Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing,

unless testing requires power and/or gas.

©2005 Maytag Services

16022089

15

Component Testing Procedures

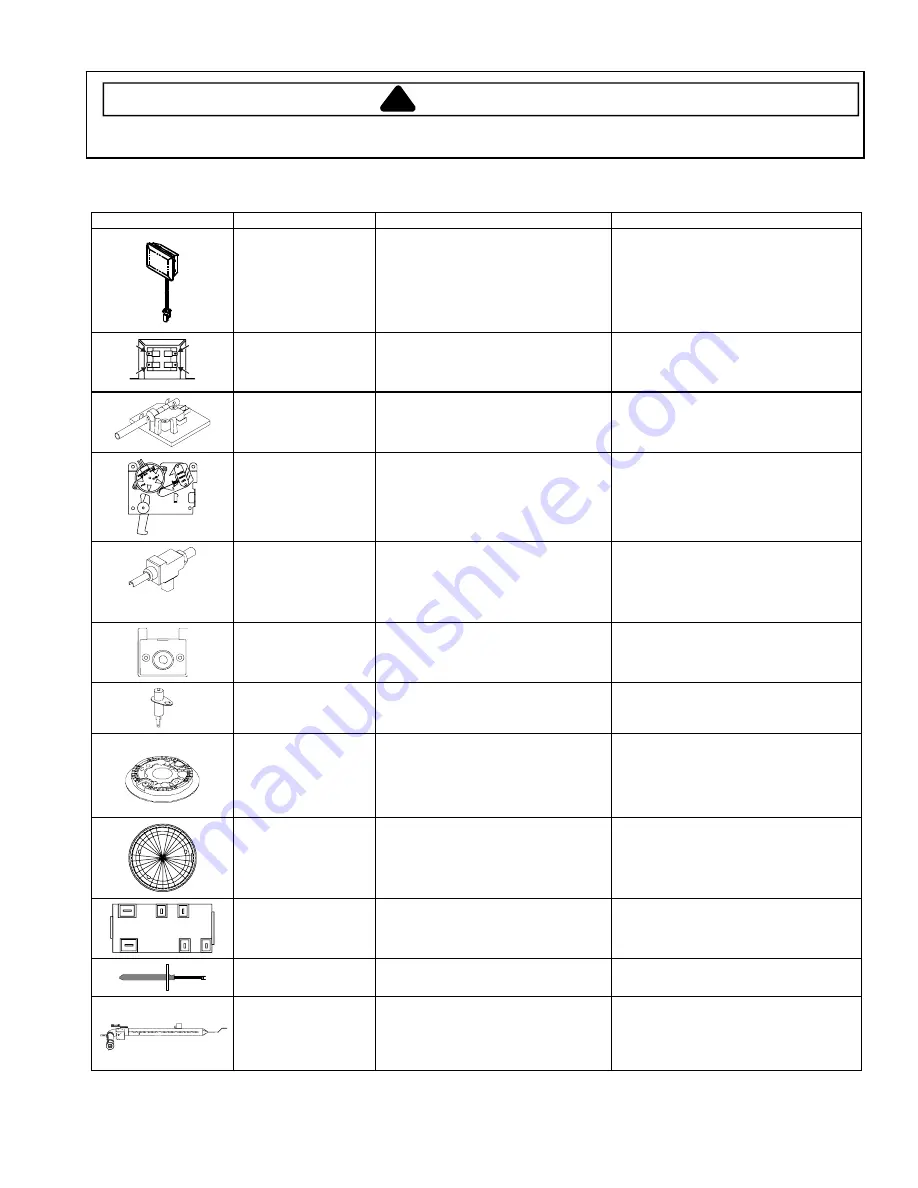

Illustration Component

Test

Procedure

Results

Oven light housing

Disconnect connector and test

resistance of terminals ...........................

Measure voltage at oven light ................

Verify bulb is plugged in properly.

Indicates continuity with bulb installed.

12 VAC, see wiring diagram for terminal

identification.

If no voltage is present at oven light,

check wiring or light switches.

Primary

Primary

Secondary

Secondary

Step-down

transformer

Measure voltage at:

Primary terminals ...............................

Secondary terminals...........................

120 VAC (tolerance: 108 to 127 VAC)

10W load (bulb): 11.4 to 11.8 VAC

20W load (bulb): 10.8 to 11.4 VAC

Door plunger switch

Remove switch from unit and measure

the following points:

COM to NO.........................................

Plunger in continuity, plunger out infinity.

Autolatch assembly

Disconnect wires and test for

continuity per wiring diagram.

Refer to Parts Manual for correct

autolatch switch associated with the

correct manufacturing number.

See wiring diagram for schematic layout.

Access assembly by removing right side

panel.

Common is in neutral position unless

locking or unlocking autolatch assembly.

270

°

valve

6.5 K btu

9.1 K btu

10.5 K btu

12 K btu

Verify gas is supplied.

Adjust set screw for simmer control.

Spark 270

°

switch

Test for voltage at terminals...................

Disconnect wiring and check for

continuity in LITE position ......................

120 VAC

Continuity in LITE position.

Spark ignition

electrode

Test for resistance of spark lead ............

Test ignitor to chassis ............................

Continuity

No continuity from ignitor to chassis.

Top surface burner

6.5 K btu,

9.1 K btu

10.5 K btu

12 K btu

Verify gas is supplied .............................

Verify burner cap is positioned

correctly.

Check for obstructions in burner ports.

Top surface burner

cap

Verify cap is positioned correctly............ Check for obstructions in burner ports.

L

A

B

A1

B1

N

Spark module 4 + 0

Test for voltage at terminals L and N .....

Check polarity and ground .....................

120 VAC (tolerance: 109 to 125 VAC)

See wiring diagram

Temperature sensor

Measure resistance................................ Approximately 1100

Ω

at room

temperature 75° F (23.8° C).

Broil burner

Verify gas is supplied.

Orifice adjusted for Natural or LP ...........

Check for obstructions or

contamination in ports............................

Factory set to Natural Gas.

Adjust as necessary.

Air shutter opening set to .281 to .343.

Replace if punctured or torn.

Summary of Contents for JGS8750ADB

Page 27: ... 2005 Maytag Services 16022089 A 1 Appendix A ...

Page 33: ... 2005 Maytag Services 16022089 B 1 Appendix B ...

Page 34: ...B 2 16022089 2005 Maytag Services Use Information ...

Page 35: ... 2005 Maytag Services 16022089 B 3 Use Information ...

Page 36: ...B 4 16022089 2005 Maytag Services Use Information ...

Page 37: ... 2005 Maytag Services 16022089 B 5 Use Information ...

Page 38: ...B 6 16022089 2005 Maytag Services Care Information ...

Page 39: ... 2005 Maytag Services 16022089 B 7 Care Information ...

Page 40: ...B 8 16022089 2005 Maytag Services Care Information ...

Page 41: ... 2005 Maytag Services 16022089 C 1 Appendix C ...