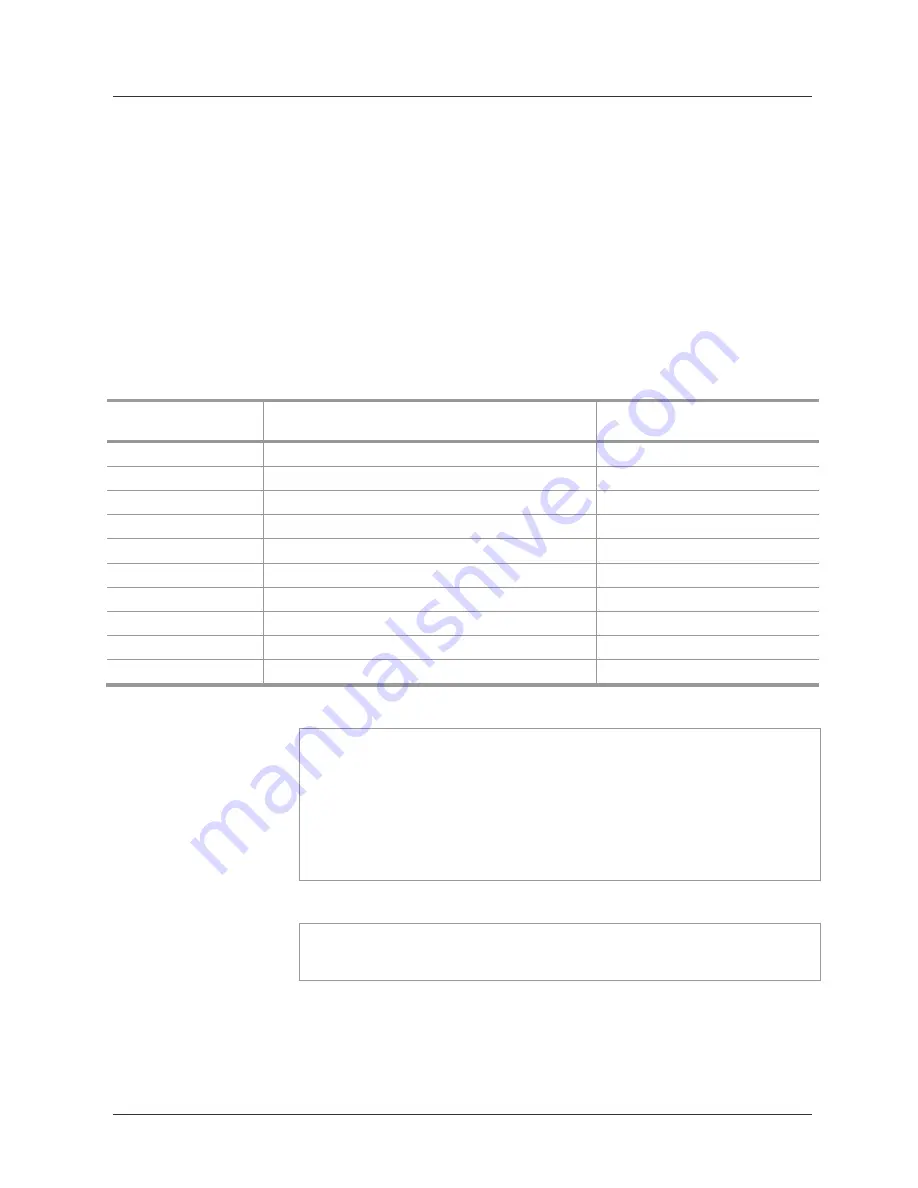

Inspection and Cleaning Chart

Performing the proper maintenance on your Lean Clean 360-1 will extend its

service life:

Component

What to Inspect

Frequency

Door seal

Seal

Daily

Chip baskets

Empty, inspect, and clean

Daily

Temperature probes

Inspect and clean

Weekly

Level probes/flats

Inspect and clean weekly.

Weekly

Rotator drum

Gears, support rings monthly, and flanged rollers

Monthly

Dryer

Inspect pressure duct

Monthly

Spray nozzles

Remove spray headers and clean nozzles

Periodically

Solution levels

Insure tanks are full

Before powering up the heaters

Temperature controls

Check for accuracy

Every six months

Tank heaters

Check for salts build-up

Weekly

Warning

—

Some inspection, cleaning, and maintenance operations expose

operators to risks (release of compressed air, release of hot process solution in

pressurized lines, electrical energy, pinching from unexpected startup). These risks

can cause bodily harm and death. To prevent bodily harm and death, follow your

plant’s safety

operating procedures and y

our plant’s lockout/tagout procedures for

electric, compressed air, and water supplies when performing inspection, cleaning,

and maintenance that exposes operators to these risks.

Expert Advice

—

All components inside the Lean Clean machine cabinet (not

the electrical control cabinet) are rated for washdown to simply cleaning.