© 2006 Maytag Services

16026923

B – 11

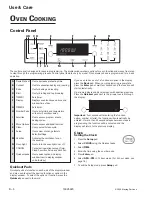

Use & Care

O

PTIONS

More Options

Cook & Hold

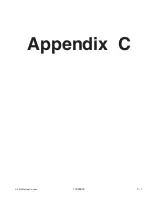

1. Press the

More Options

pad.

2. Select

COOK/HOLD

.

5. The display will show CONVECT DELAY, the selected function,

the preset temperature and the delay time countdown. When

the delay time has expired, the cook time will be displayed and

the oven will begin to preheat.

To set Delay Clean:

1. Follow “Delay” steps 1-4 (see below left).

2. REMOVE RACKS will show in the display. Remove the racks

from the oven and select

CONTINUE

.

3. Set

LIGHT

soil level by entering 200 using the number pads

for two hours of cleaning time. Select

MEDIUM

or

HEAVY

soil level using the Quickset pads. There is a brief delay while

the door locks.

4. DELAY CLEAN, the cleaning time, the delay time and unlock

time (based on the selected soil level) will show in the display.

When the delay time has expired, the clean time will be

displayed and the oven will begin to preheat.

For more information on self-cleaning, see pages 5-6.

3. Enter cook time using Quickset pads or the number pads.

4. Select

BAKE

or

CONVECT

.

5. When BAKE is pressed, select the temperature using

Quickset pads or the number pads.

6. When CONVECT is pressed, select

CNVT BAKE

or

CNVT

ROAST

then select the desired temperature using the

Quickset pads or the number pads.

The oven will cook for the selected time, then Keep Warm for

one hour. The oven will automatically turn off.

Important:

If the recipe recommends preheating the oven,

add 15 minutes to the cook time.

Delay

1. Press the

More Options

pad.

2. Press the arrow until DELAY is displayed.

3. Select

DELAY

.

4. Select Delay time using Quickset pads or the number

pads.

5. Select

BAKE

,

CONVECT

or

CLEAN

, then select

temperature using the Quickset or number pads.

To set Delay Bake:

1. Follow “Delay” steps 1-4 (see above).

2. Select from the displayed temperatures or use the

number pads to enter the temperature.

3. Select the time to cook from the displayed times or use

the number pads to enter the cooking time.

4. The display will show DELAY TIME, the selected function,

the preset temperature and the delay time countdown.

When the delay time has expired, the cook time will be

displayed and the oven will begin to preheat.

To set Delay Convect:

1. Follow “Delay” steps 1-4 (see above).

2. Select

BAKE

or

ROAST

.

3. Select from the displayed temperatures or use the

number pads to enter the temperature.

4. Select the time to cook from the displayed times or use

the number pads to enter the cooking time.

Notes:

• For any dough that requires one rise, either Standard or

Rapid Proofing can be used.

• When using frozen bread dough, choose

RAPID PROOFING

.

There is no need to thaw dough before proofing.

• For dough requiring two rises, Standard Proofing must be

used for the first rising period. Either Standard or Rapid

Proofing can be used for the second rise.

• If oven temperature is too high for proofing, OVEN COOLING

will appear in the display.

Proofing

The Proofing feature can be used to raise yeast-based bread

products prior to baking. There are two proofing methods

available – Rapid and Standard.

Standard proofing in the oven protects dough from room

temperature changes or drafts that commonly affect proofing

done on the countertop.

Rapid proofing provides faster proofing results than countertop

or Standard proofing, without harming the yeast.

1. Press

More Options

pad.

2. Select

PROOFING

.

3. Select

RAPID

or

STANDARD

.

4. When proofing is complete, remove the

dough from the oven and press the

CANCEL

pad.

CAUTION

Do not

use delayed baking for highly perishable foods such

as dairy products, pork, poultry, or seafood.